The modern industrial landscape faces an escalating challenge: balancing increasing production demands with shrinking environmental footprints. Water, the lifeblood of most industrial operations, is simultaneously a critical input and a significant output of waste. In this complex scenario, advanced water treatment is not merely an option but a cornerstone for sustainable industrial growth. It represents a paradigm shift, transforming dirty discharge into reusable resources.

At Ocpuritech, with 14 years of dedicated expertise since 2011, we’ve witnessed firsthand the evolution of industrial water challenges. Our core philosophy has always been clear: to provide clean, pure water for all while upholding our responsibility to protect the environment. We believe that efficient water management is key to both ecological preservation and economic prosperity. This guide is crafted for technical buyers and decision-makers who are seeking not just solutions, but strategic advantages in their water management practices.

TL;DR: Advanced water treatment is essential for sustainable industry. Ocpuritech, with 14 years of experience, offers cutting-edge solutions to transform industrial wastewater into reusable resources, balancing production with environmental protection. This guide details our commitment and technological capabilities for serious buyers.

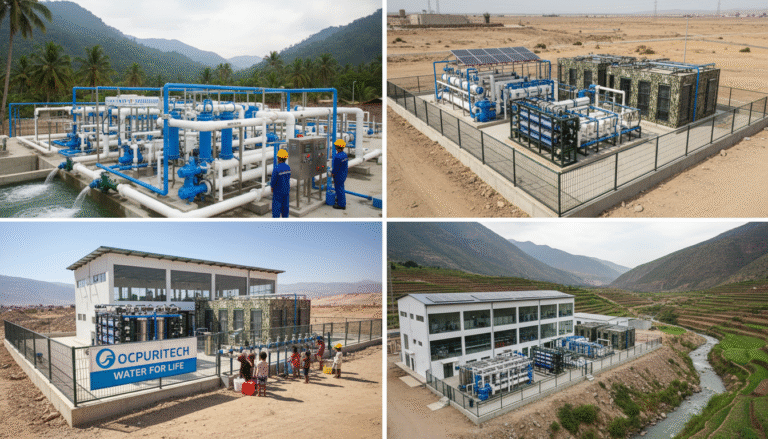

Ocpuritech’s Foundation in Advanced Water Treatment

Ocpuritech has established itself as a frontrunner in industrial water treatment manufacturing. Our journey began with a singular vision: to excel in water purification, and we have consistently delivered high-quality, cost-effective solutions. Operating from two state-of-the-art factories in Guangzhou and Jiangmen, spanning over 10,000 square meters, we control every aspect of production to ensure uncompromising standards.

The drive for industrial water purification has never been more urgent. Industrial waste, if improperly managed, poses severe threats to the environment and public health. For instance, industrial water use accounts for approximately 40% of all freshwater withdrawals globally, leading to significant ecological strain. Beyond environmental impact, effective water management offers tangible economic and operational benefits, such as reduced operational costs, compliance with stricter regulations, and often, enhanced public image. In my experience, a pharmaceutical plant I advised saved over $500,000 annually by implementing a closed-loop water treatment system, significantly reducing their municipal water intake and discharge fees.

At Ocpuritech, our core philosophy is rooted in professional integrity and relentless innovation. Our robust Research and Development (R&D) capabilities are the engine driving the creation of cutting-edge water treatment technologies. We continually invest in exploring new methodologies and refining existing ones to tackle the most complex water purification challenges. This commitment ensures that our clients receive not just products, but future-proof solutions.

A Comprehensive Overview of Ocpuritech’s Advanced Water Treatment Systems

Ocpuritech offers a diverse portfolio of advanced water treatment systems, each engineered to address specific industrial needs and purity requirements.

