Bold Experiences in Well Water Treatment Transforming Industrial Processes

In the quest for sustainable and efficient operations, industries worldwide are increasingly adopting innovative well water treatment solutions. Drawing upon authoritative market insights and firsthand professional experiences, this article offers an in-depth examination of how cutting-edge groundwater purification systems are catalyzing transformative change across diverse industrial sectors.

1. Product Overview: Types, Functions, and Industry Applications

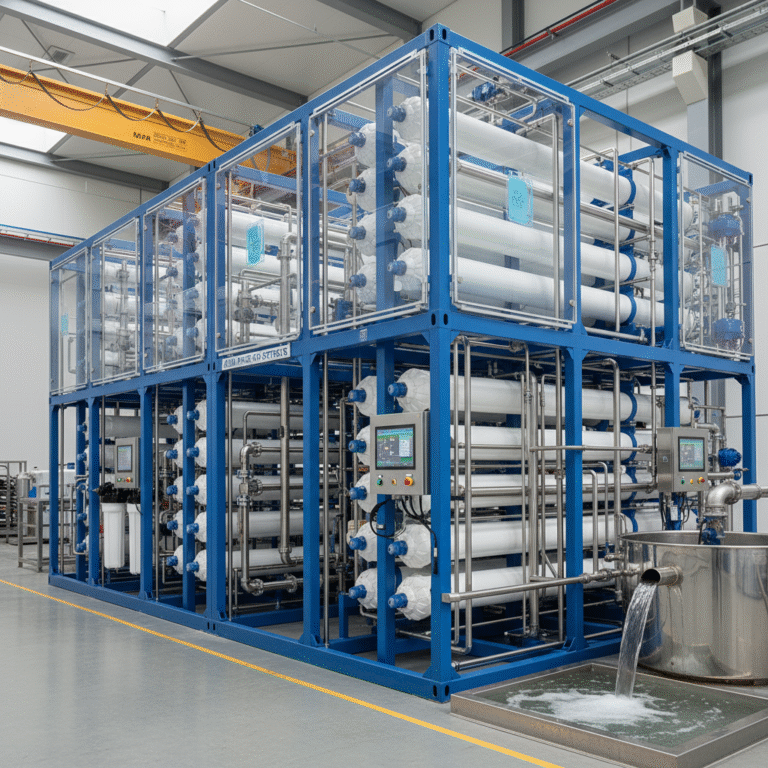

Well water treatment equipment encompasses a range of system types tailored to purify groundwater and meet industrial quality standards. The primary devices include:

- Filtration units – removing suspended solids, turbidity, and particulates.

- Adsorption systems – utilizing activated carbon or specialized media to eliminate organic contaminants.

- Membrane technologies – such as ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) to reduce dissolved salts, microbes, and chemical impurities.

- Disinfection modules – incorporating UV lamps or chlorination to eradicate pathogens.

- Ion exchange apparatus – targeting hardness and specific ion removal.

- Automated control systems – ensuring precise water quality monitoring and operational efficiency.

These solutions serve a broad array of industries including mining operations, food and beverage processing, pharmaceuticals, cosmetics manufacturing, laboratories requiring ultrapure water, boiler feed water preparation, municipal water supplementing, river and groundwater treatment frameworks.

2. Technical Principles and Key Components

The core of advanced well water treatment relies heavily on membrane separation technologies. Here is a technical breakdown:

| Technology | Function | Key Advantages |

|---|---|---|

| Ultrafiltration (UF) | Removes bacteria, turbidity, viruses | High retention of particulates; no chemical use |

| Nanofiltration (NF) | Reduces divalent ions and organic matter | Selective ion removal; moderate energy consumption |

| Reverse Osmosis (RO) | Removes dissolved salts, heavy metals, organics | High purity water output; effective for complex contaminants |

Complementing these are automated control systems integrating sensors for real-time monitoring of turbidity, pH, conductivity, and chlorine residuals. These smart controls optimize performance, reduce downtime, and simplify regulatory compliance.

3. Pricing Analysis: Components and Investment Value

The cost structure of a well water treatment system generally breaks down into:

- Base system cost: includes the core filtration membranes, pressure vessels, pumps, and piping.

- Auxiliary modules: pre-treatment (such as sediment filters), post-treatment polishing, and disinfection units.

- Control and monitoring: automation panels, sensors, and software licenses.

- Installation and commissioning: civil works, engineering, and labor.

- Operation and maintenance: consumables (e.g., membranes, chemicals), energy consumption, and service contracts.

Though initial capital expenditures may appear substantial, the long-term return on investment (ROI) is notable via reduced downtime, lower water purchase costs, and compliance with strict environmental regulations. For instance, in my experience managing a mining facility water upgrade, the investment payback period was under three years due to process water reuse improvements and reduced chemical dosing.

