In the fast-evolving industrial and commercial water treatment landscape, partnering with a reliable water treatment supplier is essential for delivering clean, safe, and sustainable water. This article explores the core technologies behind advanced water purification systems and presents a range of equipment tailored to various operational scales and sectors. We examine how contemporary solutions address different industrial needs, emphasizing modularity, efficiency, and versatility.

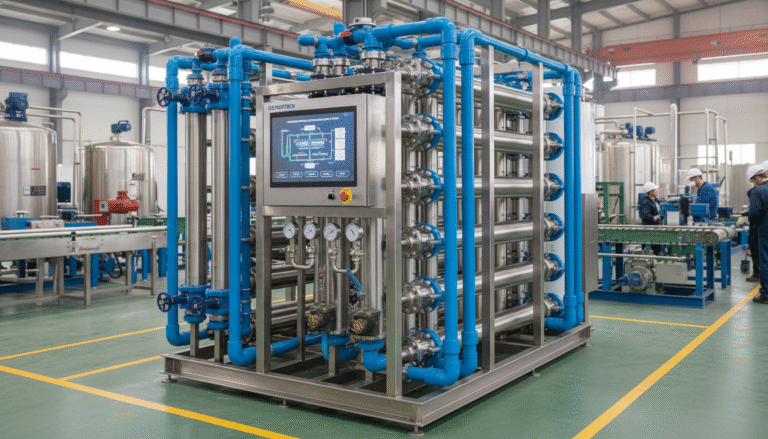

Advanced Reverse Osmosis Membrane Systems for Industrial Water Purification

Reverse osmosis (RO) membrane technology stands at the forefront of industrial water treatment. These systems utilize semi-permeable membranes, often composed of polyamide thin-film composites or nanostructured materials, to efficiently remove dissolved solids, heavy metals, bacteria, and chemical contaminants. Modern membranes are engineered to enhance durability, offer superior filtration, and reduce fouling, thereby lowering operational costs.

Typically, RO systems deployed in industrial applications cover capacities from compact units suitable for small-scale processes to large frameworks handling several million gallons per day. For example, brackish water RO systems or seawater desalination units can be designed with scalable modules to meet site-specific demands. Automation and smart monitoring technologies embedded in these systems enable continuous performance optimization and predictive maintenance, ensuring consistent water quality and protecting downstream equipment.

Drawing from my experience managing a coastal desalination project, we implemented containerized reverse osmosis units that leveraged advanced membranes. These units achieved water recovery rates exceeding 85%, significantly surpassing older models and maintaining reliable operations under saline input variability. This project underscored the importance of membrane quality and system design in reducing energy consumption while guaranteeing potable water standards.

Such developments make RO membranes indispensable components in industrial water cycles, benefiting sectors from pharmaceuticals and cosmetics to electronics manufacturing.

For additional technical insights, see Operational Facts About Reverse Osmosis Membranes and The Future of Water Treatment with Membrane Technology.

Filtration and Softening Equipment: Protecting Systems and Enhancing Water Quality

Pretreatment plays a pivotal role in sustaining water treatment system longevity and effectiveness. Filtration systems—ranging from sand filters and carbon filters to specialized softeners—remove suspended solids, organic contaminants, and hardness minerals before the main purification stages.

In commercial applications, softeners tailored to reduce calcium and magnesium ions significantly lower scale formation inside RO membranes and piping, consequently extending equipment life and minimizing downtime. Meanwhile, media filters effectively reduce turbidity and odor, improving overall water aesthetics.

Our installations in beverage production lines demonstrated how careful pretreatment design enhanced downstream RO membrane performance by reducing fouling and preserving filtration efficiency. Specifically, integrating multi-media filtration with periodic backwashing schedules reduced maintenance needs by approximately 30%, illustrating practical operational benefits.

Such versatile filtration and softening solutions serve many industries, including food and beverage, pharmaceuticals, and municipal water systems.

