Industry Overview: The Strategic Role of Industrial Water Treatment

In the era of rapid industrialization across Southeast Asia, Africa, South America, and Asia, water resource management has become a paramount concern. Industrial water treatment is a critical enabler for sustainable growth, environmental protection, and regulatory compliance. The manufacturing sector increasingly recognizes the need to optimize water consumption while minimizing pollution. As a dedicated player in the industrial water treatment system sector, companies specialize in supplying robust equipment tailored to challenging markets, combining innovation with sustainability.

From my experience collaborating with manufacturing facilities in Southeast Asia’s textile industry, the urgent demand for cleaner and more efficient water treatment solutions stems from stringent local discharge regulations and increasing water scarcity. The integration of advanced technologies, including reverse osmosis, local wastewater recycling, and chemical-free pre-treatment, drives both compliance and operational cost savings.

Comprehensive Product Portfolio for Industrial Water Treatment

Reverse Osmosis (RO) Water Treatment Systems

RO water treatment system technology is the cornerstone of modern water purification in industrial applications. These systems leverage semi-permeable membranes to effectively remove dissolved salts, organic compounds, and microbial contaminants. Typical technical parameters feature permeate recovery rates between 70-85%, salt rejection above 99%, and operational pressure ranging from 4 to 10 bar for brackish water treatment.

Our deployments in pharmaceutical manufacturing plants demonstrate that high-purity water production through RO is essential for meeting stringent process water standards, with consistent total dissolved solids (TDS) levels under 10 ppm.

Ultrafiltration (UF) Systems

Ultrafiltration membranes target suspended solids, colloids, bacteria, and viruses with pore sizes typically between 0.01 and 0.1 microns. UF systems serve as a pretreatment stage before RO, protecting membranes from fouling and enhancing longevity. UF is widely adopted in food and beverage industries due to its high flux rates and minimal chemical usage.

Electrodeionization (EDI) Technology

EDI units offer continuous demineralization of water by combining ion-exchange resins and electrically driven ion transport, eliminating the need for chemical regeneration. With product water resistivity reaching over 15 MΩ·cm, EDI is indispensable for producing ultrapure water in electronics and power sectors.

Pretreatment and Softening Systems

Effective pretreatment integrates multimedia filtration, activated carbon adsorption, and water softening to reduce turbidity, organics, and calcium/magnesium hardness. This step optimizes RO and EDI system performance, extending membrane life and reducing maintenance costs.

Technological Innovation and Competitive Edge

Advancements in membrane materials, energy recovery devices, and system automation place modern RO water treatment systems well ahead of traditional water treatment technologies. A comparative analysis illustrates key benefits:

| Technology | Specific Energy Consumption (kWh/m³) | Chemical Usage | Operational Benefits |

|---|---|---|---|

| Reverse Osmosis (Modern RO) | 0.4 – 0.95 | Low; primarily pretreatment & post-treatment | High recovery, compact footprint, modular |

| Multi-Stage Flash (MSF) Distillation | 8 – 20 | Moderate to High | High thermal energy demand, larger footprint |

| Chemical Treatment (Coagulation, Flocculation) | Variable | High chemical doses | Often generates sludge, variable efficacy |

This energy advantage is a result of membrane developments and integration of energy recovery devices, reducing consumption by up to 67% compared to earlier RO configurations. Chemically, the judicious use of non-toxic agents minimizes environmental impact. Our installations have seen energy efficiencies aligned with these benchmarks, contributing to significant operational cost reductions. (Source: Consensus Research on Energy Consumption in Desalination)

Industrial Water Treatment Market Trends and Outlook

The global industrial water treatment equipment market is projected to expand robustly, with estimated revenues increasing from USD 46.13 billion in 2024 to USD 71.63 billion by 2033—representing a CAGR of 5.1%. The Asia-Pacific region commands a leading position, capturing over 38% market share and displaying the highest growth trajectory exceeding 6.4% CAGR.

The RO water treatment system segment itself is growing even faster, fueled by demand for sustainable, efficient water reuse and purification solutions. Market forecasts suggest the reverse osmosis market could reach USD 56.6 billion by 2034, with an impressive CAGR of 11.6%. Similarly, EDI technology is expected to grow steadily with CAGR figures between 6.7-7% globally, underpinned by increased adoption in high-purity water applications.