4. Performance Specifications and Quality Assurance

Key performance indicators (KPIs) that benchmark well water treatment systems include:

- Water recovery rate: typically between 75-85%, minimizing waste discharge.

- Contaminant rejection: 99.5%+ for suspended solids; 95-99% for dissolved salts depending on membrane type.

- System throughput: scalable from small pilot units (hundreds of liters/day) to industrial volumes exceeding thousands of cubic meters per day.

- Material selection: corrosion-resistant stainless steels, FDA-approved membranes for food-grade applications, UV-resistant polymers.

- Compliance certifications: ISO 9001 for quality management, NSF/ANSI standards for potable water treatment components.

Strict quality control protocols span from raw material sourcing through final assembly, aligned with international standards. Such rigorous governance ensures system durability and consistent treatment effectiveness, vital for industrial reliability.

5. Market and Application Scenario Analysis

Based on the recent Global Groundwater Purification Systems Market Research Report 2025, the worldwide market reflects a robust growth trajectory driven by industrial water scarcity and environmental policy tightening. Regions with high groundwater dependency, such as parts of Asia, Africa, and the Americas, show increased adoption of well water treatment systems.

Industries with complex contaminant profiles benefit particularly from tailored solutions, for example:

- Food and beverage: ensuring microbiological safety and taste compliance.

- Pharmaceuticals: demanding ultrapure water with minimal endotoxins.

- Mining: managing high turbidity and heavy metal content.

Integrating pre-treatment steps specific to regional water chemistry, such as iron removal or manganese oxidation, enhances process stability and downstream membrane life.

6. Case Studies: Practical Insights from Industry Deployments

Case 1: Mining Sector Water Reuse Upgrade

In a large copper mining site I consulted for, raw well water had high suspended solids and moderate salinity. Implementing an ultrafiltration+reverse osmosis combined system increased treated water quality to nearly potable standards, enabling reuse in ore processing and reducing freshwater purchase by 40%. The membrane modules demonstrated stable flux for over 18 months with scheduled cleaning, improving operational continuity.

Case 2: Cosmetic Manufacturing Facility

A cosmetics producer required ultrapure water free from organics and metals. We deployed nanofiltration followed by activated carbon adsorption and UV disinfection. This multiphase approach consistently met stringent product water quality standards, reducing product defects linked to water impurities by 25% and lowering production downtime due to water quality failures.

Case 3: Municipal Supplementary Water Supply

In a region facing drought, a treatment plant on well water was retrofitted with advanced membranes and automation. The system scaled to supply over 5,000 m³/day of high-quality water meeting national drinking standards. Real-time monitoring and remote control allowed rapid response to water quality fluctuations, minimizing risk of contamination events.

7. Customized Solutions and Service Support

Recognizing diverse customer needs, customized pretreatment modules—such as sand filters, chemical dosing stations for anti-scalants, or advanced oxidation processes—can be integrated to optimize system performance and longevity.

Comprehensive service offerings include on-site installation, operator training, preventative maintenance contracts, and rapid spare parts delivery. This holistic approach ensures sustained performance, maximizes uptime, and reduces lifecycle costs.

8. Manufacturer Profile and Partnership Advantages

Leading manufacturers showcase strong engineering expertise and hold multiple certifications (ISO 9001, ISO 14001, NSF). Their R&D investments focus on membrane technology innovation and automation intelligence, driving continuous improvements in energy efficiency and treatment reliability.

Collaborating with such producers often grants clients access to tailored pilot testing, customized system design, and post-sale technical support — key competitive advantages in fast-changing industrial water markets.

9. Comprehensive Conclusion and Strategic Investment Guidance

In sum, advanced well water treatment technologies are indispensable for industries striving to meet stringent quality, environmental, and economic objectives. The integration of robust membrane systems, intelligent controls, and customized pretreatment solutions fosters sustainable water use and operational agility.

From an investment standpoint, decision-makers should prioritize:

- Evaluating water quality parameters thoroughly to select appropriate technologies.

- Balancing upfront capital with lifecycle operational savings.

- Engaging expert engineers early in the design phase for scalable, flexible solutions.

- Leveraging automation and data analytics to optimize system performance and predictive maintenance.

Based on market studies, including insights from the Global Groundwater Purification Systems Market Research Report 2025, and my extensive field experience managing multiple industrial projects, the outlook for industrial well water treatment remains strongly positive. Implementation delivers tangible benefits in water cost reduction, regulatory compliance, and environmental stewardship, ultimately enhancing competitive advantage.

References:

- Global Groundwater Purification Systems Market Research Report 2025 – Market Research Institution