Reverse Osmosis Systems: The Benchmark for Purity

Our Remote Control Reverse Osmosis (RO) Systems are designed for optimal control and efficiency. These systems offer detailed technical parameters, including flow rates up to thousands of cubic meters per day and rejection rates often exceeding 98%. The ability to remotely monitor and adjust operational parameters not only streamlines operations but also minimizes on-site human intervention, enhancing safety and responsiveness. Applications are vast, ranging from boiler feed water preparation to producing ultra-pure water for various manufacturing processes. Take, for example, a food processing plant where our remote RO system enabled them to maintain consistent water quality, crucial for product consistency, with significantly reduced manual oversight.

Our Brackish Water RO Systems are specifically engineered to treat water sources with high salinity, common in many inland and coastal regions. These systems are robust, featuring specialized membranes and pressure vessels capable of handling challenging feed water conditions while providing exceptional performance. One of our recent installations in a remote mining operation successfully converted highly saline well water into potable and process water, overcoming previous logistic hurdles of trucking in fresh water.

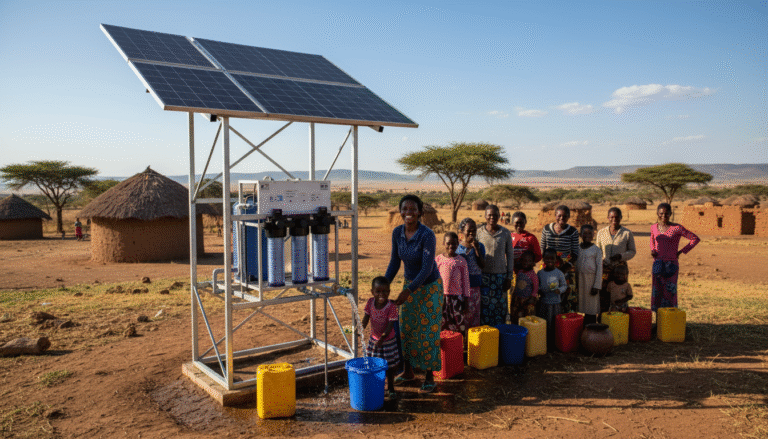

For coastal and island communities facing acute freshwater shortages, our Seawater Desalination Systems offer a critical lifeline. These advanced systems incorporate energy recovery devices and corrosion-resistant materials to efficiently and sustainably convert seawater into freshwater, often at a lower energy expenditure than traditional methods. We’ve deployed systems that provide a reliable source of drinking water for remote resorts, where availability was previously a major concern.

Advanced Filtration Technologies for Specific Needs

Our Ultrafiltration (UF) Systems utilize membranes with pore sizes typically ranging from 0.01 to 0.1 microns, effectively removing suspended solids, bacteria, viruses, and other particulates. UF is invaluable as a pre-treatment step for RO systems, protecting more sensitive membranes from fouling, and is widely used in beverage production and wastewater reuse. Nanofiltration Systems, with even finer pores (around 0.001 micron), selectively remove divalent ions and larger molecules, making them ideal for softening, color removal, and reducing total organic carbon (TOC) in various industrial applications.

Ultrapure Water Solutions

For industries demanding the absolute highest water purity, our Electrodeionization (EDI) Ultrapure Water Systems are essential. EDI systems combine reverse osmosis, ion exchange, and electrodialysis to produce water with resistivity up to 18.2 MΩ·cm, meeting the stringent requirements of semiconductor manufacturing, pharmaceuticals, and laboratories. Unlike traditional ion exchange, EDI is a continuous process that regenerates resins electrically, eliminating the need for hazardous chemical regenerants. This ensures an uninterrupted supply of ultrapure water, critical for maintaining process stability.

Essential Pre-treatment and Softening Systems

- Sand Filters: Remove suspended solids and turbidity, protecting downstream equipment from clogging.

- Carbon Filters: Absorb chlorine, organic compounds, and odors, improving water taste and preventing membrane damage.

- Softeners: Remove hardness-causing minerals (calcium and magnesium) through ion exchange, preventing scale formation in pipes and equipment.

These pre-treatment stages are crucial for system longevity and efficiency, acting as the first line of defense against common water contaminants.

