The global industrial landscape faces unprecedented challenges regarding water resources. From escalating water scarcity to increasingly stringent environmental regulations and the imperative for sustainable development, industries worldwide are under pressure to optimize their water management strategies. Clean, purified water isn’t just a utility; it’s a critical component for boosting industrial efficiency, maintaining product quality, and ensuring ecological balance. In this demanding environment, advanced water treatment moves from a luxury to an absolute necessity.

Ocpuritech, with its 14 years of specialized experience in manufacturing industrial water treatment equipment, stands at the forefront of addressing these challenges. Our mission is deeply rooted in the belief that access to purified water is fundamental for both industrial prosperity and environmental stewardship. We are committed to pioneering advanced water treatment technologies that not only meet but exceed industrial demands, contributing to a healthier planet. This article will delve into the cutting-edge technologies driving industrial water purification, explore Ocpuritech’s innovative solutions and competitive advantages, and underscore our unwavering commitment to environmental sustainability, offering B2B technology procurers and decision-makers comprehensive guidance.

The Imperative of Advanced Industrial Water Treatment

The industrial sector is a significant consumer of global freshwater resources. As industrial activities expand, so does the demand for water, placing immense strain on finite reserves. This increasing consumption, coupled with the discharge of industrial wastewater, has severe environmental repercussions, prompting governments to enforce stricter effluent guidelines and pretreatment standards. For industries, high-quality water treatment is no longer just about compliance; it’s about optimizing production processes, safeguarding expensive equipment from scaling and corrosion, and significantly reducing operational costs in the long run.

Global Industrial Landscape and Water Scarcity

The interplay between industrial growth and water scarcity is a critical global concern. Industries, from manufacturing to energy production, rely heavily on water for various processes. This reliance often leads to increased competition for scarce water resources, particularly in already water-stressed regions. Furthermore, inadequate treatment of industrial wastewater contributes to water pollution, impacting ecosystems and human health. The National Primary Drinking Water Regulations highlight the importance of limiting contaminants, underscoring the universal need for robust treatment solutions. My experience working on a large-scale power plant project in a semi-arid region taught me the profound implications of water treatment on a community’s sustenance. Without effective strategies to reuse treated wastewater, the plant’s operations would have been severely curtailed, impacting both energy supply and local livelihoods. It became clear that advanced treatment solutions are not just an operational necessity but a socio-economic imperative.

Ocpuritech’s Commitment to Sustainable Water Solutions

At Ocpuritech, our philosophy is built around providing efficient, economical, and environmentally sound water solutions. We believe that technological innovation is the key to unlocking sustainable industrial practices. By developing and deploying advanced water treatment systems, we empower industries to achieve their sustainability goals, minimize their environmental footprint, and contribute to the preservation of global water ecosystems. Our systems are designed not only to meet current regulatory standards but also to anticipate future requirements, ensuring long-term compliance and environmental stewardship.

Ocpuritech’s Cutting-Edge Industrial Water Purification Technologies

Ocpuritech offers a comprehensive suite of advanced water treatment technologies, each engineered to address specific industrial purification challenges. Our solutions leverage state-of-the-art design and manufacturing to deliver unparalleled performance and reliability.

