Introduction

In today’s industrial landscape, ensuring the availability of clean and safe water has become a critical priority for maintaining public health and operational efficiency. An industrial RO water treatment plant serves as a pivotal solution for purifying large volumes of water by effectively removing contaminants, thus fostering healthier outcomes across various sectors.

With the global water treatment systems market valued at approximately $77.08 billion in 2023 and projected to grow at a compound annual growth rate (CAGR) of 6.3% through 2030, the industry is witnessing rapid technological advancements and increasing demand for efficient water purification technologies. This growth is driven largely by the escalating generation of industrial wastewater and an amplified focus on environmental sustainability.

My professional journey of over a decade in water treatment solutions has provided me with firsthand experience in deploying and optimizing industrial RO water treatment plants across different commercial and industrial applications. This article synthesizes authoritative market insights and practical case studies to provide a comprehensive understanding of innovative tactics in this technology.

Application Background and Market Demand Analysis

Water quality challenges vary globally but consistently revolve around the presence of suspended solids, dissolved salts, microbial contaminants, and industrial pollutants. Particularly in regions with dense industrial activity or limited natural freshwater sources, the demand for advanced purification solutions escalates significantly.

Stakeholders, from municipal utilities to manufacturing plants, are increasingly prioritizing access to safe drinking water not only for compliance but also to protect workforce health and support environmental stewardship initiatives. This shift aligns with consumer awareness of waterborne diseases and environmental degradation.

Enhanced regulatory frameworks and corporate social responsibility commitments are catalyzing investments toward high-efficiency water treatment systems capable of addressing these multifaceted demands.

Technical Principles of Industrial Reverse Osmosis Systems

Reverse osmosis (RO) technology operates on the principle of applying pressure to force water molecules through a semi-permeable membrane, effectively separating dissolved salts, organic compounds, bacteria, and viruses from water. The key components include:

- High-pressure pumps: Ensure adequate pressure for membrane filtration generally between 150 to 800 psi depending on feed water quality.

- Membrane modules: Thin-film composite membranes designed to reject particles as small as 0.0001 microns.

- Prefiltration units: Remove larger particulates and protect membranes from fouling.

- Post-treatment units: Adjust pH levels and add minerals to ensure water quality standards.

These systems can typically reduce total dissolved solids (TDS) by up to 99%, removing heavy metals, salts, and harmful microorganisms, ensuring highly purified water suitable for industrial processes or potable use.

Company and Product Overview

The growing emphasis on water conservation and quality has led to significant investments by water technology providers in research and development tailored to industrial needs. Companies specializing in industrial RO water treatment plants have expanded their footprint both globally and locally by innovating modular designs and adaptive technologies meeting regional water quality challenges.

One strategic focus has been the customization of membrane configurations and integration of smart control systems to optimize operational efficiency under varying feedwater conditions. These advancements ensure robust performance with reduced energy consumption and maintenance requirements.

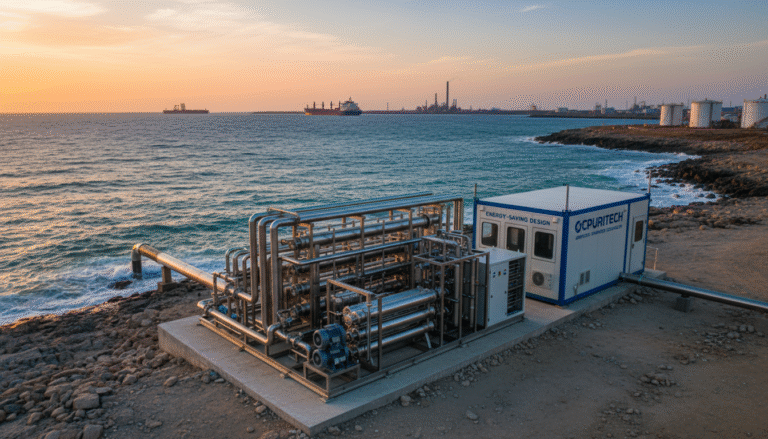

The versatility of these systems enables deployment in diverse environments, from arid zones requiring desalination to industrial zones grappling with heavy metal contamination.

