Why Choose a Reverse Osmosis RO System? Advanced RO technology removes over 1,000 harmful contaminants—including bacteria, viruses, chromium, mercury, fluoride, lead, chlorine, iron, dissolved chemicals, and sediments—effectively purifying your tap or well water. It delivers water that is not only purer and safer, but also better-tasting than bottled water. If you are considering an Reverse Osmosis Water Filter Systems, contact us today for an affordable and effective water treatment solution.

Reverse Osmosis (RO) is a process that uses semi-permeable spiral wound membranes to separate and remove dissolved solids, organic, pyrogens, submicron colloidal matter, color, nitrate and bacteria from water. Feed water is delivered under pressure through the semi permeable membrane, where water permeates the minute pores of the membrane and is delivered as purified water called permeate water. Impurities in the water are concentrated in the reject stream and flushed to the drain is called concentrate water.

2000LPH Full Stainless Steel Compact Industrial Reverse Osmosis Plant

Feed water pump → quartz sand filter → activated carbon filter → water softener (optional) → security filter → high-pressure pump → RO membrane → ultraviolet sterilizer → pure water tank (or bottled water filling production line)

- Feed Water Pump: High quality stainless steel 304/316 pump for long-life usage. Choosing a high-quality raw water pump helps ensure the normal operation.

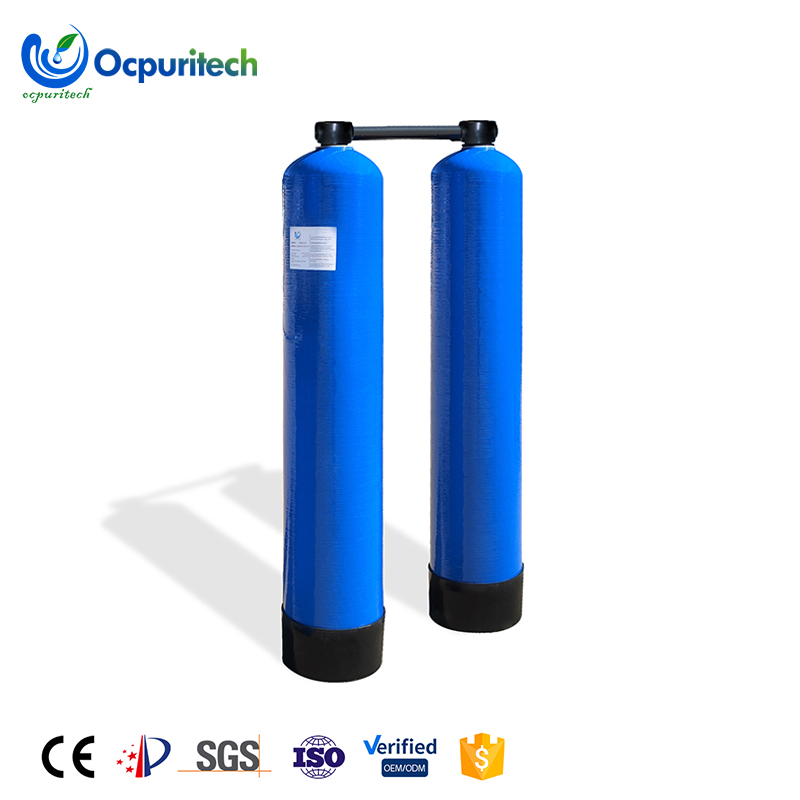

- Sand Filter: Using quartz sand and gravel to removingall physical impurities larger than 10 micron by FRP or SUS tank with multi-port valve.

- Carbon Filter: Using coconut-shell activated carbon to remove chlorine, odor & taste by a FRP or SUS tank with multi-port valve.

- Security Filter: 1 or 5 Micron PP filter cartridge to remove sediments and protect the reverse osmosis membranes.

- High Pressure Pump: High quality stainless steel 304/316 pump pressurizes reverse osmosis system.

- RO Membrane: Separating and removing dissolved solids, organic, pyrogens, submicron colloidal matter, color, nitrate and bacteria from water.

- UV Ultraviolet Sterilizer: Ultraviolet sterilizers in water treatment systems provide instant, chemical-free disinfection, effectively neutralizing bacteria and viruses without altering water taste or quality.

Also you can choose your ro system as containerized reverse osmosis water treatment plant.

What is the Electrical Power Consumption of Reverse Osmosis Water Filter Systems ?

It depends on capacity of ro water purifier plant as liter per hour or liter per day. So, our ro water treatment system power supply range is 220V to 480V with 50Hz or 60Hz.

In industrial water treatment, Reverse Osmosis (RO) systems stand out as a top-tier solution, delivering high-purity water efficiently and reliably. Essential for sectors like manufacturing, power generation, pharmaceuticals, and food & beverage, RO ensures consistent water quality for critical processes.

Industrial Reverse Osmosis Water Treatment – Application Scenarios

| Industry | Application Scenario | Water Source | Treated Water Use | Key Requirements |

|---|---|---|---|---|

| Food & Beverage | Ingredient water purification | Municipal water | Beverage production, food processing | Low TDS, stable water quality, hygienic design |

| Pharmaceutical | Process & purified water preparation | Municipal water | Drug manufacturing, formulation | High purity, compliance with GMP standards |

| Electronics & Semiconductor | Ultra-pure water pre-treatment | Municipal / Groundwater | Chip manufacturing, PCB cleaning | Extremely low conductivity, silica removal |

| Power Generation | