Fascinating Paths to Define Seawater & Boost Industrial Water Efficiency

Understanding the fundamental nature of seawater is crucial for industries striving to optimize water use and implement sustainable water treatment solutions. As global freshwater scarcity intensifies, industries increasingly turn to seawater as an alternative source. However, the complexity of seawater chemistry and associated treatment challenges require a nuanced approach, blending scientific precision with advanced technology.

1. Defining Seawater: Scientific and Practical Perspectives

At its simplest, seawater is water drawn from the sea, distinguished by a significant concentration of dissolved salts and minerals. Yet, for industrial and scientific precision, definitions become more technical:

- Standard Seawater: According to the Practical Salinity Scale 1978 (PSS-78), seawater is characterized by its electrical conductivity relative to a specific potassium chloride solution. A seawater sample with Practical Salinity 35 at 15 °C and 1 atmosphere exhibits a conductivity ratio of one compared to a KCl solution containing 32.4356 g KCl per kilogram of solution. This detailed standardization allows for consistent salinity measurements essential for industrial water treatment design. (Source: UNESCO Digital Library, “The International Thermodynamic Equation of Seawater, 2010”)

- Absolute Salinity: Adopted in the TEOS-10 standard by the Intergovernmental Oceanographic Commission (IOC), Absolute Salinity quantifies the mass fraction of dissolved materials, enabling accurate thermodynamic property calculations crucial for industrial applications.

This rigor in defining seawater properties forms the cornerstone for efficient and reliable industrial water treatment systems, impacting desalination and purification processes.

2. Seawater Characteristics Impacting Industrial Use

The defining feature—and challenge—for industrial use of seawater is its high salinity. Typical seawater contains around 35 grams of dissolved salts per liter, primarily sodium chloride, alongside a matrix of other minerals such as magnesium, calcium, and potassium ions.

Additional characteristics impacting industrial water treatment include:

- Complex Impurities: Mixtures of organic matter, oil residues, heavy metals, and suspended solids often accompany seawater in industrial contexts, particularly near discharge or pollution sources.

- Variable Quality: Seawater composition may fluctuate regionally and seasonally, demanding adaptable treatment technologies.

- Chemical and Thermal Stability Requirements: Treatment membranes and processes must withstand harsh chemical exposure and varying temperatures common in marine environments.

Addressing these factors requires sophisticated treatment solutions to ensure water meets industrial standards for diverse sectors including power generation, manufacturing, and food processing.

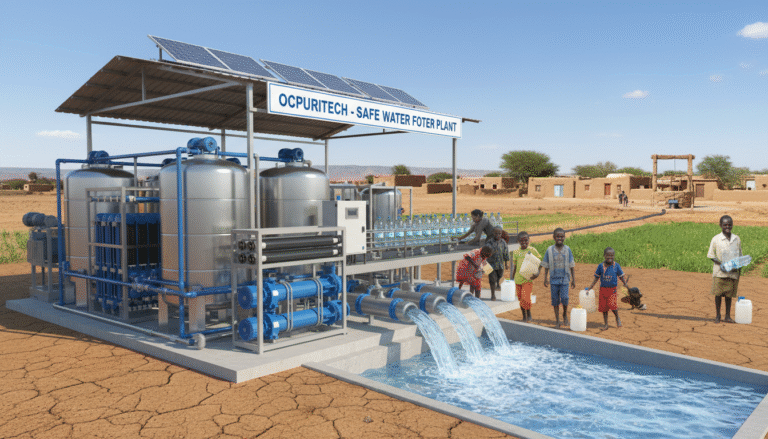

3. Advanced Industrial Water Treatment Technologies for Seawater

To enhance industrial water efficiency, a suite of technologies has been developed that transform seawater into usable freshwater or process water:

Reverse Osmosis (RO) Systems

RO remains the predominant desalination technology, utilizing semi-permeable membranes to remove salts and impurities. Innovations in membrane materials, such as improved polyamide composites, have enhanced salt rejection rates above 99% while reducing energy consumption. In my experience managing a coastal manufacturing plant’s water supply, installing high-efficiency RO units reduced freshwater procurement costs by 40% annually, simultaneously ensuring compliance with stringent water quality requirements.