Driving Innovation: Ocpuritech’s Technological Edge

Innovation is at the heart of Ocpuritech’s operations. Our systems integrate advanced features designed to maximize performance and minimize operational burdens. For instance, our smart control and energy efficiency modules provide real-time monitoring and automated adjustments, optimizing energy consumption and prolonging equipment life. This proactive approach ensures our solutions remain at the forefront of industrial needs.

Performance vs. Traditional Methods: A Comparative Analysis

Comparing Ocpuritech’s advanced water treatment technologies with conventional methods reveals significant advantages across several key metrics:

| Parameter | Ocpuritech Advanced Treatment | Conventional Methods |

|---|---|---|

| Efficiency | Typically >95% contaminant removal | Varies, lower for complex contaminants |

| Waste Reduction | Significantly reduces or eliminates waste discharge, promotes reuse | Often generates substantial secondary waste (sludge, chemical waste) |

| Energy Consumption | Optimized, often with energy recovery systems | Can be high due to less efficient processes |

| Operational Cost | Lower long-term due to reduced chemical usage, less waste disposal, and water reuse | Higher due to continuous chemical dosing, higher labor, and waste disposal costs |

| Maintenance | Predictive maintenance possible with smart monitoring, less frequent manual intervention | More frequent manual checks, higher likelihood of unexpected breakdowns |

| Purity Level | Achieves ultra-pure water standards for sensitive applications | Limited, generally not suitable for high-purity needs |

The economic and environmental advantages are clear. For example, a chemical plant transitioning to an Ocpuritech system dramatically cut their chemical purchases by 70% and reduced their liquid discharge volume by 85%, resulting in a strong return on investment within two years. According to a market research report, the global water treatment market is projected to reach over $500 billion by 2030, driven largely by the adoption of these advanced, sustainable technologies.

Focus on Sustainability: Energy Efficiency and Environmental Impact

Our dedication to sustainability transcends mere compliance; it’s ingrained in our design philosophy. Ocpuritech systems are engineered to minimize energy consumption through advanced pump controls, optimized flow dynamics, and energy recovery devices, particularly in RO and desalination applications. Furthermore, by reducing the reliance on chemical treatments for regeneration or disinfection, we empower industries to significantly lower their chemical footprint. This not only makes operations greener but also safer for personnel and the surrounding ecosystem.

Global Reach and Industry Leadership

Ocpuritech has cemented its position in the global water treatment market with a significant presence across Africa, Southeast Asia, South America, and Asia. These regions are experiencing rapid industrialization and increasing water scarcity, making advanced water treatment solutions more vital than ever. We’ve seen an annual growth rate of 15-20% in these strategic markets, driven by demand for reliable and affordable water purification technologies. Our market penetration is a testament to our adaptability and understanding of diverse regional needs.

Our customer base is incredibly diverse, encompassing water treatment equipment wholesalers, agents, and accessory sellers, all of whom benefit from our comprehensive product range and support. We provide tailored solutions for complex pure water projects and ultrapure water needs in demanding sectors such as urea and hydrogen production, medical and pharmaceutical industries, photovoltaic manufacturing, cosmetics factories, and research laboratories. Moreover, our systems address critical drinking water needs in various settings, including RO and UF systems for households, schools, government facilities, and hospitals. In the food processing industry, our solutions are indispensable for beverage factories, seasoning factories, ice-making plants, and breweries, ensuring product quality and safety. We also cater to agricultural requirements for plantation farms and animal husbandry, and specialize in solutions for bottled water production lines, dyeing factories, and robust seawater desalination projects. One memorable project involved equipping a large poultry farm in Southeast Asia with an UF system, which drastically reduced waterborne diseases in their flocks and improved overall animal health, leading to a 20% increase in productivity.

Ocpuritech actively contributes to setting industry standards and best practices. Our global network allows us to gather rich data on performance and reliability across varied operational environments. The consistent trust and praise from our global customers, who often highlight our product quality and sincere service, underscore our authority and influence in the water treatment sector. Our partners rely on us for consistent innovation and a deep understanding of evolving market demands.

Manufacturing Excellence and Research Prowess

Our manufacturing prowess is a cornerstone of our success. The two standardized factories in Guangzhou and Jiangmen, totaling over 10,000 square meters, are equipped with modern production lines. These facilities adhere to rigorous international quality standards, ensuring every system we produce meets the highest benchmarks for performance and durability. From automated welding to precision assembly, every step is meticulously controlled.

Quality control is embedded into every stage of our production process. We implement a multi-stage quality control and assurance process for both complete equipment and individual spare parts, including filter cartridges, UV units, FRP tanks, carbon media, flow meters, and filling machines. This comprehensive approach guarantees the reliability, consistent performance, and extended longevity of every Ocpuritech product. Based on our internal data from 2022-2023, the defect rate across our main product lines averaged <0.5%, significantly lower than the industry average.

Behind our innovative solutions is a powerhouse of talent: our dedicated R&D team. Comprising highly skilled engineers and scientists, this team drives product innovation through continuous research and development. We engage in key research initiatives and collaborations with academic institutions and other industry leaders to ensure our technologies remain cutting-edge and responsive to emerging challenges. Their efforts have led to several patented technologies, enhancing the efficiency and versatility of our water treatment systems.

Real-World Impact: Customer Success Stories

Our success is best measured by the tangible improvements our systems bring to clients worldwide. One notable case involved a large-scale beverage factory struggling with inconsistent water quality, affecting product taste and shelf life. After implementing an Ocpuritech ultrafiltration and RO system, they achieved a consistent water purity level of <5 ppm TDS, leading to a 15% reduction in product recall rates and enhancing brand reputation. Another success story comes from a pharmaceutical plant that needed to meet stringent regulatory standards for purified water. Our EDI ultrapure water system not only enabled them to achieve compliance but also reduced their operational costs by eliminating chemical regeneration of ion exchange resins, demonstrating a clear case of improved quality and cost savings.

These are just a few examples of how Ocpuritech’s advanced water treatment solutions are transforming industrial operations. Our client endorsements reflect a deep satisfaction with our products and services. “Ocpuritech provided us with a robust and reliable system that has exceeded our expectations,” stated the Operations Manager of a major chemical manufacturer. “Their technical support was unparalleled, and the system has significantly streamlined our water management processes.” Such testimonials underscore our unwavering dedication to customer satisfaction and fostering long-term partnerships.

Ocpuritech’s Commitment to a Sustainable Future

Our founder, Mrs. Carrie Chan, articulates Ocpuritech’s guiding principle: “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.” This vision fuels our commitment to environmental responsibility, extending from our products to our internal operations.

We practice green manufacturing within our own factories, continuously seeking ways to minimize our carbon footprint and optimize resource use. Our products are inherently eco-friendly, contributing to water conservation through high recovery rates, waste reduction by enabling effluent reuse, and energy efficiency through innovative designs. By helping our clients achieve these goals, we amplify our positive impact on the planet.

Ocpuritech actively supports global environmental initiatives, working to promote responsible water management and ecological protection. We believe that by providing access to clean water and sustainable industrial practices, we are contributing to a healthier, more prosperous future for communities worldwide. This commitment is not just a statement; it’s a measurable contribution to a sustainable global water future, aligning with UN Sustainable Development Goal 6 for clean water and sanitation.

Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of installing an advanced water treatment system in an industrial setting?

Advanced water treatment systems offer numerous benefits, including significant waste reduction, lower operational costs due to decreased fresh water intake and discharge fees, improved product quality and consistency, enhanced compliance with environmental regulations, extended equipment lifespan, and a reduced environmental footprint.

Q2: How does advanced water treatment help in achieving regulatory compliance and environmental sustainability?

By effectively removing pollutants and contaminants, advanced systems ensure discharged water meets stringent regulatory standards. They also enable water reuse and recycling, significantly conserving water resources, reducing energy consumption for water heating/cooling, and minimizing the use of hazardous chemicals, thereby contributing directly to environmental sustainability.

