Daring Reverse Osmosis Water System Innovations Save Industrial Costs

In today’s industrial and commercial landscapes, water treatment technologies have become indispensable. Among these, reverse osmosis water systems stand out as a transformative solution, offering high-efficiency purification that safeguards process quality and reduces operational expenditures. This article unpacks the core technical components of RO systems, their deployment across diverse scales, and their versatile applications spanning industrial manufacturing to commercial water provisioning.

1. Core Technologies of Reverse Osmosis Water Systems

The fundamental building block of every RO water purification system is the semipermeable membrane that selectively removes dissolved solids, contaminants, and microorganisms from water. Let us explore the pivotal system modules:

1.1 Reverse Osmosis Membrane Systems

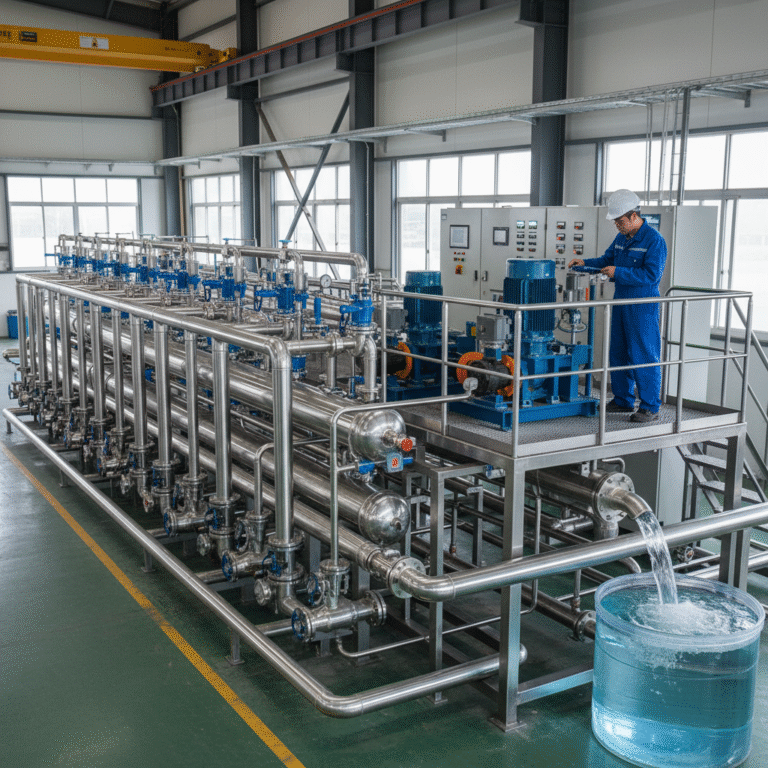

RO membranes operate by leveraging pressure differentials to drive water molecules through tightly woven polymer layers, thus leaving salts and pollutants behind. Typical industrial RO membranes feature product capacities spanning from several hundred liters per hour to tens of thousands, enabling scalability from small commercial setups to large-scale manufacturing plants. Membrane materials are engineered for durability against chemical and mechanical stress, ensuring operational lifespan and consistent purification rates.

1.2 Filtration and Water Softening Units

Pre-treatment modules comprising sediment filters, activated carbon filters, and water softeners are critical to RO system longevity and performance. Water softeners mitigate scaling risks by removing hardness-causing ions like calcium and magnesium. Their integration optimizes membrane efficiency, reduces maintenance costs, and enhances overall water quality for sensitive industrial uses, such as in cooling towers or boiler feedwater systems.

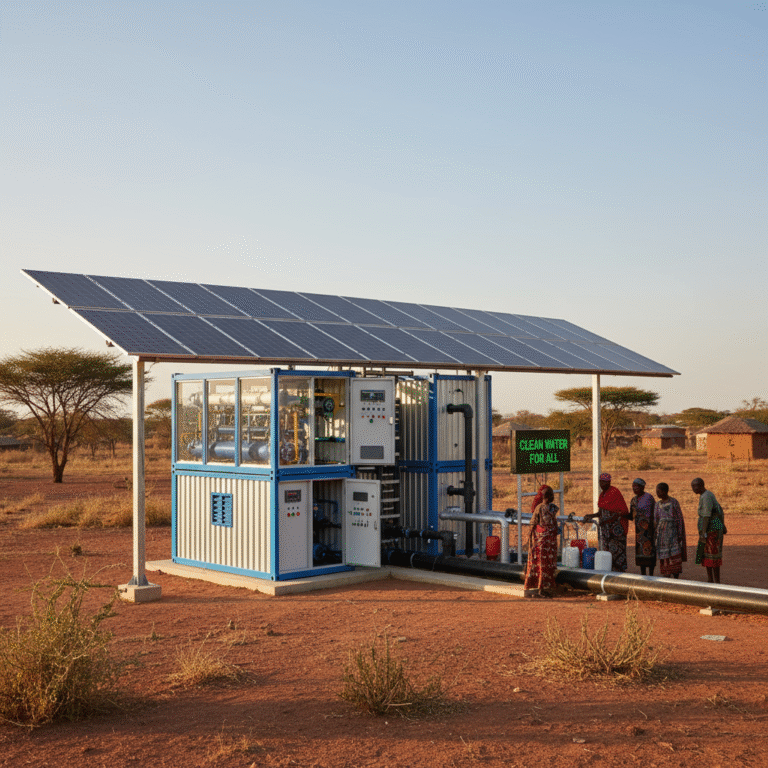

1.3 Containerized and Modular RO Systems

For greater operational flexibility, containerized RO systems encapsulate all equipment — including membranes, pumps, and control panels — within compact, transportable units. These are ideal for remote industrial sites, emergency water supply setups, and modular manufacturing expansions. Such systems typically cover capacity ranges from 5 cubic meters per hour (m³/h) to 100 m³/h, allowing tailored deployment based on process demand.

1.4 UV Sterilization and Cleaning Systems

Ultraviolet (UV) disinfection units complement RO membranes by inactivating residual pathogens, ensuring microbiologically safe outputs. Automated membrane cleaning systems employing chemical dosing prevent fouling and biofilm buildup, maintaining consistent permeate quality. This dual approach extends equipment life while reducing downtime — critical factors in industrial water management.

2. Multi-Scale Equipment Lines to Meet Diverse Industrial Needs

Recognizing the broad spectrum of industrial demands, manufacturers offer multi-tiered product lines:

- Small-Scale Systems: Designed for laboratories, pilot plants, and boutique manufacturing, with typical throughput of up to 1 m³/h.

- Medium-Scale Plants: Suited for commercial kitchens, food and beverage processing, and pharmaceutical sectors, providing 5 to 50 m³/h capacity ranges.

- Large-Scale Industrial Units: Engineered for heavy industries such as petrochemical, power generation, and municipal water treatment, delivering capacities surpassing 100 m³/h.

This stratified approach facilitates cost-effective investment, aligning purification capabilities with operational scale without overcapitalization.

3. Proven Performance and Quality Assurance

Industry-leading RO system manufacturers emphasize stringent quality controls, including ISO-certified processes, advanced membrane fabrication technologies, and meticulous system integration. These measures ensure high recovery rates often exceeding 75%, salt rejection rates above 98%, and robust resistance to variable feed water qualities. Real-time monitoring and smart automation enhance reliability and allow operators to optimize water usage dynamically — a key cost-saving strategy.

4. Diverse Application Scenarios of Industrial RO Systems

The versatility of reverse osmosis water systems extends beyond traditional water treatment plants. Here are representative case applications:

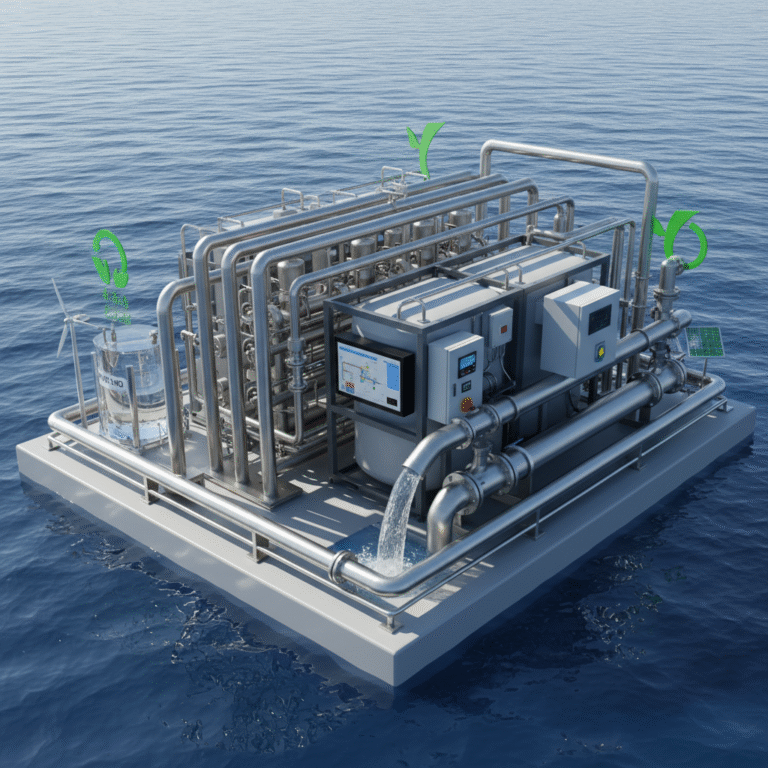

4.1 Seawater Desalination

RO technology is the backbone of many seawater desalination initiatives, providing fresh water to industrial coastal facilities and municipalities. Innovative membrane materials and energy recovery units have markedly reduced energy consumption, turning desalination into a more sustainable practice.

4.2 Portable and Emergency Water Purification

Compact RO units enable rapid deployment in disaster relief zones or remote industrial sites lacking infrastructure. Their ability to remove a broad spectrum of contaminants ensures safe drinking water availability with minimal setup time.

4.3 Space and Specialized Environment Water Systems

Advanced systems akin to the RO principle are implemented in space missions and isolated research stations, where water reuse and ultra-pure supply are vital. Such implementations demonstrate the adaptability of RO technology to stringent quality requirements under extreme conditions.

5. Summary and Strategic Insights

Reflecting on my experience managing industrial water treatment projects across sectors, embracing multifaceted reverse osmosis system innovations has proven instrumental in slashing operational costs and enhancing water quality compliance. Key success factors include precise pre-treatment alignment, scalable membrane modules, and integrating smart disinfection processes.

Indeed, according to authoritative research in 2022, the global water treatment systems market was valued at approximately $35 billion, fueled by growing industrialization and rapid urban expansion, especially in Asia-Pacific regions. This trend underscores the rising demand for effective, reliable water purification mechanisms such as reverse osmosis systems.

Ultimately, selecting an RO system line that aligns operational throughput with evolving water quality challenges leads to sustainable cost savings and environmental benefits, securing business continuity in increasingly resource-constrained environments.

References

- Grand View Research: Water Treatment Systems Industry Growth (2022-2030)