Fully Automatic 150BPH Bottled Water Production Line

The 150BPH automatic bottled water production system is a fully automatic mineral water bottling solution designed for the home and office delivery (HOD) industry.

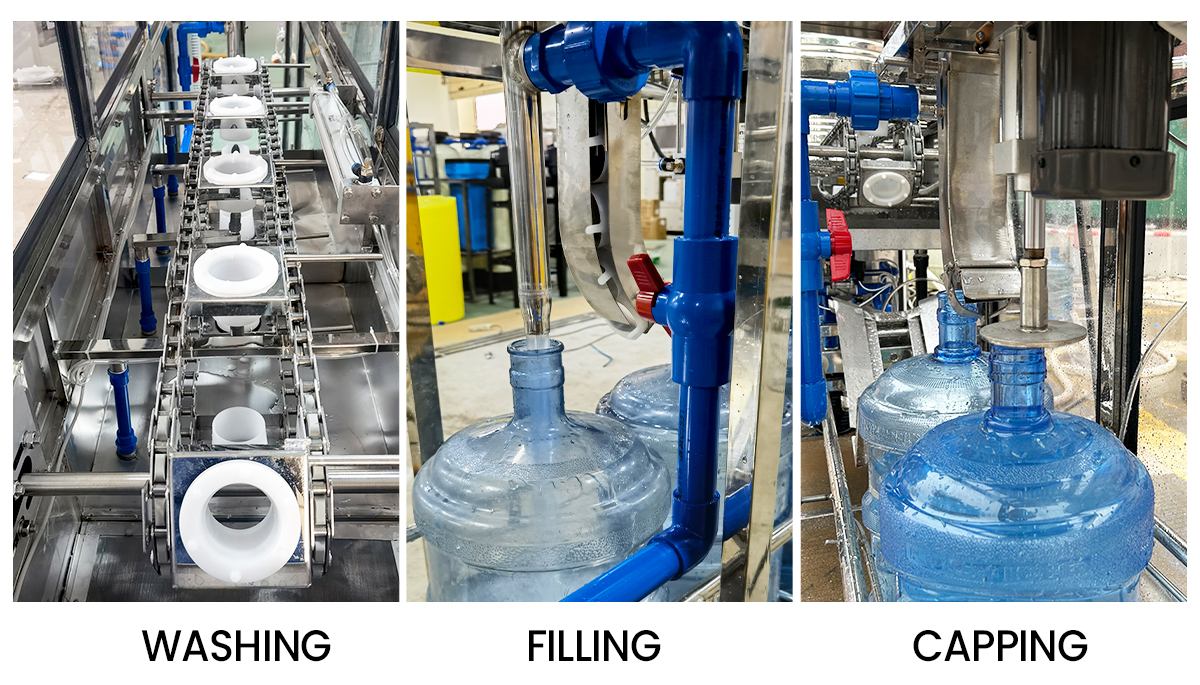

AOMI specializes in manufacturing 5 Gallon Water filling Machine, providing turnkey solutions that integrate bottle washing, sanitizing, filling, and capping into one efficient system with minimal labor requirements. This mineral water bottling solution is ideal for bottled drinking water factories seeking stable performance, hygienic operation, and long service life.

AOMI 5 Gallon Water Washing Filling Capping Monoblock Machine – Watch the Video

150BPH Automatic Washing, Filling and Capping Line for Large Bottles

The complete bottled water filling plant operates fully automatically. With minimal manual intervention, workers only need to place returned empty bottles onto the conveyor system. Designed as an integrated unit, the washing, filling, and capping system combines all key processes into one compact solution. It is suitable for filling and bottling 3 gallon, 5 gallon, and up to 6 gallon water bottles, making it a flexible solution for bottled water plants. The production line will automatically:

① Washing and sanitize bottles: The 5 gallon water filling machine features a fully automated bottle rinsing process to ensure reusable bottles are thoroughly cleaned and meet stringent hygiene standards. The system uses a multi-stage 5 gallon bottled water washing process, typically combining disinfectant solutions and purified water to remove dust, residues, and other contaminants from the bottles. Equipped with high-pressure jets and automated nozzles, the rinsing system targets both the interior and exterior surfaces of each bottle, ensuring that no impurities remain. Designed for efficiency, this automatic 5 gallon water bottle cleaning line minimizes water waste while complying with strict food-grade safety standards.

② Filling purified or mineral water: The 5 gallon water filling machine is designed for high-precision and high-speed water filling, delivering purified or mineral water into 5-gallon bottles with minimal spillage. The automatic 5 gallon bottled water filling line features specially engineered nozzles that minimize foaming and ensure water quality by reducing exposure to contaminants. This 5 gallon bottle filling system is ideal for factories requiring consistent, hygienic, and efficient water bottling operations, maintaining product safety while increasing production throughput. With this precision 5 gallon water bottling equipment, bottling plants can achieve reliable performance, improved efficiency, and compliance with strict food-grade safety standards.

③ Automatically capping and discharge finished bottles: The 5 gallon water filling machine includes a high-speed automatic capping system that secures bottles with airtight, tamper-evident caps, ensuring product safety and integrity. Using automated cap placement and pressing mechanisms, the system applies caps with consistent pressure, preventing leaks and contamination. Compatible with various 5 gallon bottle cap types, this 5 gallon bottled water capping line offers flexibility for different markets while maintaining efficient, reliable, and hygienic operation.

As a result, the automatic bottling line significantly reduces labor costs while improving production efficiency and hygiene standards.

Fully Automatic 5 Gallon Water Bottling Production Plant

- ✅ Food-grade SUS304 stainless steel for machine body and all water-contact pipes.

- ✅ Famous brand motor for cap unscrambling, ensuring stable and reliable operation.

- ✅ Strong stainless steel door stoppers instead of common magnets for enhanced safety.

- ✅ High-stability handles with exclusive reinforced structure.

- ✅ Advanced electrical components meeting international standards.

Operating at high speed with precise control, the drinking water filling system ensures stable and reliable output.The machine works reliably and efficiently based on compact structure and high automation technology. The machine is made of excellent stainless steel, which has the advantages of easy flushing and corrosion resistance.

Multiple built-in safety features further protect both the equipment and operators during operation. The automatic sealer guarantees tight and hygienic cap sealing, while the cap water-spraying sterilization system ensures aseptic conditions for bottled water. This 5 gallon water bottling production line can automatically complete bottle feeding, washing, sterilizing, filling, capping, counting, and finished product discharging.

Can the 5 Gallon Water Bottling Line Change Bottle Size?

The 5 Gallon Water Filling Machine is designed to operate with one fixed bottle size. You can set the machine for a bottle volume ranging from 3 gallons to 6 gallons during initial configuration. Once set, the bottle type cannot be changed frequently. This design aligns with global market standards, as most 5 gallon water bottles share similar dimensions, and frequent bottle changes are rarely required in actual production.

Reliable Support for Your 5 Gallon Water Bottling Plant

Customer satisfaction is our top priority. When you choose AOMI’s 5 gallon water bottling machine, you receive reliable technical support throughout the entire lifecycle of your production line. We are committed to helping you build, maintain, and optimize your 5 gallon mineral water bottling production plant for long-term success. Welcome to contact if you have any inquiry regarding the water problem.