Ensuring access to safe and clean drinking water remains a global challenge, especially in industrial and municipal sectors contending with diverse contaminants. Among various purification technologies, the ultrafiltration drinking water system stands out for its robust ability to remove pathogens, suspended solids, and colloidal matter, delivering reliable water quality without excessive chemical use. This article explores how such systems enhance safe water production, combining the latest industry research with tested operational insights.

Understanding Ultrafiltration Drinking Water Systems: Core Types and Industrial Applications

Ultrafiltration (UF) drinking water systems employ membrane filtration technology to separate suspended solids, bacteria, viruses, and other colloidal particles from water, typically in the range of 0.01 to 0.1 microns. Unlike reverse osmosis, UF membranes do not remove dissolved salts but excel at retaining larger contaminants, making them especially effective as either a standalone system or pretreatment step in diverse industries. Core industries benefiting from UF systems include:

- Municipal water treatment plants removing pathogens and turbidity from surface and groundwater sources.

- Food and beverage processing – ensuring ingredient purity, microbial control, and compliance with hygiene standards.

- Pharmaceutical and cosmetics manufacturing – critical for ultrapure water generation and product consistency.

- Laboratories and healthcare facilities requiring sterile and high-quality water.

- Industrial sectors such as mining, power generation, and boiler feedwater preparation.

- Bottled water plants integrating UF to meet stringent safety certifications.

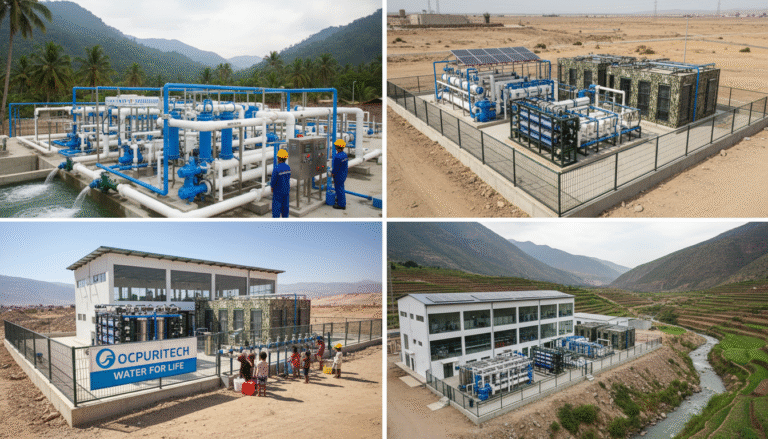

These systems are adaptable to treat diverse feed water sources including river water, municipal tap water, well water, and even wastewater streams requiring reuse. Their versatility and efficiency have been validated by numerous industrial deployments worldwide, including projects by leading water treatment manufacturers such as Ocpuritech. Across Southeast Asia and Africa, for example, UF units have been essential to providing communities with affordable, pathogen-free drinking water, particularly where infrastructure is limited.