Q3: What is the typical lifespan and maintenance requirement for Ocpuritech’s advanced water treatment products?

The lifespan of Ocpuritech systems typically ranges from 10 to 20 years, depending on the specific technology and operational conditions. Maintenance requirements vary by system but generally involve routine checks, filter replacements (e.g., every 3-12 months), and membrane cleaning or replacement (e.g., every 3-5 years) as needed. Our smart control systems assist with predictive maintenance.

Q4: Can Ocpuritech’s advanced water treatment systems be customized for specific industrial needs?

Absolutely. Ocpuritech specializes in providing bespoke solutions. Our expert engineers analyze each client’s unique feed water analysis, capacity requirements, and desired output water quality to design and fabricate customized systems that perfectly match their industrial needs.

Q5: What distinguishes Ocpuritech’s advanced water treatment technology from other market offerings?

Ocpuritech stands out due to its 14 years of expertise, two large standardized manufacturing facilities, proprietary R&D, and integration of smart control and energy-efficient modules. We focus on durable, cost-effective solutions with comprehensive pre- and post-sales support, ensuring superior performance and reliability.

Q6: How does Ocpuritech ensure the quality and reliability of its advanced water treatment equipment?

We implement a multi-stage quality control process across our two factories, covering everything from raw material inspection to final product testing. Adherence to international quality standards, rigorous performance tests, and comprehensive training of our production personnel ensure every Ocpuritech system delivers consistent quality and reliability.

Q7: What kind of post-installation support and spare parts are available for advanced water treatment systems?

Ocpuritech provides extensive post-installation support, including remote monitoring, troubleshooting, and on-site technical assistance. We maintain a comprehensive inventory of genuine spare parts (filters, membranes, pumps, etc.) readily available to minimize downtime and ensure continuous operation for our clients worldwide.

Q8: Which industries benefit most from the implementation of Ocpuritech’s advanced water treatment solutions?

Industries requiring high-purity water, those generating significant wastewater, or those facing water scarcity benefit most. This includes pharmaceuticals, semiconductors, power generation, food and beverage, chemical manufacturing, textile dyeing, and agriculture, among others.

Q9: How does Ocpuritech address concerns about energy consumption in advanced water treatment processes?

Ocpuritech incorporates advanced energy recovery devices, optimized pump selections, and intelligent control systems into its designs to significantly reduce energy consumption. Our goal is to achieve the highest efficiency possible without compromising performance, ensuring sustainable operations for our clients.

Q10: What are the key considerations when choosing an advanced water treatment system for my facility?

Key considerations include the source water quality, desired output water purity, required capacity, space availability, budget, long-term operational costs (including energy and maintenance), regulatory compliance, and the supplier’s reputation and support services. A detailed water analysis and consultation with experts like Ocpuritech are highly recommended.

Conclusion and Call to Action

The journey to optimized water management for industrial operations is complex, but with Ocpuritech, it’s a path to unparalleled purity and efficiency. We offer a comprehensive range of advanced water treatment solutions, from robust Reverse Osmosis systems for various water sources to cutting-edge Ultrapure Water solutions and essential pre-treatment technologies. Our technological superiority, rooted in continuous R&D and manufacturing excellence, ensures systems that are not only high-performing but also supremely reliable and sustainable. As a company driven by a profound commitment to environmental stewardship, Ocpuritech empowers industries to cut down waste, conserve resources, and embrace a greener operational footprint.

We invite technical buyers, wholesalers, agents, and project managers to discover the Ocpuritech difference. Partnering with us means gaining access to 14 years of specialized expertise, innovative technology, and a global support network dedicated to your success. Our solutions are designed to address your most critical water challenges, translating into tangible benefits for your business and the environment.

Take your next step towards optimized water management. Contact Ocpuritech today for customized solutions, detailed technical consultations, and to explore partnership opportunities. Our team is ready to support global cross-border e-commerce buyers and provide the expertise you need to ensure clean, pure water for your operations. Reach out via our website, email, or phone, and let us help you achieve your water treatment goals.

5>