In the modern industrial landscape, the role of reliable and efficient water treatment plant machinery suppliers is paramount. As businesses and municipalities worldwide confront escalating water quality challenges and stringent environmental mandates, the demand for advanced water treatment solutions has surged. This article delves into the critical facets of industrial water treatment machinery manufacturing and application, drawing insights from authoritative data sources alongside hands-on industry experience. The focus encompasses technical innovations, competitive advantages, market positioning, sustainability commitments, and strategic growth outlooks, particularly addressing key regions such as Africa, Southeast Asia, South America, and Asia.

Company and Industry Background: Building Foundations for Water Quality Excellence

Industrial water treatment machinery manufacturers specialize in fabricating equipment that purifies, conditions, and reclaims water used across manufacturing, power generation, chemical processing, and municipal facilities. These companies pioneer technologies that align with core environmental stewardship principles, adhering to global regulations and sustainability goals to minimize ecological footprints.

Recognizing water as a vital resource, these organizations embed robust research and development programs that prioritize innovation in process efficiency and energy conservation. Their mission often stresses the convergence of operational excellence with environmental responsibility, fostering technologies that reduce waste, optimize resource use, and improve water reuse rates.

Product Series Overview: Diverse Technologies Tailored for Industrial Applications

Water treatment systems supplied by these manufacturers can be broadly classified into several key categories, each designed to address specific water quality challenges:

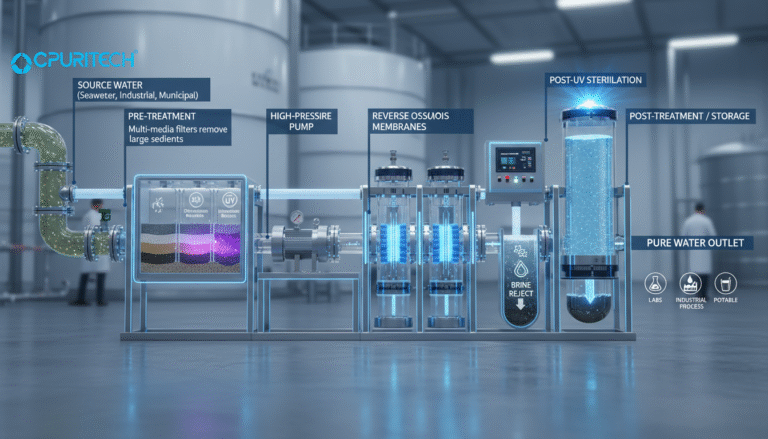

1. Reverse Osmosis (RO) Systems

RO units are central to removing dissolved salts, organic molecules, and microbial contaminants through high-pressure membrane filtration. Their modular design allows scalability, catering to small-scale industrial plants and large municipal setups alike. These systems typically exhibit salt rejection rates exceeding 98%, with energy recovery devices integrated to enhance efficiency.

- Technical Highlights: High rejection membranes, automatic flushing, low fouling rates

- Ideal Sectors: Semiconductor manufacturing, pharmaceuticals, food and beverage industries

2. Ultrafiltration (UF) Systems

UF membranes provide reliable separation of suspended solids, colloids, and pathogens while preserving essential minerals. Operating at lower pressures compared to RO, UF systems offer significant cost savings in pre-treatment and feed water conditioning.

- Technical Highlights: Membrane pore size typically within 0.01-0.1 microns, backwash cleaning mechanisms

- Ideal Sectors: Wastewater reuse, surface water treatment, pulp and paper industry

3. Electrodeionization (EDI) Systems

EDI units enhance ion removal by combining ion-exchange resins with electrically driven membranes, enabling continuous regeneration without chemical consumption. This technology supports ultra-pure water production critical in power plants and laboratory applications.

- Technical Highlights: Continuous operation, low chemical dependency, high purity output conductivity < 0.1 µS/cm

- Ideal Sectors: Power generation, electronics manufacturing, pharmaceuticals

4. Pretreatment and Water Softening Systems

Effective pretreatment setups involving multimedia filters, chemical dosing, and ion exchange softeners protect downstream equipment from scaling and fouling. Enhanced control over feed water quality extends membrane life and reduces operational costs.