Product Features and Advantages

Modern industrial RO plants share several hallmark features that contribute to sustainable and reliable operation:

- Energy-efficient design: Use of energy recovery devices and optimized pump motors to lower operational expenses.

- Intelligent control systems: Real-time monitoring with automated cleaning protocols to prevent membrane fouling and extend lifespan.

- Compact modular layouts: Facilitate easy installation and scalability according to production demands.

- Corrosion-resistant materials: Ensure durability in harsh chemical or saline environments.

The integration of these features yields numerous benefits:

- Improved water quality with consistent purity for critical industrial applications.

- Reduction of operational downtime and maintenance costs through system automation.

- Lower environmental footprint via minimized chemical usage and energy consumption.

- Enhanced health and safety standards by effectively removing hazardous contaminants.

Multi-Industry Application Cases

In my experience consulting for industrial water projects, I have witnessed the transformative impact of industrial RO water treatment plants across several sectors:

- Food and Beverage Industry: A bottling plant adopted a tailor-made RO system that reduced total dissolved solids from 750 ppm to less than 50 ppm, ensuring product taste consistency and meeting stringent FDA standards. This resulted in a 15% reduction in production interruptions linked to water quality issues.

- Pharmaceutical Manufacturing: Implementation of a high-precision RO plant enabled removal of trace heavy metals and microbial contaminants, essential for sensitive formulations. The system’s automated cleaning protocols cut maintenance time by 30%, significantly increasing uptime.

- Hospital Facilities: A healthcare provider integrated a commercial-scale RO system into its dialysis water preparation, achieving water quality surpassing international medical water standards, thereby improving patient safety and reducing infection risks.

These case studies highlight the adaptability and critical value of RO systems in meeting both regulatory compliance and operational excellence.

Installation and Maintenance Guidelines

Successful deployment of industrial RO water treatment plants relies on meticulous planning and ongoing maintenance:

- Installation: Should be conducted by certified technicians ensuring proper alignment of pumps, membranes, and electrical components. Site evaluation must account for feedwater quality variability and space constraints.

- Commissioning: Systems require initial flushing and testing to verify rejection rates and flow parameters meet design specifications.

- Maintenance: Routine membrane cleaning schedules recommended every 3 to 6 months based on fouling rates. Monitoring of pressure differentials and permeate quality guides timely interventions.

- Local Support: Establishing regional service centers ensures minimal downtime and boosts customer confidence.

Competitive Analysis and After-Sales Assurance

Compared to other filtration techniques such as ultrafiltration or ion exchange, RO offers superior removal rates for dissolved solids and a broader spectrum of contaminants. Although initial costs may be higher, the long-term savings in operational efficiency and water quality justify the investment.

Most industrial RO system suppliers provide comprehensive warranties covering membrane integrity and system components, backed by structured after-sales support including remote diagnostics and training programs. These assurances mitigate installation risks and enhance lifecycle value.

Customer Feedback and Success Narratives

Feedback from clients underscores the tangible benefits of adopting industrial RO water treatment solutions. One manufacturing plant reported a 20% reduction in water-related operational defects within six months of commissioning their RO system. Another user praised the reduction in chemical cleaning frequency, aligning with their environmental sustainability goals.

These testimonials reflect not only improved water quality but also broader organizational gains in efficiency, compliance, and environmental responsibility.

Conclusion and Call to Action

Industrial reverse osmosis water treatment plants stand as a cornerstone technology in achieving healthier water outcomes amidst mounting industrial and environmental challenges. Their technological sophistication, paired with proven operational benefits, make them indispensable for sectors demanding stringent water quality.

For enterprises and utilities aiming to safeguard public health, optimize production, and advance sustainability objectives, investing in tailored industrial RO water treatment plant solutions is a strategic move. I encourage stakeholders to explore these systems in depth and collaborate with experienced providers to harness their full potential.

References

According to Grand View Research’s January 2024 report titled “Water Treatment Systems Market Size, Share & Trends Analysis Report By Technology (Membrane Separation, Disinfection), By Application (Industrial, Municipal), By Region, And Segment Forecasts, 2024 – 2030,” the global water treatment market reflects robust growth influenced by technological progress in membrane separation, including industrial RO systems. This authoritative source confirms the critical role of RO technology in addressing rising industrial wastewater challenges and meeting expanding demand for commercial water purification plants.