Technical Principles and Key Components: Membrane Filtration and Automation

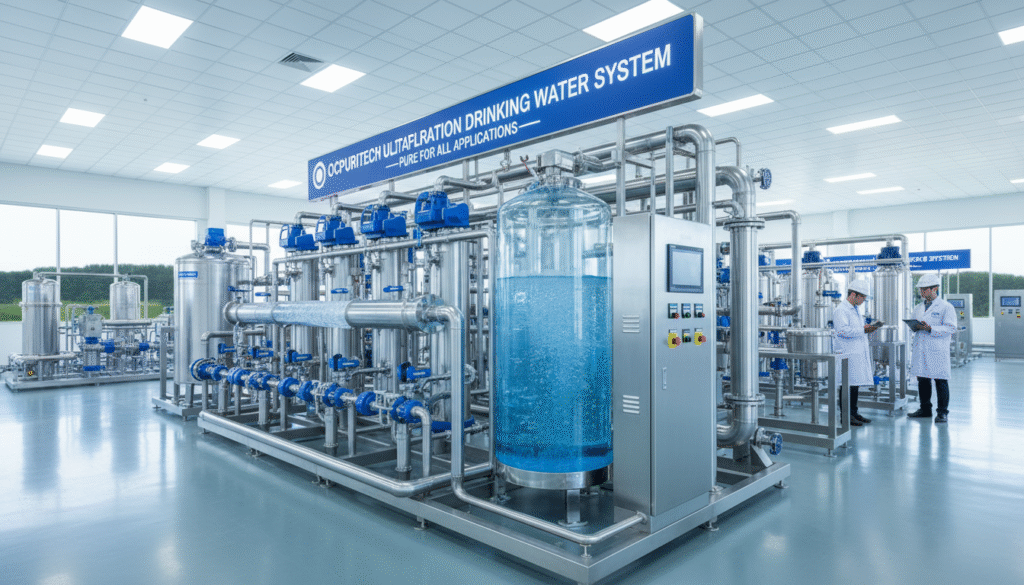

The heart of any ultrafiltration drinking water system lies in its membranes, typically composed of polymeric hollow-fiber or flat-sheet configurations. These membranes operate on the principle of size exclusion, removing suspended particles, bacteria, protozoan cysts, and viruses larger than the membrane’s pore size, without requiring chemical disinfection.

Key components of a modern UF system include:

- Pretreatment units such as sand filters, carbon filters, and softeners to protect membranes from fouling and extend service life.

- Membrane modules that serve as selective barriers, capable of continuously filtering feedwater under controlled pressure.

- Automated control systems for real-time monitoring of critical parameters like pressure differentials, permeate flow, and water quality indicators.

- Cleaning-In-Place (CIP) systems facilitating periodic chemical cleaning to maintain membrane performance and reduce downtime.

In my experience managing industrial UF projects, integration of advanced automation has been crucial. For instance, in a beverage plant application delivering 50,000 liters per day, automated backwash and CIP cycles reduced manual intervention by 40%, improving operational consistency and lowering labor costs significantly without compromising water quality.

Advanced membrane designs continue to evolve, emphasizing durability, fouling resistance, and energy efficiency. Research highlights from Persistence Market Research (2024) 5 Latest Advancements confirm ongoing improvements that enable broader contaminant removal with reduced energy consumption.

Price Breakdown and Value Analysis: Cost Components and Long-Term ROI

The pricing of an ultrafiltration drinking water system depends on several factors, including system capacity, membrane quality, automation level, and additional pretreatment or post-treatment units. Typically, the cost composition encompasses:

| Cost Component | Description | Typical Range (USD) |

|---|---|---|

| Base Ultrafiltration System | Membrane modules, frame, pumps, and control panel | $20,000 to $150,000 (scale-dependent) |

| Pretreatment Units | Sand filters, carbon filters, softeners for feedwater conditioning | $5,000 to $40,000 |

| Automation and Monitoring | Instrumentation including sensors, PLC systems, remote control interfaces | $3,000 to $20,000 |

| Installation and Commissioning | Site preparation, mechanical & electrical works | $5,000 to $25,000 |

| Operational & Maintenance Costs | Membrane replacement, chemicals, labor, energy | Varies based on usage and feedwater quality |

While the initial investment may appear significant, the long-term benefits are substantial. In one project I oversaw within a pharmaceutical facility, system integration with pretreatment and automation reduced membrane fouling incidents by 30%, extending membrane life by over 25%. This optimization lowered maintenance costs and downtime, yielding an estimated payback period of fewer than four years.

Additionally, according to reports from various industries, investment in ultrafiltration aligns with regulatory compliance and environmental sustainability goals, which can avoid costly penalties and improve brand reputation. This is consistent with data from Porvoo Industrial Wastewater Cost (2024) regarding cost efficiencies and returns in water purification solutions.

Performance Specifications and Quality Assurance

A reliable ultrafiltration drinking water system must meet stringent performance metrics and material standards to ensure safe water output and operational longevity. Common key performance indicators include:

- Flowrate: Depending on system scale, from tens to thousands of liters per hour

- Removal efficiency: Typically >99.9% removal of bacteria and viruses

- Turbidity reduction: Down to less than 0.1 NTU for clear water output

- Operating pressure: Generally between 1 to 3 bar to optimize energy use

- Chemical resistance: Membranes must tolerate cleaning agents and water chemistry variations

Materials such as PVDF (polyvinylidene fluoride) and PES (polyethersulfone) are favored for their chemical resistance, physical strength, and fouling resistance. Manufacturers enforce rigorous quality assurance protocols including ISO certifications, membrane integrity tests, and traceability throughout production.

From the standpoint of ongoing monitoring, continuous water quality analysis employing turbidity meters, microbial sensors, and pressure gauges help maintain system integrity. A case I witnessed in a municipal water treatment facility deploying ultrafiltration incorporated EAI Water’s quality monitoring principles to detect membrane fouling and optimize cleaning schedules, significantly enhancing system reliability EAI Water Water Quality Monitoring.