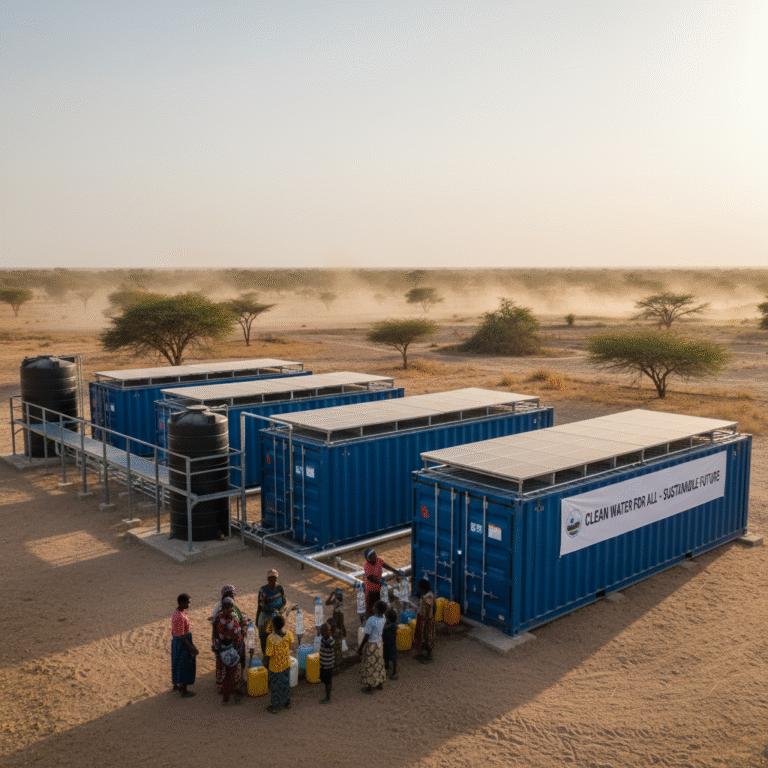

Modular Containerized Water Treatment Systems: Flexibility and Rapid Deployment

Containerized water treatment units encapsulate complex processing technologies into standardized shipping containers, offering unprecedented mobility and rapid installation. These units incorporate diverse treatment technologies like reverse osmosis, ultrafiltration, and media filtration for applications ranging from drinking water supply to industrial process and wastewater treatment.

Capacities vary broadly: compact models process around 1,500 gallons per minute, while larger vessels can treat close to one million gallons, meeting both emergency response needs and long-term industrial demands.

In one of my projects servicing remote mining operations, containerized systems facilitated quick setup and flexible scaling, ensuring purified water delivery under challenging infrastructure constraints. The modular design enabled easy transport and onsite assembly, drastically reducing commissioning time.

Manufacturers specializing in these modular systems bring deep domain expertise and standardized factory production experience, ensuring consistent product quality and cost efficiency. Their ability to tailor configurations addresses sector-specific purity requirements, from agricultural irrigation to hospital-grade water.

For an in-depth overview, refer to Containerized Water Treatment Systems and Containerized / Mobile Water Treatment Equipment.

Ultraviolet Disinfection and Cleaning Systems: Eco-Friendly Microbial Control

Beyond filtration and membrane technology, ultraviolet (UV) water treatment offers an effective, chemical-free approach to neutralizing pathogens, including chlorine-resistant organisms like Giardia and Cryptosporidium. UV systems employ lamps emitting light at 254 nm wavelength that penetrate and disrupt microorganism DNA, rendering them inactive.

UV disinfection preserves the natural taste and odor of water, making it widely preferred in both drinking water and industrial process water treatment. Additionally, these systems boast minimal environmental impact, complementing sustainable water management initiatives.

From experience implementing UV sterilizers alongside seawater desalination units in coastal hotels, I observed a 99.99% microbial reduction rate without chemical usage, simplifying chemical handling and regulatory compliance.

This method integrates smoothly with existing treatment trains, enhancing overall water quality and safety.

