Curious Perspectives on Water Treatment Plant RO System Performance

In today’s industrial landscape, the demand for clean, purified water has never been more critical. Various sectors—from power generation and pharmaceuticals to food processing—rely heavily on advanced water treatment technologies to ensure process integrity, compliance with environmental regulations, and sustainable operations. Among these technologies, the water treatment plant RO system stands out as a cornerstone solution, transforming raw water into high-purity resource streams essential for industrial use. This article offers a comprehensive exploration into the manufacturing, application, and performance of such systems, tailored specifically for B2B professionals and technical procurement decision-makers.

1. Industry Landscape and Company Expertise

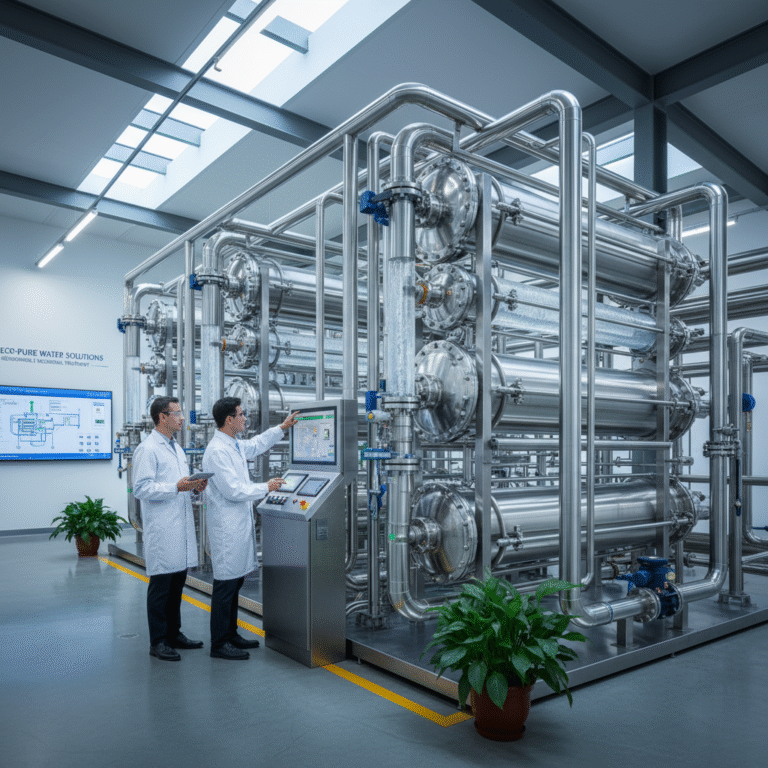

The modern industrial water treatment sector has evolved into a technologically sophisticated field, requiring manufacturers to combine deep R&D capabilities with environmental stewardship. Our hypothetical enterprise represents the archetype of industry leadership with a focus on designing, engineering, and manufacturing state-of-the-art reverse osmosis (RO) systems and associated water purification equipment. Emphasizing innovation, reliability, and ecological responsibility, the company adheres to the highest standards of quality management and environmental compliance.

Understanding the critical role water treatment plays in sustainable industrial growth, this organization invests significantly in continuous process optimization and equipment longevity. These factors contribute not only to operational excellence but also to reducing the industrial water footprint, aligning with global sustainability goals.

2. Comprehensive Product Portfolio: From RO to Advanced Pretreatment

The portfolio encompasses a broad selection of water treatment solutions designed to meet varying industrial demands. Below is a detailed exposition of the key equipment categories and their industrial applications:

2.1 Reverse Osmosis (RO) Systems

At the heart of the portfolio lies the RO systems engineered for both brackish and seawater applications. Utilizing semi-permeable membranes, these systems achieve high salt rejection rates (up to 99.5%), effectively removing dissolved solids, bacteria, and organic contaminants.

- Technical Parameters: Permeate recovery rates range between 75–85%, operating pressures from 6 to 40 bar depending on feed water salinity, and modular designs for capacities spanning 10 m³/h to 500 m³/h.

- Performance Advantages: High energy efficiency membranes, automated cleaning cycles, and integrated monitoring systems ensure minimal downtime and long membrane lifespan.

- Industry Applicability: Power plants require ultrapure water for boilers; chemical manufacturing benefits from contaminant-free process water; pharmaceutical production mandates compliant water quality standards.

2.2 Ultrafiltration (UF) Systems

Complementing the RO units, ultrafiltration membranes provide robust pretreatment by eliminating suspended solids, colloidal particles, and some pathogens, thereby protecting downstream RO membranes and enhancing system longevity.

- Technical Highlights: Pore sizes between 0.01–0.1 microns; flux rates of approximately 100–150 LMH (liters per square meter per hour).

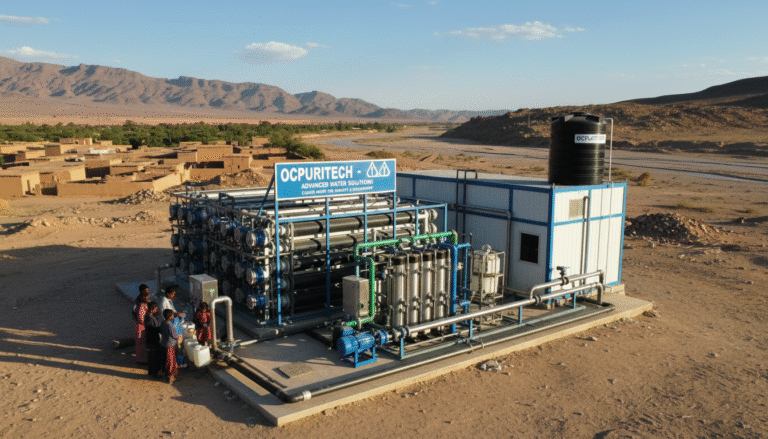

- Applications: Ideal for feedwater pretreatment in high turbidity water sources common in emerging markets such as Southeast Asia and Africa.

