Elevating Industrial Water Treatment: A Comprehensive Overview of Cutting-Edge Equipment and Solutions

Industrial water treatment is a cornerstone in safeguarding environmental sustainability and operational efficiency across various sectors worldwide. The manufacturing of specialized water treatment equipment plays a pivotal role in enabling industries to meet strict regulatory standards while reducing their ecological footprint. This article delves into the current landscape of industrial water treatment technology, emphasizing innovation, product series, manufacturing excellence, and its transformative implications for emerging markets, particularly in Africa, Southeast Asia, South America, and Asia.

1. Industry Landscape and Company Framework

The industrial water treatment equipment sector has evolved dramatically, driven by heightened environmental concerns and stringent compliance mandates. Leading manufacturers prioritize advanced research and development (R&D) to design systems that are both robust and environmentally responsible.

Core tenets guiding these enterprises include:

- Technical Excellence: Persistent innovation in membrane technology, oxidation systems, and control automation.

- Environmental Stewardship: Commitment to sustainability through energy-efficient processes and waste minimization.

- Global Collaboration: Strategic cooperation with research institutions and regulatory bodies worldwide.

Within this framework, industrial water treatment emerges not merely as a technical challenge but as a critical driver for ecological balance and resource reuse. These efforts ensure water-intensive industries such as manufacturing, power generation, and food processing operate sustainably.

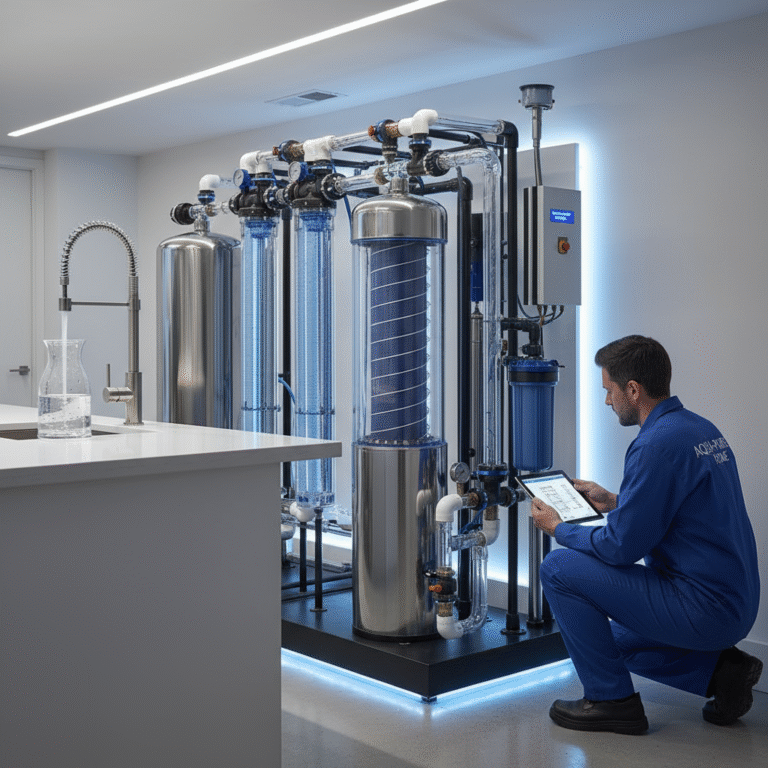

2. Comprehensive Product Portfolio

A versatile product line addressing diverse industrial water purification needs includes:

2.1 Reverse Osmosis (RO) Systems

RO technology remains the gold standard for high-purity water production, utilizing semi-permeable membranes to selectively remove dissolved salts, organic contaminants, and microbial impurities.

- Technical Parameters: Membrane permeability >99%, feed water TDS tolerance up to 5000 ppm, flux rates adjustable between 10-50 m³/day

- Performance Advantages: High salt rejection, low energy consumption (optimized pumps and energy recovery devices), modular design for scalability

- Applicable Industries: Semiconductor manufacturing, pharmaceutical production, and power plants

2.2 Ultrafiltration (UF) Systems

UF serves as a pre-treatment or standalone solution by removing suspended solids, colloids, bacteria, and large molecular weight organics, ensuring downstream process protection.