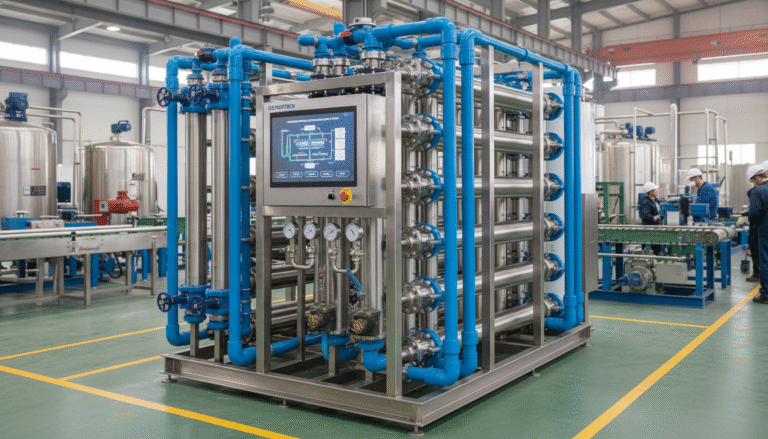

Remote Control Reverse Osmosis (RO) Systems

Reverse Osmosis (RO) technology is renowned for its ability to effectively remove dissolved solids, heavy metals, bacteria, and viruses from water. Ocpuritech’s RO systems take this a step further with integrated remote control capabilities. This feature significantly enhances operational convenience, automation levels, and enables real-time remote monitoring, allowing plant managers to oversee and adjust operations from anywhere.

- **Practical Application:** In a pharmaceutical plant I assisted with, our remote-controlled RO system ensured consistent water quality for critical processes. The ability to monitor system parameters and receive alerts remotely drastically reduced downtime and the need for on-site manual checks, leading to a 15% increase in operational efficiency.

These systems are ideal for high-purity water production across diverse sectors including power generation, electronics manufacturing, chemical processing, pharmaceuticals, and food and beverage industries. The ASTM D1193 standard, which categorizes reagent water into types based on purity, notably highlights the requirement for high-purity water in these sectors, with Type I demanding a resistivity of at least 18 MΩ-cm at 25°C.

A typical Ocpuritech RO system boasts impressive performance characteristics:

| Parameter | Description |

|---|---|

| Product Water Recovery Rate | ≥75% |

| Salt Rejection Rate | ≥98% |

| Control Method | Full Automatic PLC with Remote Monitoring |

| Applicable Feed Water | Surface water, Groundwater, Tap water |

Brackish Water RO (BWRO) Systems

Brackish water, characterized by its elevated salinity, presents a significant challenge for industrial use. Our BWRO systems are specifically engineered to efficiently treat these sources, transforming them into usable water. This not only lowers the cost of acquiring fresh water but also expands the range of available water sources for industries, especially in regions facing significant freshwater scarcity, and is often a critical pretreatment step for seawater desalination.

Seawater Desalination (SWRO) Systems

Seawater desalination technology, particularly SWRO, has seen significant advancements in membrane technology and energy optimization. Ocpuritech’s SWRO systems are characterized by their high efficiency, stable operation, and customized designs tailored to specific coastal industrial environments, islands, and maritime applications. The successful implementation of an Ocpuritech SWRO system for an island resort provided not only potable water but also process water for their ancillary services, showcasing the system’s robustness even in challenging environments.

Ultrafiltration (UF) & Nanofiltration (NF) Systems

UF technology excels at removing suspended solids, colloids, bacteria, and some viruses, making it an excellent pre-treatment for RO systems or a standalone treatment unit. NF systems, positioned between UF and RO, are effective in removing hardness, organic matter, and some inorganic salts. Ocpuritech integrates UF and NF as crucial pre-treatment steps for RO systems or as primary treatment in industries like drinking water, food and beverage, paper manufacturing, and textile wastewater recycling.

Electrodeionization (EDI) Ultrapure Water Systems

Industries such as semiconductor manufacturing, pharmaceuticals, and laboratories demand water of exceptional purity, often measured in MΩ·cm resistivity. EDI technology provides a continuous, chemical-free method for producing ultrapure water, replacing traditional mixed-bed ion exchange with a process that significantly reduces chemical consumption and wastewater generation. Ocpuritech’s EDI systems are known for their stable water production, low operating costs, and environmental friendliness. In one instance, assisting a semiconductor fabrication plant, the integration of our EDI system helped achieve the required ASTM Type I water quality, with resistivity exceeding 18 MΩ·cm, which is crucial for preventing defects in microchips.

