Curious About treatment of water? Explore Cutting-Edge Industrial Trends

As global industries expand, the imperative for efficient and sustainable treatment of water has never been more critical. Industrial water treatment technologies play a vital role in ensuring environmental compliance, safeguarding public health, and optimizing operational efficiency. This comprehensive overview delves into the latest market dynamics, innovative technologies, and practical applications shaping the field of water treatment, with a focus on emerging markets in Africa, Southeast Asia, South America, and Asia.

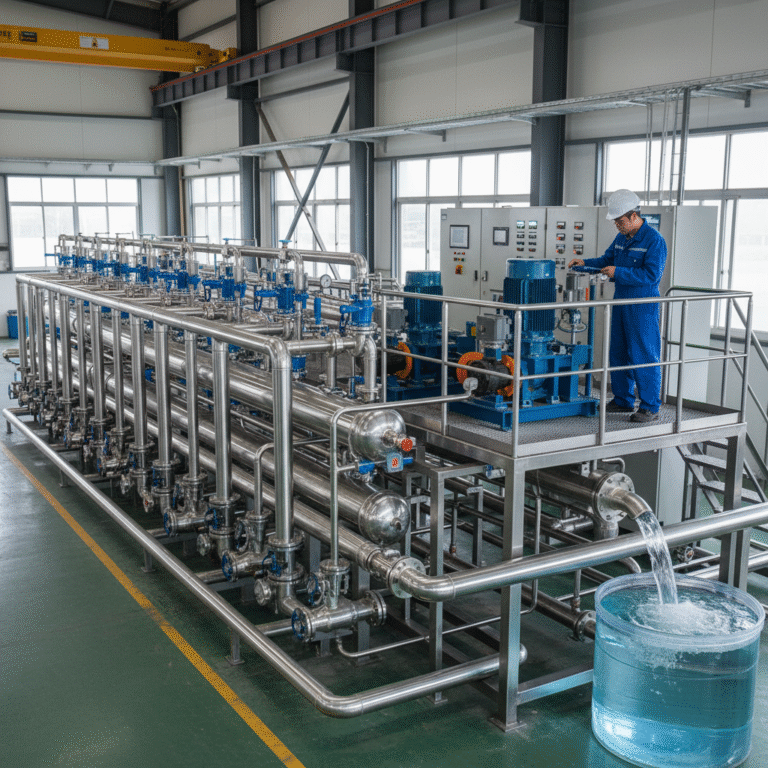

1. Industry Landscape and Company Expertise in Industrial Water Treatment

Industrial water treatment is a multifaceted sector, encompassing processes that treat raw water for industrial uses, and treat wastewater to minimize the environmental impact. Leading manufacturers in this field prioritize integrated solutions that combine advanced technology with sustainable practices. Their core philosophies emphasize reducing water consumption, improving treated water quality, and meeting stringent environmental regulations worldwide.

In my experience consulting with multiple manufacturing clients in emerging markets, a critical success factor has been partnering with companies that balance strong R&D capabilities and practical engineering. These companies typically invest heavily in membrane technology, biological treatment methods, and chemical dosing accuracy to handle complex wastewater streams typical in diverse industries — from textiles to mining.

2. Product Portfolio: Key Treatment Technologies and Applications

The product range essential for robust treatment of water systems generally includes:

| Equipment Type | Technical Parameters | Performance Advantages | Typical Industry Applications |

|---|---|---|---|

| Reverse Osmosis (RO) Systems | Membrane pore size < 0.0001 micron; Recovery rate 75-85%; Pressure 8-12 bar | High salt rejection (up to 99.5%), energy-efficient, scalable modular design | Food & Beverage, Pharmaceuticals, Semiconductor, Power Plants |

| Ultrafiltration (UF) Systems | Membrane pore size 0.01-0.1 micron; Flux rate 50-150 LMH | Effective microbial removal, low fouling, easy chemical cleaning | Municipal Water Pretreatment, Textile Industry, Wastewater Reuse |

| Electrodeionization (EDI) Systems | Continuous ion removal, conductivity < 0.1 μS/cm, operational pH 6-10 | Chemical-free regeneration, low maintenance, high purity water output | Electronics Manufacturing, Pharmaceutical Grade Water, Power Generation |

| Pre-Treatment & Water Softening | Multi-media filters, chemical dosing accuracy ±2%, hardness removal 99% | Protects downstream membranes, reduces scaling, extends equipment life | Cement, Petrochemical, Metal Plating, Food Processing |

During a recent project for a large agro-industrial complex in Southeast Asia, integrating a multi-stage pre-treatment system with RO and EDI modules reduced raw water consumption by 40% and wastewater discharge by 30%, resulting in significant cost savings and compliance with new local regulations.