- Technical Parameters: Membrane pore size 0.01-0.1 micron, maximum operating pressure 3 bar

- Performance Advantages: High retention of pathogens, minimal chemical usage, automatic backwash capabilities

- Applicable Industries: Food and beverage, municipal water augmentation, textile processing

2.3 Electrodeionization (EDI) Units

EDI integrates ion exchange resins and electricity to continuously produce ultrapure water without the need for chemical regenerants.

- Technical Parameters: Conductivity < 0.1 µS/cm, operating pressure up to 5 bar

- Performance Advantages: Continuous ion removal, reduced operational costs, environmentally friendly

- Applicable Industries: Electronics manufacturing, laboratory-grade water preparation

2.4 Pre-treatment and Water Softening Systems

This segment includes media filters, activated carbon adsorbers, and ion exchange softeners designed to remove hardness, turbidity, and chlorine, protecting downstream membranes and equipment.

- Technical Parameters: Hardness reduction up to 99%, turbidity removal >95%

- Performance Advantages: Extends membrane life, reduces scaling and fouling, improves final water quality

- Applicable Industries: Boiler feedwater treatment, cooling tower make-up water

3. Technology Innovation and Competitive Edge

Manufacturers continually focus on innovation, integrating advanced technologies for enhanced efficiency, sustainability, and cost-effectiveness. Key innovations include:

| Technology | Traditional Systems | Advanced Systems | Benefits |

|---|---|---|---|

| Membrane Material | Cellulose acetate | Thin-film composite (TFC) membranes | Higher permeability, better chlorine resistance |

| Energy Recovery Devices | None | Pressure exchangers, turbochargers | Energy savings up to 40% |

| Automation & Control | Manual operation | Smart sensors and PLC control | Optimized process, minimal downtime |

| Advanced Oxidation Processes (AOPs) | Chlorination | Ozonation combined with UV/H2O2 | Enhanced disinfection, fewer harmful by-products |

In my recent engagement with a Southeast Asian manufacturing facility, upgrading their cooling tower water treatment from chlorine-based dosing to an ozonation system increased biocide efficiency by 30%, reduced chemical consumption by 25%, and minimized corrosion issues, resulting in annual savings exceeding $150,000. This exemplifies how advanced oxidation processes translate into both economic and operational gains.

4. Industry Position and Market Outlook

Emerging markets in Africa, Southeast Asia, South America, and broader Asia show strong demand growth for water treatment systems powered by urbanization and industrialization. These regions prioritize affordable, scalable solutions that comply with international regulations.

Manufacturing hubs in these regions are rapidly adopting standards aligned with global frameworks, including ISO certifications and guidance from authoritative bodies such as the American Water Works Association (AWWA). For instance, the ANSI/AWWA F120 standard recognizes ozonation as a legitimate and effective method for drinking water and wastewater treatment, bolstering confidence in these technologies.

According to recent market analyses, global industrial water treatment equipment markets are forecasted to expand at a compound annual growth rate (CAGR) exceeding 6% through 2030, driven by stricter regulation, rising awareness of water scarcity, and advances in smart manufacturing.