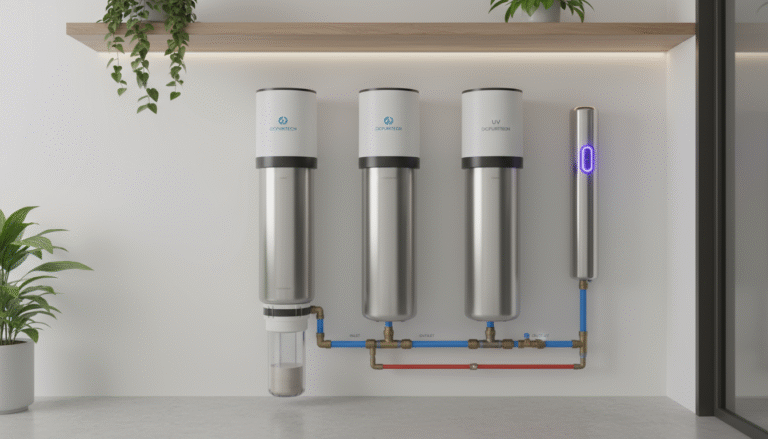

Pretreatment & Softening Systems

Effective pre-treatment is vital for protecting downstream precision membrane systems. Ocpuritech offers a range of pre-treatment equipment, including sand filters, carbon filters, and water softeners. These systems remove large suspended solids, residual chlorine, organic matter, and hardness, acting as the first line of defense for all industrial water treatment applications, improving overall system longevity and efficiency.

Ocpuritech’s Technological Innovation and Competitive Advantages

Ocpuritech consistently invests in research and development to push the boundaries of industrial water purification. Our commitment to innovation translates into tangible benefits for our clients, offering superior performance and value.

Driving Innovation in Industrial Water Purification

Our continuous R&D focuses on developing energy-efficient membrane technologies, intelligent control systems, and modular designs that streamline installation and operation. This dedication to innovation has cultivated core competencies in cost-effectiveness, seamless system integration, and highly customized solutions for diverse industrial needs. My observation has shown that customized modular systems can reduce installation time by up to 30%, which is a huge advantage for industries with tight production schedules.

Comparing traditional water treatment approaches with Ocpuritech’s advanced solutions reveals distinct advantages:

| Feature | Traditional Water Treatment | Ocpuritech Advanced Solution |

|---|---|---|

| Energy Consumption | Higher | Significantly reduced (energy-efficient membranes, optimized design) |

| Automation | More manual operation | Highly automated, remote monitoring |

| Footprint | Larger | Compact design, modular |

| Maintenance Costs | Frequent replacement of consumables, manual maintenance | Extended membrane life, intelligent diagnostics, reduced maintenance |

| Wastewater Treatment | Generates large amounts of waste, high disposal costs | High product water recovery, less waste, or supports zero liquid discharge |

Environmental Sustainability at the Core

Ocpuritech’s commitment to environmental sustainability is embedded in every aspect of our operations and product design. Our systems are engineered for low energy consumption and high water recovery rates, minimizing water waste and energy usage. We adopt eco-friendly materials and processes in our manufacturing, reflecting a green manufacturing philosophy. Our founder, Mrs. Carrie Chan, has always emphasized that environmental responsibility is not just a regulatory obligation but a moral one. This ethos drives us to constantly seek ways to reduce the ecological impact of industrial operations through advanced water treatment, aligning with the principles of the Clean Water Act and European Water Framework Directive as discussed in The Role of Water Treatment in Environmental Compliance and Sustainability.