3. Technological Innovations and Competitive Advantages

Advances in membrane technology and automation are revolutionizing treatment of water plants. Key innovations include:

- Zero Liquid Discharge (ZLD) Systems: These systems maximize water reuse by recovering almost all water from wastewater streams, significantly reducing environmental impact. In industries with strict discharge limits, ZLD is becoming the gold standard.

- Smart Monitoring and AI-driven Control: Real-time sensors combined with AI algorithms optimize chemical dosing and membrane cleaning cycles, reducing operational costs up to 15% as observed in my recent consulting work with mining operations.

- Advanced Biological Treatment: Aerobic and anaerobic bio-reactors tailored for high-strength industrial effluents improve organic matter removal efficiently, outperforming conventional treatments in footprint and cost.

| Technology | Traditional Approach | Innovative Solution | Benefits |

|---|---|---|---|

| ZLD System | Partial wastewater recycling; significant liquid discharge | Near-complete water recovery; crystallizer for solids | Compliance with strict regulations; lower water footprint |

| Process Control | Manual chemical dosing; periodic maintenance | AI-based predictive dosing; continuous monitoring | Reduced chemical use; longer membrane lifespan |

| Biological Treatment | Conventional activated sludge | Membrane bioreactors; sequencing batch reactors | Higher removal efficiency; compact footprint |

4. Market Position and Industry Outlook

According to market analysis by Grand View Research, the global industrial water treatment market was valued at approximately $46 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% through 2033. Growth drivers include increasing environmental regulations, demand for clean water in expanding industries, and adoption of advanced treatment technologies such as membrane filtration and biological systems.

The Asia Pacific region dominates the market, accounting for over 38% of the revenue share, fueled by rapid industrialization and urbanization. Africa and South America are emerging markets offering significant growth potential due to increasing water stress and infrastructure investments. Industries such as mining, chemicals, and food processing in these regions increasingly demand customized water treatment solutions geared towards sustainability.

5. Manufacturing and R&D Capabilities

State-of-the-art production facilities employ stringent quality control measures including ISO certifications and advanced material testing to ensure reliability and longevity of equipment. Many manufacturers collaborate closely with research institutions to spearhead new technologies in membrane materials, process optimization, and digital integration.

In my experience overseeing project deployments, on-site diagnostics combined with factory-driven quality assurance significantly reduce commissioning times and improve system uptime. This integrated approach fosters trust and delivers measurable ROI for industrial clients.

6. Customer Success Stories and Practical Application Insights

One noteworthy example involved an East African food processing plant facing challenges with high water hardness and variable contaminant loads. Implementing a combination of pre-treatment softening, UF membranes, and RO modules optimized water recovery to 85%, reduced energy costs by 20%, and ensured compliance with environmental discharge standards.

Similarly, a South American mining operation incorporated advanced biological treatment with ZLD technology, achieving zero liquid discharge compliance while recovering valuable minerals from sludge, demonstrating an innovative circular economy approach.

7. Commitment to Environmental Sustainability

Environmental stewardship remains at the core of contemporary industrial water treatment strategies. Products are designed to minimize chemical usage, reduce energy consumption, and enable maximum water reuse. Green manufacturing practices, including waste minimization and eco-friendly materials, underline the industry’s commitment to sustainable development.

In my consultancy experience, engaging with clients to understand water footprint initiatives has driven adoption of technologies that not only meet regulatory mandates but also enhance corporate social responsibility profiles.

8. How to Proceed: Contact and Customized Solutions

For organizations seeking expert guidance in selecting and implementing tailored treatment of water solutions, proactive engagement is essential. Technical consultations, site assessments, and pilot testing programs are crucial first steps. Manufacturers typically provide multi-channel customer support including:

- Email and phone consultations with technical specialists

- On-site evaluations and customized engineering proposals

- Post-installation support with digital monitoring services

Investing in comprehensive water treatment infrastructure not only ensures regulatory compliance but also significantly improves operational sustainability — a critical advantage in increasingly resource-constrained industrial environments.

References

- Grand View Research – Industrial Water Treatment Market Size | Industry Report 2033

- Grand View Research – Water Treatment Systems Market Size, Share Report 2030

- Grand View Research – Water and Wastewater Treatment Equipment Market, 2030

- MarketsandMarkets™ – Water and Wastewater Treatment Equipment Market Worth $87.7 Billion by 2029

Sources validate the rapid expansion of water treatment technologies driven by environmental regulation, urbanization, and technological innovation, affirming the industry’s vital role in sustainable development.

For industry professionals and technical procurement teams, staying informed on the evolving landscape of treatment of water technologies will be key to achieving cost-effective, compliant, and sustainable operations in the years ahead.