2.3 Electrodeionization (EDI) Systems

For industries demanding ultrapure water, such as semiconductor and pharmaceutical manufacturing, EDI systems provide continuous, chemical-free deionization, offering consistent low resistivity water.

- Performance Metrics: Produces water resistivity of up to 18.2 MΩ·cm; operates continuously without chemical regenerants.

- Use Cases: Perfect for polishing RO permeate to achieve final water quality standards compliant with regulatory requirements.

2.4 Pretreatment and Softening Systems

Successful RO operation is contingent upon effective pretreatment to remove hardness ions, chlorine, and particulates that could foul or degrade membranes. The portfolio includes automatic softeners, multi-media filters, activated carbon filters, and chemical dosing systems to optimize feed water quality.

- Key Features: Automated backwashing routines and precise dosing control, modulated by integrated PLC systems.

- Industrial Relevance: Particularly vital in regions with hard water or industrial effluent containing complex contaminants, thereby extending RO membrane life.

3. Technological Innovations and Competitive Edge

Innovation is embedded across all product lines, with a focus on enhancing efficiency and reducing environmental impact. One notable advancement is the integration of energy recovery devices (ERDs) in high-pressure RO units, significantly lowering operational costs.

| Feature | Traditional RO Systems | Advanced RO with ERD |

|---|---|---|

| Energy Consumption (kWh/m³) | 3.5 – 4.5 | 1.5 – 2.5 |

| Water Recovery Rate (%) | 65 – 75 | 75 – 85 |

| Membrane Replacement Frequency | Every 2 – 3 years | Every 3 – 4 years |

| Operational Downtime | 10 – 15% | 5 – 7% |

Besides energy recovery, automation features such as real-time membrane performance monitoring, predictive maintenance alerts, and remote control have been implemented, enhancing reliability and reducing unplanned repairs.

4. Market Position and Industry Trends

The global market for industrial water treatment plant RO systems is poised for robust growth. According to recent market analyses, the industrial water treatment sector is projected to escalate from US$4.5 billion in 2023 to an estimated US$7.8 billion by 2032, at a CAGR of approximately 6.2%. This is primarily driven by increased industrial activities in Asia-Pacific, with parallel expansions in Africa and South America focusing on urbanization and demand for clean water.

The industrial segment currently represents about 43.3% of the entire water treatment systems market in 2024, fueled by sectors such as power, chemical, pharmaceutical, and food processing. Stringent environmental regulations and the need for efficient resource utilization also act as growth catalysts.

The commercial water treatment market segment, including applications in hospitality and healthcare, is expected to grow at an even faster rate of 9.2% CAGR between 2025 and 2033, underscoring the broadening role of RO technology across industries.

These dynamics highlight the strategic importance of selecting technologically advanced, reliable, and scalable RO solutions to meet evolving water quality demands.

5. Manufacturing and R&D Capabilities

The manufacturing facilities utilize modern automated production lines, incorporating precision machining and stringent quality control including ISO 9001:2015 certifications. Continuous process improvement methodologies such as Six Sigma and Lean manufacturing are embedded in operations to ensure defect-free production and optimal resource use.

The R&D team collaborates with academic institutions and industry partners focusing on membrane technology innovations, energy-efficient system designs, and real-time process analytics. Pilot projects validate new membranes and system configurations under diverse industrial feed water conditions, accelerating time-to-market for advancements.

6. Success Stories from Field Applications

Based on personal experience managing industrial projects deploying water treatment plant RO systems, I would like to share two illustrative cases:

- Case 1: Power Generation Plant in Southeast Asia

In a 100 MW coal power station, implementing a multi-stage RO system with integrated EDI produced ultrapure boiler feed water with TDS less than 10 ppm, reducing boiler tube corrosion incidents by 40% and extending maintenance intervals by 30%. Yearly water treatment costs dropped by 15%, primarily due to reduced chemical consumption and improved membrane lifespan. - Case 2: Pharmaceutical Facility in South America

A high-capacity RO system, paired with ultrafiltration pretreatment, ensured consistent compliance with stringent pharmacopeial water standards. The installation improved overall plant throughput by 20%, with minimal process downtime thanks to automated membrane cleaning and real-time diagnostics.

These examples reinforce the importance of adaptive system design tailored to specific industrial contexts and the value of holistic service support post-installation.

7. Commitment to Environmental Sustainability

Given the urgent global imperative to conserve freshwater resources, the company’s product development emphasizes sustainability through energy-efficient designs, minimal chemical usage, and modular systems facilitating easier upgrades instead of replacements.

Wastewater management systems incorporating RO reject stream treatment and reuse options further reduce environmental impact. Green manufacturing practices ensure that production processes maintain low emissions and waste generation.

8. Get in Touch: Tailored Solutions for Your Water Treatment Needs

Understanding that each industrial water treatment challenge is unique, we encourage stakeholders to engage with our technical consultants for a personalized assessment and solution proposal. Multi-channel contact options, including online inquiries, phone consultations, and on-site evaluations, are available to support customers in Africa, Southeast Asia, South America, and Asia.

By leveraging innovative water treatment plant RO system technologies, industries can safeguard their operational resilience while contributing positively to environmental stewardship.

References

- Grand View Research – Water Treatment Systems Market Size | Industry Report, 2033

- Grand View Research – Industrial Reverse Osmosis System Market Report | Global Forecast From 2025 To 2033