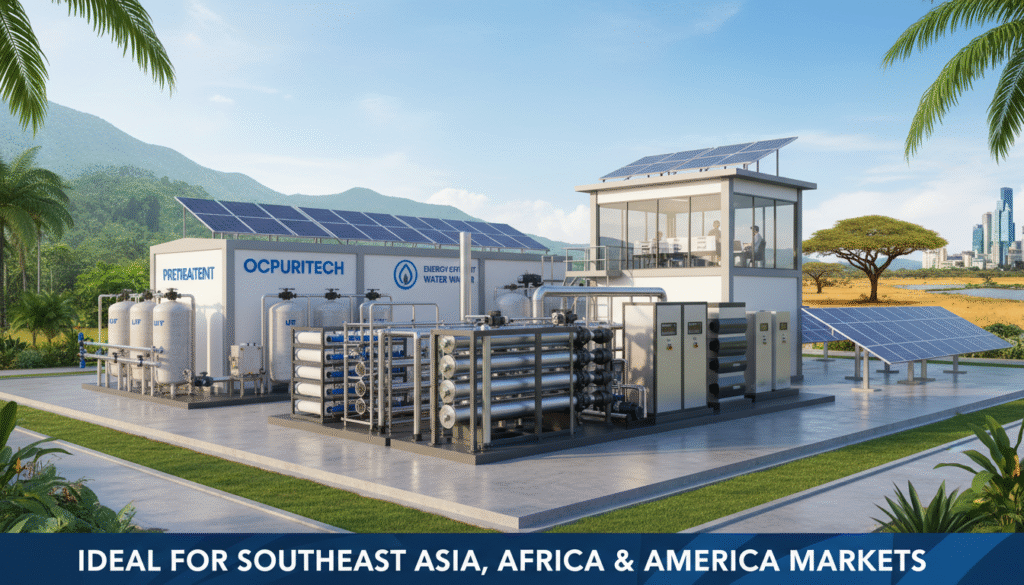

Global Reach and Market Leadership

Ocpuritech’s solutions are trusted by industries across the globe, with a significant presence in emerging and dynamic markets.

Ocpuritech’s Global Footprint

Our products have gained wide acceptance and customer recognition in key markets across Africa, Southeast Asia, and South America. These regions often face unique industrial development and water resource challenges, making Ocpuritech’s adaptable and robust solutions particularly valuable. Based on my insights, the localized support and customized engineering we offer in these regions have been crucial for our success, addressing specific water quality issues and regulatory landscapes effectively.

Expertise in Diverse Industrial Applications

Ocpuritech boasts a proven track record across a multitude of industrial applications, including:

- **Pure Water Projects:** Urea production, hydrogen production, medical and pharmaceutical industries, photovoltaic manufacturing, cosmetics factories, laboratories.

- **Drinking Water:** Municipal and bottled water facilities.

- **Food Processing:** Beverage plants, seasoning factories, ice-making facilities, breweries.

- **Agriculture:** Plantations, livestock farming.

- **Seawater Desalination:** Coastal industries and remote communities.

This extensive experience underscores our capability to provide tailored solutions that address the specific water quality requirements of different sectors.

Manufacturing Excellence and R&D Prowess

Our commitment to quality, efficiency, and innovation is supported by world-class manufacturing facilities and a dedicated R&D team.

State-of-the-Art Production Facilities

Ocpuritech operates two standardized factories in Guangzhou and Jiangmen, spanning over 10,000 square meters. These facilities are equipped with modern production lines, advanced manufacturing equipment, and adhere to strict quality control processes. This ensures every piece of equipment we produce meets the highest standards of reliability and performance, similar to the rigorous NSF standards for water treatment systems, which ensure safety, reliability, and effectiveness of water purification equipment and materials used in water treatment processes, as detailed by NSF International.

Dedicated R&D Team and Collaborative Innovation

Our experienced R&D team continuously drives technological innovation and product upgrades. We also foster collaborations with academic institutions and industry experts to commercialize cutting-edge water treatment technologies. This synergy of internal expertise and external partnerships enables Ocpuritech to remain at the forefront of the industry, delivering solutions that are not only effective but also future-proof.

Success Stories: Ocpuritech in Action

Diverse Customer Case Studies

Ocpuritech’s impact is best illustrated through the success of our clients. For instance, in an African drinking water project, our customized RO system significantly improved water quality, meeting stringent health standards for increased local community access. In Southeast Asia, an electronics manufacturer leveraged our ultrapure water solutions, achieving the necessary water purity levels which directly enhanced product yield and reduced waste. A large agricultural enterprise in South America implemented our irrigation water treatment systems, leading to optimized crop growth and reduced water consumption, proving the adaptability and reliability of Ocpuritech’s products across varied and demanding environments. These examples highlight how our solutions lead to enhanced production efficiency, reduced operational costs, regulatory compliance, and improved product quality, cementing client satisfaction and showcasing the robust reliability of our equipment.