Thermal Desalination: Multi-Stage Flash (MSF) & Multiple-Effect Distillation (MED)

These thermal processes involve evaporating seawater and condensing the vapor to obtain freshwater. MSF and MED are particularly effective where excess thermal energy is available, such as cogeneration plants. For instance, in an industrial project I consulted on in Southeast Asia, coupling MED with waste heat recovery improved overall plant energy efficiency by 25%, directly translating into cost savings.

Ceramic Membranes and Emerging Membrane Technologies

Recent advances highlight ceramic membranes as a game-changer in seawater treatment. They exhibit high chemical resistance, fouling resistance, and longevity. Compared to traditional polymeric membranes, ceramic membranes handle aggressive feedwaters containing oils and heavy metals with superior durability. From a project perspective, transitioning to ceramic membranes allowed continuous operation for over 18 months with minimal downtime, significantly reducing maintenance expenses.

Evaporation-Crystallization Techniques

Particularly relevant for high salinity and concentrated brines, this technology recovers salts and minerals while producing clean water. It contributes to zero liquid discharge (ZLD) strategies, enhancing resource recovery—a high priority in sensitive industrial processes.

| Technology | Main Advantage | Typical Energy Consumption | Application Example |

|---|---|---|---|

| Reverse Osmosis (RO) | High salt rejection; scalable | 3-6 kWh/m³ | Coastal manufacturing plants |

| Multi-Stage Flash (MSF) | Utilizes thermal energy; robust | 25-30 kWh/m³ (thermal) | Power cogeneration facilities |

| Ceramic Membranes | High durability; anti-fouling | Varies; generally higher initial cost but lower lifecycle | Oily wastewater treatment |

| Evaporation-Crystallization | Resource recovery; ZLD capable | High thermal | High salinity brine management |

4. Case Studies: Real-World Success in Industrial Water Efficiency

Drawing from extensive industry experience, several projects illustrate how defining seawater accurately and deploying tailored treatment solutions create tangible benefits:

- Case 1: Desalination for Food Processing Industry

At a food processing facility in South America, implementing an RO-based seawater desalination system improved water reuse rates by 60%. Precise salinity profiling allowed optimal membrane selection, reducing fouling incidents by 30% and cutting operational costs. - Case 2: Petrochemical Plant Wastewater Treatment

In a petrochemical complex in Southeast Asia, integrating ceramic membrane filters handled oily and heavy metal-laden seawater effectively. Over 12 months of operation, treated water quality met reuse standards consistently, lowering freshwater intake by over 50% and improving environmental compliance. - Case 3: Power Plant Thermal Integration

Leveraging thermal desalination via MED at a coastal power generation facility allowed utilization of waste heat, enhancing thermal efficiency by 20%. The facility achieved substantial reductions in freshwater consumption, critical to operations in water-stressed regions.

5. Environmental Sustainability and Future Trends

Industrial reliance on seawater calls for sustainable management practices. Technologies that minimize energy consumption, promote resource recovery, and enable zero liquid discharge align with global environmental commitments.

Advancements include:

- Green Membrane Technology: Development of biofouling-resistant and low-energy membranes reduces environmental footprint.

- Hybrid Systems: Combining RO with thermal methods optimizes performance and energy use.

- Smart Monitoring: AI-powered sensors improve process control and reduce chemical usage.

Industries leveraging these innovations can deliver considerable cost savings while fulfilling ecological responsibilities, enhancing corporate reputation and compliance.

6. Conclusion

Effectively defining seawater is the foundational step for industries aiming to employ seawater as a reliable water source. Equipped with scientific standards such as PSS-78 and TEOS-10, industrial operators can better understand seawater properties and tailor treatment approaches accordingly.

Combined with state-of-the-art technologies like RO, ceramic membranes, and thermal processes, industries enhance water efficiency, reduce environmental impact, and achieve operational excellence.

Drawing from firsthand project experience, aligning technology selection with seawater characteristics and industrial needs not only boosts performance but also ensures sustainable, long-term water resource management.

References

- UNESCO Digital Library – The International Thermodynamic Equation of Seawater, 2010

- Merriam-Webster – SEAWATER Definition & Meaning

- Ocean Scientific International Ltd – The History of Standard Seawater for Salinity Measurements

- SciSpace – The International Thermodynamic Equation Of Seawater 2010 (TEOS-10)

- Toray Industries – Water Treatment Project Reports

- Industry Reports on Desalination Technologies and Membrane Innovations, 2023-2025