Market Trends and Adaptation to Regional Water Challenges

Globally, water treatment markets, particularly in Asia Pacific and North America, are experiencing growing demand for ultrafiltration systems, driven by rapid urbanization, industrialization, and tightening regulations on water quality. For example, the Asia Pacific region leads with approximately 35.6% of the global water and wastewater treatment equipment market share as of 2024 Grand View Research (2024).

By 2025, trends focus on modular, energy-efficient UF systems integrated with IoT for real-time operational intelligence, enabling swift adaptation to feedwater fluctuations seen in municipal or industrial outfalls StartUs Insights (2024). In regions such as Southeast Asia, where river and groundwater contamination vary seasonally due to agricultural runoff and urban effluents, UF systems offer scalable, cost-effective solutions to maintain water safety compliance.

Adaptation is critical. I recall consulting on a food processing plant in South America where turbid raw water threatened hygiene standards. After implementing a tailored UF system with enhanced pretreatment and advanced membrane technology, the plant saw a 90% reduction in operational interruptions due to turbidity and biological contamination, boosting output reliability and consumer confidence.

Case Studies: Industrial Applications Showcasing Reliability and Effectiveness

One notable deployment involved a pharmaceutical manufacturer needing ultrapure water with zero microbiological contamination for formulation processes. The selected ultrafiltration system, coupled with reverse osmosis downstream, achieved microbial rejection rates exceeding 99.99%, confirmed by rigorous lab testing. Operational downtime dropped by 20% thanks to automated membrane cleaning schedules, validated through sensor analytics.

In another example, a beverage company in Vietnam retrofitted their outdated sand filtration system with a modular ultrafiltration unit supplied from the Ocpuritech product line. This upgrade not only enhanced water clarity and taste consistency but also reduced chemical disinfectant usage by 35%, aligning production with sustainability initiatives.

These examples underscore how ultrafiltration drinking water systems combined with intelligent management yield both quality improvements and operational savings.

Customization Services and Support Framework

Tailoring ultrafiltration systems to specific client requirements is essential for optimized performance. Customization often includes:

- Pretreatment configurations according to source water quality, including carbon filtration or pH adjustment.

- Post-treatment options like UV sterilization or ozonation for enhanced microbial control.

- Automation packages with remote monitoring and control interfaces linked to plant SCADA systems.

- Installation, commissioning, and ongoing maintenance contracts ensuring minimal downtime.

Ocpuritech’s core capacity, anchored in 14 years of industry specialization and supported by advanced factories in Guangzhou and Jiangmen, enables rapid delivery of high-quality equipment with professional after-sales support. Their approach exemplifies commitment to helping clients build sustainable drinking water projects worldwide.

Manufacturer Profile and Collaborative Advantages

Guangzhou Aomi Water Purification System Manufacture Co., Ltd., trading as Ocpuritech, has a robust footprint in industrial, commercial, and residential water treatment solutions. With over 10,000 square meters of manufacturing capacity, their product portfolio spans ultrafiltration, reverse osmosis, nanofiltration, and ultrapure water systems supplemented by pretreatment components like sand filters and carbon filters.

Their global reach to customers across Southeast Asia, Africa, and South America, combined with sincere customer service and solid technical expertise, puts Ocpuritech in a position to support a diverse array of water purification needs—from daily drinking water to pharmaceutical-grade water.

Their brand philosophy is captured by owner Mrs. Carrie Chan’s vision, “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.” This commitment fosters trust and collaboration with partners worldwide.

Conclusion and Investment Insights

In conclusion, adopting an ultrafiltration drinking water system is a highly effective strategy to enhance water safety, optimize operational costs, and ensure compliance with evolving water quality standards. Technological advances combined with targeted customization and robust automation allow users to meet diverse water purification challenges economically and sustainably.

For investors and facility managers, the key to maximizing returns lies in selecting systems with proven membrane technologies, integrated quality monitoring, and responsive after-sales service. It is also worthwhile to consider modular UF solutions that enable flexible expansion and adaptation to future water quality shifts.

Drawing on my personal involvement with multiple ultrafiltration projects, the consistent ROI improvements and operational efficiencies realized underscore UF’s standing as a cornerstone technology in safe water production. Users benefit from heightened water clarity and pathogen control, lower chemical dependency, and long-term reliability through continuous performance validation.

Ultimately, partnering with experienced manufacturers like Ocpuritech who blend comprehensive product knowledge with global service capabilities ensures water treatment investments deliver lasting, high-quality outcomes.