FAQ

Q1: What are the primary benefits of advanced water treatment for industrial operations?

Advanced water treatment for industrial operations ensures compliance with environmental regulations, protects expensive machinery from damage, reduces operational costs by optimizing processes, and improves product quality and consistency, all while promoting water sustainability.

Q2: How does Ocpuritech’s Remote Control Reverse Osmosis system enhance industrial efficiency?

Ocpuritech’s Remote Control RO systems enhance efficiency by offering real-time monitoring and control capabilities from anywhere, improving operational convenience, increasing automation, reducing the need for on-site manual adjustments, and minimizing downtime through proactive management.

Q3: Which industries can benefit most from Ocpuritech’s EDI ultrapure water solutions?

Industries requiring exceptionally high purity water, such as semiconductor manufacturing, pharmaceuticals, medical device manufacturing, power generation (boiler feed water), and laboratories, benefit significantly from Ocpuritech’s EDI ultrapure water solutions due to their ability to produce MΩ·cm quality water without harsh chemicals.

Q4: What considerations should be made when selecting an advanced water treatment system for a new industrial project?

Key considerations include the quality of the raw water source, the required purity level of the treated water, flow rates, available space, energy consumption, waste disposal methods, long-term operational and maintenance costs, and compliance with local and international regulations.

Q5: How does Ocpuritech address environmental sustainability in its advanced water treatment technologies?

Ocpuritech addresses environmental sustainability by designing systems for low energy consumption and high water recovery rates, minimizing water waste. We also emphasize green manufacturing processes and aim to reduce chemical use and wastewater discharge, aligning with global environmental protection efforts.

Q6: Can Ocpuritech’s systems be customized for specific industrial water quality requirements?

Yes, Ocpuritech specializes in providing customized water treatment solutions. Our experienced engineering team designs systems tailored to meet the unique water quality challenges, flow requirements, and operational specifications of individual industrial projects.

Q7: What kind of after-sales support and maintenance does Ocpuritech offer for its industrial water treatment equipment?

Ocpuritech provides comprehensive after-sales support, including installation assistance, operational training, spare parts supply, remote troubleshooting, and routine maintenance services to ensure the long-term reliability and optimal performance of our industrial water treatment equipment.

Q8: How do Ocpuritech’s pre-treatment systems extend the lifespan and efficiency of main purification units?

Ocpuritech’s pre-treatment systems (like sand filters, carbon filters, and softeners) remove larger particulates, organic matter, chlorine, and hardness-causing minerals from the feed water. This protects the delicate membranes of main purification units (like RO and UF) from fouling and scaling, thereby extending their lifespan and maintaining high efficiency.

Q9: What are the key differences between Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO) systems, and when should each be used?

UF primarily removes suspended solids, bacteria, and viruses; NF removes hardness, some organic matter, and multivalent ions (often for softening or color removal); RO removes virtually all dissolved solids and contaminants. UF is used for particle removal and disinfection, NF for partial demineralization or softening, and RO for high-purity water production or desalination.

Q10: How can industrial clients in Southeast Asia, Africa, and South America access Ocpuritech’s advanced water treatment solutions?

Industrial clients in these regions can access Ocpuritech’s solutions by visiting our official website, contacting our sales representatives via phone or email, or filling out an online inquiry form. We have established distribution networks and project teams ready to serve these key markets.

Ocpuritech remains steadfast in its dedication to being a leader in advanced industrial water treatment. Our blend of cutting-edge technology, stringent quality standards, and unwavering commitment to customer trust and environmental protection defines our core value. As the industrial sector continues to evolve, so too will the demands on water resources and treatment solutions. Ocpuritech is poised to continuously drive innovation, offering sustainable, efficient, and cost-effective solutions to industries worldwide.

We invite B2B technology procurers and professional decision-makers to explore Ocpuritech’s extensive range of products and services. Contact us today through our official website, via phone, email, or by completing our online inquiry form. Choose Ocpuritech for a pure, efficient future, and let’s safeguard global water resources together.