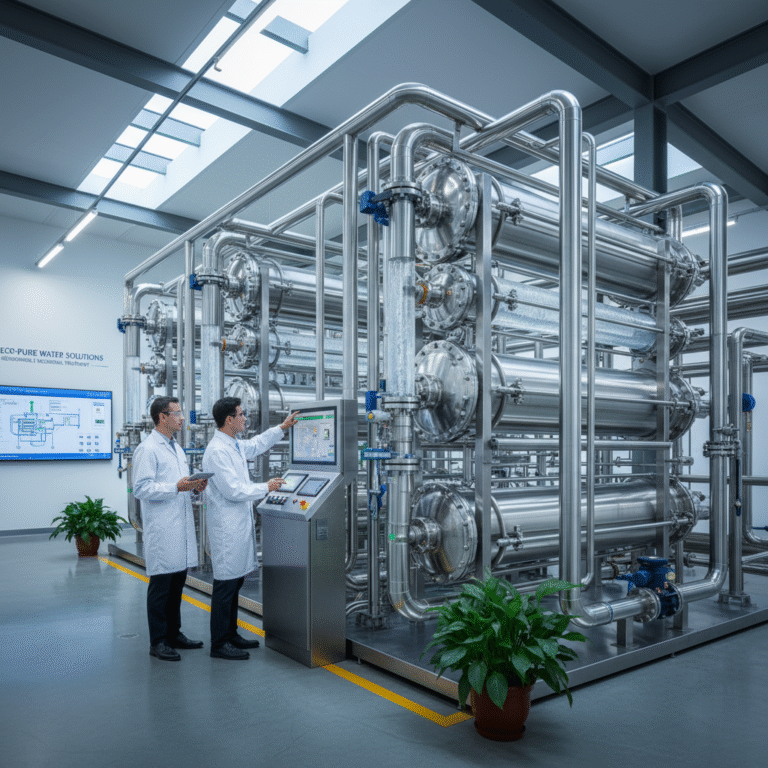

5. Manufacturing and R&D Excellence

Leading equipment manufacturers showcase capabilities through:

- State-of-the-art Production Facilities: Automated machining, precision assembly lines, and comprehensive quality assurance protocols.

- Continuous R&D Investment: Partnerships with universities, pilot project deployment, and iterative prototyping.

- Collaborative Innovation: Joint development with end-users enabling tailored solutions harnessing the latest technological breakthroughs.

For example, a collaborative R&D initiative with a South American chemical plant led to the development of customized ultrafiltration modules capable of handling fouling-prone feedwater, extending membrane lifespan by over 20% compared to previous installations.

6. Client Success Stories and Implementations

Across diverse sectors, OEMs report measurable impacts from advanced water treatment systems:

- Textile Industry: Implementation of dual-stage ultrafiltration combined with ozonation reduced chemical oxygen demand (COD) by 55%, ensuring compliance with discharge permits.

- Food and Beverage: Integration of reverse osmosis and EDI systems resulted in ultrapure water production that improved final product taste consistency, enabling process water reuse and cutting freshwater consumption by 40%.

- Municipal Water: Deploying ozonation systems enhanced pathogen control, notably reducing Cryptosporidium and Giardia contamination, a critical health risk in many developing regions.

These case studies highlight the convergence of technology and practical benefits, reaffirming the importance of tailored, reliable water treatment solutions.

7. Commitment to Environmental Sustainability

Modern water treatment equipment embodies sustainable design principles by:

- Reducing chemical usage through advanced oxidation and membrane filtration.

- Lowering energy consumption via energy recovery devices and advanced control algorithms.

- Minimizing wastewater generation with high recovery ratios (>85%) and recycling capabilities.

- Employing environmentally friendly materials and adhering to circular economy practices in manufacturing.

Such commitments not only support global environmental goals but also enhance clients’ corporate social responsibility (CSR) profiles.

8. Invitation for Collaboration and Consultation

For organizations seeking to optimize their industrial water footprint, customized solutions are available that blend technical sophistication with economic viability. Expert consultation can identify optimal configurations tailored to specific process requirements and regional conditions.

Prospective clients are encouraged to engage through multi-channel contact options, including direct inquiry forms, virtual consultations, and technical workshops. Collaborative partnerships foster continuous improvement and co-innovation, driving shared success in water sustainability.

In summary, the industrial water treatment landscape is dynamically advancing, powered by innovative equipment that delivers superior performance, regulatory compliance, and environmental benefits. Stakeholders across emerging markets stand to gain by leveraging these technologies to ensure sustainable and efficient water use for decades to come.

References

- Grand View Research – Ozone Generators Market Size, Share | Industry Report, 2033

- ANSI Webstore – ANSI/AWWA F120: Ozone Systems for Water

- Persistence Market Research – Ozone Generator Market Size & Leading Players, 2032

- Oxytrading – Industrial Ozone Applications for Water Treatment

- Precedence Research – Ozone Generator Market Size to Surpass USD 2.91 Bn by 2034

- ResearchGate – Ozone for Industrial Wastewater Treatment: Recent Advances and Sector Applications