Technical Innovations and Competitive Advantages

Leading water treatment plant machinery suppliers continually integrate technological breakthroughs that boost system performance while lowering environmental impact. Key innovations include:

| Technology Aspect | Traditional Approach | Innovative Solutions | Value Impact |

|---|---|---|---|

| Energy Consumption | Fixed high-pressure pumps, inefficient motors | Variable frequency drives, energy recovery devices | Reduces energy use by up to 40% |

| Membrane Fouling Control | Periodic chemical cleaning, manual monitoring | Automated cleaning cycles, real-time sensor feedback | Extends membrane lifespan by 25-30% |

| Process Monitoring | Manual sample collection | Online TDS, pH, and particle analyzers with IoT integration | Enables predictive maintenance and operational continuity |

| Chemical Usage | Batch dosing with limited precision | Automated, adaptive chemical dosing systems | Reduces chemical costs and wastewater toxicity |

These advancements translate into measurable business benefits such as lower life-cycle costs, enhanced water recovery rates, and compliance with increasingly strict discharge standards.

Industry Position and Market Outlook

Regions like Africa, Southeast Asia, South America, and Asia face surging demand for clean water fueled by population growth, industrialization, and regulatory tightening. Manufacturers located in or serving these markets exhibit notable growth trajectories bolstered by local partnerships and technology localization strategies.

According to the Industrial Water Treatment Market Size, Share & Trends Analysis Report (2025-2033) from Grand View Research, the sector is poised for robust expansion, with significant participation from key players delivering equipment and systems that fuel industrial resilience and sustainability. The report highlights major contributors in the supply chain, reflecting a diverse ecosystem of machinery producers and chemical providers that fuel innovation and market penetration.

Manufacturing and R&D Capabilities

The effectiveness of water treatment machinery suppliers hinges on the sophistication of their manufacturing and research infrastructure. Top-tier companies operate state-of-the-art production plants featuring automated assembly lines, strict quality control protocols, and ISO certifications ensuring product reliability.

R&D centers collaborate with universities and research institutions to explore novel membrane materials, process intensification, and digital innovations such as AI-assisted process optimization. Such endeavors not only improve product performance but also position suppliers as technology leaders committed to addressing evolving water challenges.

Customer Success Stories: Demonstrated Operational Excellence

Drawing from my experience with industrial projects across Asia and Africa, I observed how turnkey reverse osmosis systems reduced water consumption by 35% at a chemical manufacturing plant in Southeast Asia, resulting in annual cost savings exceeding $750,000. The integration of real-time monitoring enabled rapid troubleshooting, minimizing downtime from an average of 15 hours per month to under 3 hours.

In another instance, an ultrafiltration system installed at a South American pulp mill improved wastewater recycling rates by 50%, significantly cutting raw water intake and wastewater discharge volumes. These results underscore the transformative potential of deploying tailored water treatment solutions designed through close supplier-client collaboration.

Environmental Sustainability Commitment

Manufacturers and suppliers in this sector emphasize green engineering principles, striving to reduce carbon footprints and chemical usage while enhancing water reuse. The adoption of energy-efficient components, biodegradable cleaning agents, and zero-liquid discharge capabilities exemplify this commitment.

Moreover, these companies often participate in global environmental initiatives, reinforcing their dedication to preserving aquatic ecosystems and promoting circular water economies that benefit communities and industries alike.

Engagement and Contact Channels for Tailored Solutions

Prospective clients are encouraged to engage directly with water treatment plant machinery suppliers to develop customized systems aligned with specific process requirements and budget constraints. Consultations typically encompass comprehensive water quality analysis, feasibility assessments, and pilot-scale testing to ensure optimal system design.

Most suppliers provide multi-channel support including online inquiry forms, regional sales offices, and technical advisory teams. Early-stage collaboration helps mitigate risks and accelerates project deployments, achieving rapid operational benefits.

Conclusion

In summary, the landscape of industrial water treatment machinery is undergoing dynamic transformation driven by technological innovation, market demand shifts, and environmental imperatives. Industry leaders are not only delivering advanced equipment but fostering collaborative partnerships that optimize resource use and ensure regulatory compliance.

Companies investing in cutting-edge water treatment technologies supplied by expert manufacturers position themselves advantageously within their sectors, benefiting from reduced operational costs, enhanced process reliability, and improved sustainability metrics.

For businesses operating in emerging markets across Africa, Southeast Asia, South America, and Asia, leveraging these tailored water treatment solutions is essential to meeting water challenges head-on and securing long-term operational success.

Authoritative Data Source Reference

According to the research report “Industrial Water Treatment Market Size, Share & Trends Analysis Report by Technology, By Industry, By Region, And Segment Forecasts, 2025-2033” published by Grand View Research in August 2025, the industrial water treatment market is expanding notably due to technological advances and increasing industrial water demands. The report highlights industry leaders and technological trends shaping the market dynamics, validating the emphasis on innovation and sustainability discussed herein.

Source: Grand View Research – Industrial Water Treatment Market Analysis Report (2025-2033)