With the accelerating pace of industrialization and the growing global population, sourcing clean and safe drinking water has become a crucial challenge for commercial and industrial sectors. Reverse Osmosis (RO) treatment systems have emerged as a cornerstone technology to address this demand for high-quality potable water in diverse applications from bottling plants to municipal water stations. This guide explores the core technologies behind RO water treatment in commercial systems, detailing different equipment categories, their operational parameters, and scope of application in various industries.

Reverse Osmosis Membrane Systems: Core Technology for Purification

At the heart of any RO system lies the semi-permeable membrane that filters impurities and dissolved solids from raw water by applying high pressure. Commercial RO systems are designed with multi-stage membranes allowing removal of up to 99% of total dissolved solids (TDS), pathogens, and chemical contaminants. The typical TDS removal rate in well-configured systems can reach or exceed 95%-99%, aligning with World Health Organization (WHO) recommendations that consider TDS levels between 300 to 600 mg/L ideal for drinking water quality.

Commercial RO units are categorized based on capacity – ranging from small modular units producing under 1,000 liters per hour (LPH) suitable for retail water stores and clinics, up to large-scale systems yielding several hundred thousand LPH for municipal or industrial bottling plants. Modular designs now often integrate user-friendly control interfaces with remote monitoring capabilities for real-time performance optimization.

From my experience managing a brackish water RO project servicing a food processing plant, a system rated at 50,000 LPH successfully reduced TDS from an average 1200 mg/L to below 450 mg/L consistently, ensuring product water met strict beverage safety standards. This operation demonstrated how precise membrane selection and regular maintenance are critical for sustaining high-quality output under variable feedwater conditions.

Pretreatment: Filtration and Water Softening Essentials

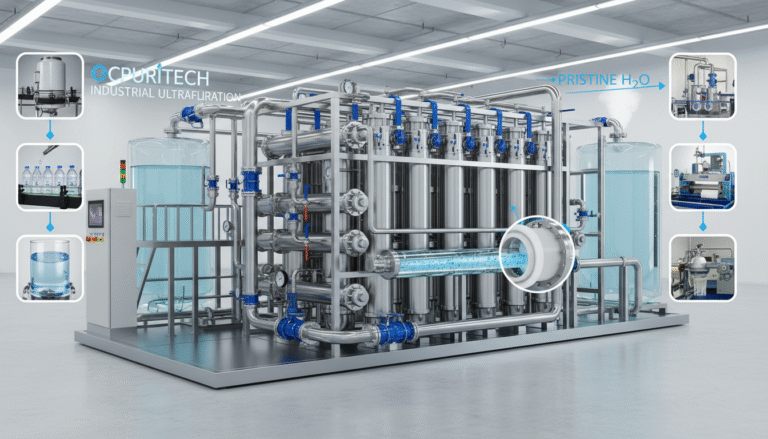

Effective pretreatment systems protect RO membranes and improve system longevity by removing suspended solids, chlorine, and hardness minerals, which can cause fouling and scaling. Common pretreatment equipment includes multimedia sand filters, activated carbon filters, and ion-exchange softeners. These components are tailored to the feedwater’s characteristics and the targeted final water quality.

Depending on the operational scale, pretreatment modules vary from compact cartridges for small commercial units to large fiberglass reinforced plastic (FRP) tanks for industrial systems. In heavy industry applications such as in semiconductor manufacturing or pharmaceutical water preparations, pretreatment systems are often coupled with Ultrapure Water (UPW) polishing stages to meet resistivity standards exceeding 18 MΩ·cm.

At one pharmaceutical facility I consulted, the use of sequential sand filtration, carbon treatment, and softening before RO and further polishing achieved ultrapure water with resistivity measurements at 18.2 MΩ·cm, perfectly meeting ASTM Type I water specifications for laboratory use.

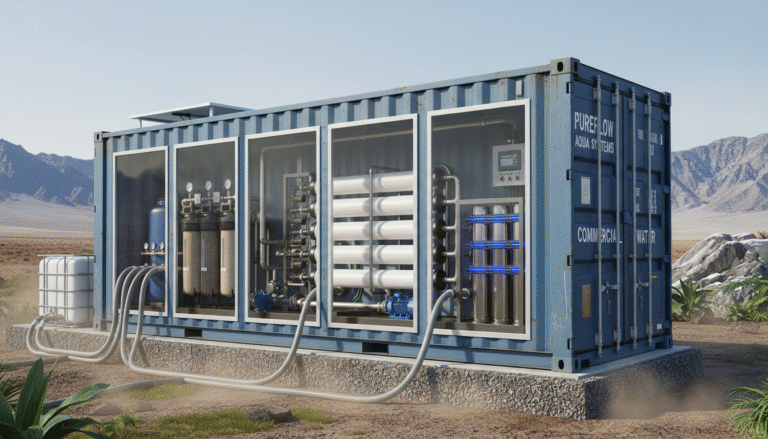

Containerized RO Systems: Mobility and Scalability

Containerized RO units are engineered for rapid deployment and mobility, often utilized in temporary worksites, disaster relief, or remote hospitality operations. These skid-mounted systems integrate full pretreatment, RO membranes, and post-treatment modules within standard freight containers for plug-and-play installation. Capacities generally range from 5,000 to 50,000 LPH.