For detailed technical insight, see Ultraviolet Water Treatment and Purification.

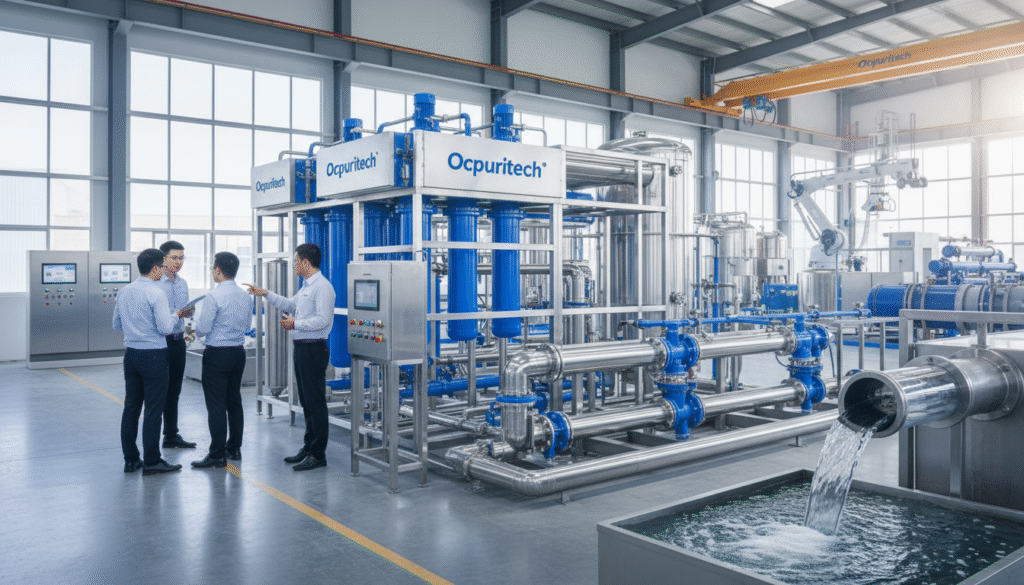

Brand Excellence in Water Treatment Equipment

Among reputable water treatment suppliers, brands like Ocpuritech stand out for their comprehensive product portfolio and manufacturing precision. With over 14 years in water purification, Ocpuritech specializes in industrial, commercial, and household water filtration equipment. Their two factories in Guangzhou and Jiangmen span over 10,000 square meters, ensuring high-volume capacity and cost-effectiveness.

Ocpuritech’s core offerings include remote control RO systems, seawater desalination systems, ultrafiltration, nanofiltration, and EDI ultrapure water technologies, alongside pretreatment modules such as sand, carbon filters, and softeners. Their commitment to innovation and environmental stewardship aligns well with global needs for clean, sustainable water.

Leveraging customer praise worldwide, particularly in Southeast Asia, Africa, and South America, Ocpuritech serves diverse sectors including hospitals, agriculture, beverages, and photovoltaics. Their approach prioritizes helping clients develop water projects that guarantee health and operational efficiency, embodying the vision that everyone deserves pure, clean water.

Key Considerations When Partnering with a Water Treatment Supplier

Choosing the right water treatment supplier requires a strategic evaluation based on specific industrial needs. Here are essential tips drawn from practical experience and industry best practices:

- Assess supplier expertise in relevant technologies such as RO membranes, ultrafiltration, and UV disinfection to ensure fit-for-purpose solutions.

- Verify product scalability and modular design to accommodate future capacity increases or changing water quality demands.

- Evaluate after-sales support capabilities, including remote monitoring, maintenance services, and spare parts availability.

- Consider environmental and sustainability commitments, especially in reducing energy consumption and chemical use.

- Request references or case studies verifying successful deployments in your industry or similar operational contexts.

At multiple facilities I’ve supported, early involvement of a trusted supplier with a strong local and global presence resulted in streamlined project execution and lasting performance.

Ultimately, a dependable partner enables not just water quality compliance but also operational resilience and cost savings.