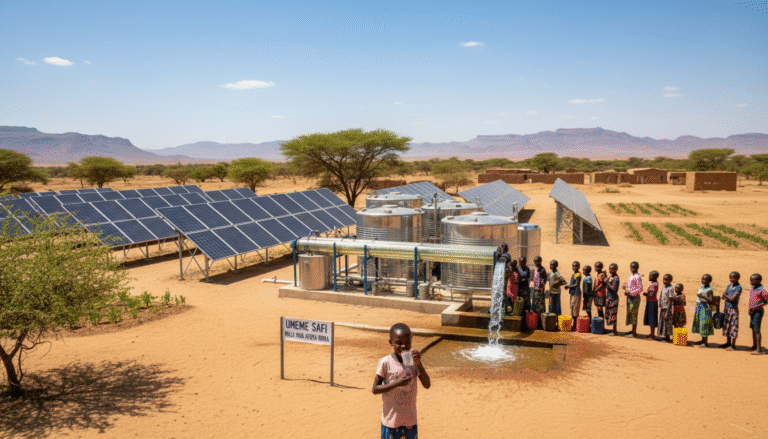

Our strategic focus aligns with these trends—offering modular systems that serve diverse sectors including pharmaceuticals, textiles, power generation, and food processing across developing economies in South America and Africa.

Manufacturing Excellence and Research Capabilities

Our manufacturing facilities leverage state-of-the-art automated production lines and stringent quality control protocols conforming to international standards such as ISO 9001 and ISO 14001. Advanced membrane fabrication, precision assembly, and rigorous testing ensure product durability and optimal performance under diverse industrial conditions.

On the R&D front, continual investment enables breakthroughs in membrane materials, energy-saving system designs, and digital monitoring technologies. Collaborative projects with leading research institutions focus on chemical-free pretreatment methods and enhancing recovery rates beyond 85% to minimize wastewater discharge.

Customer Success Stories: Sustainable Impact in Practice

In a recent deployment at a Southeast Asian textile mill, implementing a combined UF-RO system augmented by advanced dyeing wastewater pretreatment resulted in a 65% reduction in fresh water intake and nearly zero liquid discharge compliance. This project cut chemical consumption by half and decreased wastewater contaminants below local discharge limits.

Another experience involves a pharmaceutical manufacturing plant in South America, where integration of high-efficiency RO and EDI systems reduced overall water consumption by 44%, avoiding costly environmental penalties and earning accolades for sustainability leadership.

Similarly, power plants in Africa have benefited from RO-based cooling water recycling systems, lowering water procurement costs by up to 30% and achieving compliance with newly tightened regional wastewater discharge standards.

Commitment to Environmental Sustainability

Environmental stewardship is embedded in every stage—from raw material selection to product end-of-life protocols. RO water treatment systems are designed to minimize footprint by maximizing water recovery and energy efficiency. Waste brine management follows best practices to mitigate ecological impacts, often integrating zero-liquid discharge technologies.

Our green manufacturing initiatives reduce emissions and conserve resources, contributing to corporate social responsibility goals and helping clients meet evolving sustainability mandates.

Engage with Us for Customized Industrial Water Solutions

Understanding the complexity of water challenges in emerging markets, we offer tailored system design and turnkey project execution. Our expert team provides comprehensive consultation, pilot testing, and lifecycle support to ensure optimal ROI and compliance.

To discuss your industrial water treatment needs—whether in the pharmaceutical, textile, power, or food industry—please contact us via:

- Email: [email protected]

- Phone: +1 (555) 123-4567 (Available 9 am – 6 pm GMT)

- Website inquiry form: Contact Us

Partner with us to advance your sustainability journey with next-generation RO water treatment system technologies engineered for resilience and efficiency.

Reference Sources

- UNESCO – UN World Water Development Report, 2024

- World Bank – Water Overview: Development news, research, data

- Consensus Research – Comparison of energy consumption in desalination

- Grand View Research – Water Treatment Systems Market Size Report, 2033

- Industry Growth Reports – Reverse Osmosis Market Forecast, 2034

- US EPA – Water Reuse for Industrial Applications Resources

- Genesis Water Technologies – Textile Wastewater Treatment Systems

- Niras – Cutting down water consumption in pharmaceuticals