Notably, these containerized solutions have proven invaluable in supplying drinking water on offshore marine platforms and for space mission analogs, where footprint and reliability are paramount. The compact design supports automated cleaning cycles and UV disinfection enhancement—a crucial step given that ultraviolet treatment achieves up to 99.99% inactivation of pathogens such as Cryptosporidium, using doses recommended at approximately 22 mJ/cm² as per EPA and NSF standards.

Based on projects I have overseen deploying containerized RO systems in coastal resorts, these systems enable economical desalination of brackish seawater while complying with stringent drinking water TDS limits, typically maintaining under 600 mg/L, thus ensuring regulatory compliance and customer satisfaction.

Cleaning and Sterilization: UV Disinfection and Maintenance Protocols

Routine maintenance of RO systems to prevent biofilm formation and scale buildup is critical for operational efficiency and water safety. Apart from chemical cleaning agents, ultraviolet (UV) sterilization units are widely installed in commercial RO systems as a non-chemical, physical disinfection barrier. UV disinfection, when applied at recommended doses, effectively neutralizes bacteria, viruses, and protozoa without introducing harmful residues.

In a municipal water treatment upgrade that I contributed to, addition of a UV unit following RO membranes resulted in a measurable reduction of microbial presence, effectively complementing the chemical-free reverse osmosis process. The system met local drinking water microbiological safety standards almost instantly after operation commencement.

Manufacturer Expertise and Quality Assurance

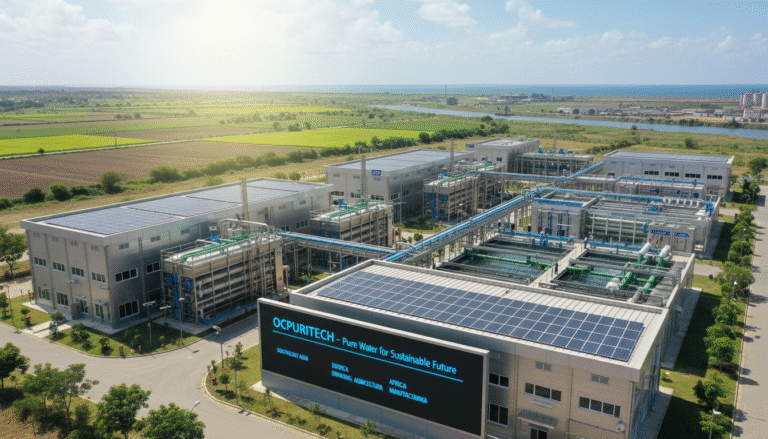

Manufacturers specializing in RO systems like Ocpuritech have developed extensive expertise over more than a decade, delivering advanced water treatment equipment backed by professional engineering support and rigorous quality control. Operating from large-scale factories in Guangzhou and Jiangmen, such providers support global customers across Southeast Asia, Africa, and South America with cost-effective, reliable equipment tailored to diverse industrial and commercial needs.

Their product portfolio spans brackish and seawater RO systems, ultrafiltration, nanofiltration, and ultrapure water systems, accompanied by comprehensive accessory lines including filter cartridges, carbon filters, UV units, and filling machines. This integrated approach ensures customers receive holistic solutions that meet application-specific standards—whether for drinking water, bottling, or high-purity process water.

Ocpuritech’s commitment to environmental responsibility aligns with their business philosophy: “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment,” as expressed by owner Carrie Chan.

Diverse Use Cases: From Seawater Desalination to Bottled Water Production

Apart from traditional industrial water treatment, commercial RO systems are widely adapted for seawater desalination in coastal regions, offering vital potable water supply where freshwater sources are scarce. Their modular designs also facilitate usage in portable water purification units for remote locations and military or space aesthetics drinking water production, demonstrating broad versatility.

In bottling lines, RO treated water ensures consistency and safety, crucial for beverages and bottled water factories. Agricultural operations benefit from customized RO pretreatment and softening to protect irrigation infrastructure and optimize water quality for irrigation or animal husbandry.

- Seawater desalination using multi-stage RO membranes for coastal utilities and resorts

- Portable containerized RO units for emergency and remote site water supply

- Integrated RO and polishing for pharmaceutical and semiconductor ultrapure water

- Bottled water production lines requiring stable TDS control and disinfection

Through practical implementations, we have observed water treatment designs that maintain TDS below 600 mg/L, UV sterilization ensuring 4-log microbial reductions, and ultrapure water resistivity standards achieved successfully in various commercial setups.

Conclusion

In summary, the commercial application of ro treatment of drinking water encompasses a sophisticated combination of membrane filtration, pretreatment, system configuration, and post-treatment sterilization to deliver clean, safe, and reliable water supply. Selecting appropriately scaled equipment, backed by manufacturers with strong technical expertise and quality assurance like Ocpuritech, empowers businesses and utilities to meet growing water demand efficiently.

As global water scarcity intensifies, embracing advanced RO technologies and complementary treatments becomes indispensable for industrial and commercial stakeholders seeking sustainable water management solutions.

References to Authoritative Sources

– World Economic Forum & Imperial College London, “Water demand in urban regions projected to rise by nearly 80% by 2050”

– World Health Organization (WHO), “Guidelines for Drinking Water Quality” – TDS quality standards

– Government of British Columbia, Canada, “Guidelines for Ultraviolet Disinfection of Drinking Water”

– Puretec Industrial Water, “Semiconductor Ultrapure Water Standards (18.2 MΩ·cm at 25°C)”