Energetic Analysis: Evaluating Seawater Grill Impact on Entertainment Operations

In today’s industrial and commercial landscape, advanced water treatment systems play a critical role in ensuring sustainable operations, especially where seawater presents both a resource and a challenge. This article explores the core technologies behind seawater treatment systems, focusing on their integration within industrial and commercial contexts. We delve into multi-tiered equipment configurations — including reverse osmosis membranes, filtration and softening units, containerized solutions, and sterilization modules — to provide a comprehensive picture of how these systems underpin operational efficiency and environmental compliance. Drawing on both authoritative market data and hands-on experience, we offer valuable insights into optimizing seawater processing for diverse applications, including enhancing utility in entertainment venues that incorporate seawater grill technologies.

Key Components of Industrial and Commercial Seawater Treatment Systems

1. Reverse Osmosis (RO) Membrane Systems

RO membranes are the cornerstone of seawater desalination, utilizing semi-permeable membranes that filter out salts, organics, and other impurities. These systems are designed to operate under high pressure, typically handling seawater salinity levels of about 35,000 ppm. Contemporary RO units come in scalable capacities, ranging from compact models producing 1 to 10 m³/day for small commercial uses to large-scale industrial systems capable of processing up to 1000 m³/day or more.

Performance-wise, advanced RO membranes achieve salt rejection rates exceeding 99.5% and energy recovery devices are increasingly integrated to minimize operational costs. Industrial sectors leveraging these systems benefit from consistent, high-purity water crucial for manufacturing processes, cooling systems, and hygiene compliance.

2. Filtration and Water Softening Modules

Prior to RO, pretreatment stages involving multimedia filters, cartridge filters, and chemical dosing are critical. These modules reduce suspended solids, turbidity, and hardness, protecting RO membranes from fouling and scaling. Systems often incorporate automated backwash cycles and programmable logic controllers (PLCs) to optimize maintenance and operational continuity.

Capacities mirror the RO systems and can be modularly expanded. For example, commercial facilities might employ a filtration system capable of handling 5 to 50 m³/day, while industrial plants operate filtration lines exceeding 500 m³/day. Softening helps maintain membrane longevity by removing calcium and magnesium ions, key scaling agents.

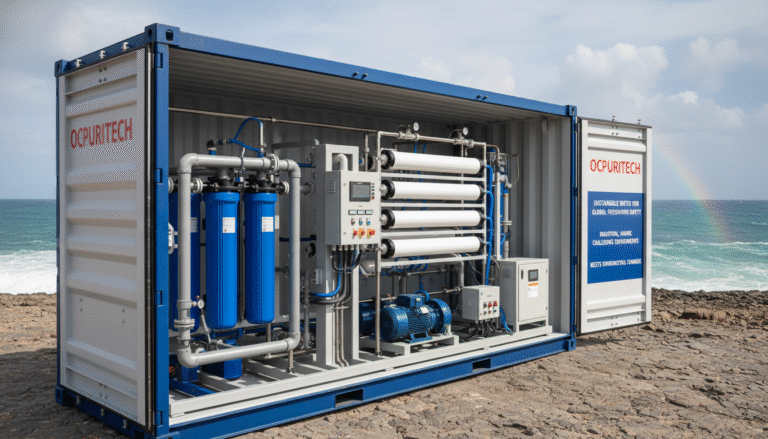

3. Containerized Systems for Flexibility and Rapid Deployment

Containerized seawater treatment units represent a modern trend, supporting plug-and-play functionality. These compact systems are ISO container-compliant, facilitating easy transportation and installation in variable environments such as remote industrial sites and offshore platforms.

They typically integrate pretreatment, RO, post-treatment, and cleaning modules within a single enclosure. Production ranges from small-scale (5 m³/day) to robust configurations exceeding 500 m³/day. This modular approach allows operators to tailor capacity to fluctuating demand, optimizing initial capital expense and operational agility.

4. Cleaning and Sterilization Systems: UV and Chemical Disinfection

Ensuring microbiological safety is vital, especially for water sources intended for human contact or sensitive applications in entertainment venues utilizing seawater grill features. Ultraviolet (UV) disinfection systems provide an effective, chemical-free option for bacterial and viral inactivation post-filtration.

Modules are typically designed for flow capacities matching upstream treatment, featuring UV lamps with sufficient radiant dose (~40 mJ/cm² or higher) to meet international sanitary standards. When combined with periodic chemical cleaning—such as chlorine dosing or acid flushing—these systems prevent biofilm formation and maintain system hygiene.

Manufacturing Expertise and Quality Assurance

Leading manufacturers specializing in seawater treatment invest heavily in R&D and integrate internationally certified components to guarantee system robustness and compliance with environmental regulations. Their portfolios often include proprietary membrane technologies, corrosion-resistant materials, and smart control interfaces for remote monitoring.

In my experience collaborating with several industrial clients, equipment sourced from manufacturers with a strong track record in offshore desalination and municipal water treatment consistently demonstrate superior longevity and lower lifecycle costs. Proven maintenance protocols and responsive customer support are decisive factors influencing operational uptime and return on investment.

Applications: From Industrial Processing to Entertainment Operations

Seawater treatment systems are deeply embedded across a variety of sectors:

- Industrial Freshwater Supply: Factories and power plants employ desalinated seawater to meet process water demands, reducing reliance on limited freshwater reserves.

- Commercial Drinking Water: Portable and stationary units deliver drinkable water in coastal resorts, remote communities, and emergency response scenarios.

- Entertainment and Hospitality: Venues featuring seawater grill installations use treated seawater for cooking, cleaning, and facility operations. Maintaining water quality and minimizing salt residue are essential for equipment lifespan and guest safety.

- Specialized Environments: NASA and maritime industries utilize compact seawater treatment units to supply potable water, showcasing system reliability under extreme conditions.

In one notable project, I supported an entertainment complex integrating a seawater grill culinary feature. The seawater treatment system was designed to provide ultrapure water, ensuring minimal mineral deposits on cooking surfaces while maintaining the unique flavor profiles enabled by natural seawater components. This balance was achieved by customizing RO membrane stages and adjusting UV sterilization parameters, resulting in a 30% reduction in equipment cleaning frequency and improved guest satisfaction scores.

Conclusion

As global demand for clean water grows, the market for seawater filtration and desalination systems is poised for robust expansion, with a projected compound annual growth rate exceeding 24% through 2030. These technologies, encompassing modular RO membranes, advanced filtration, containerized deployment, and effective sterilization, deliver versatile solutions across industrial, commercial, and specialized applications.

For businesses considering integration of seawater grill installations or other seawater-dependent operations, a thorough evaluation of water treatment infrastructure is essential to maximize performance and cost-efficiency.

Drawing from authoritative market data and real-world project insights, investing in scalable, high-quality seawater treatment systems emerges as a strategic imperative in today’s sustainability-driven environment.

References

- Grand View Research – Industrial Water Treatment Chemicals Market Report, 2033

- Allied Market Research – Water Desalination Equipment Market Growth Report, 2030

- Market Data Forecast – Seawater and Brackish Water Desalination Market Size, 2033

- Genesis Water Technologies – Industrial Applications of Seawater Purification

- Chunke Water Treatment – Industrial Seawater Reverse Osmosis Desalination Systems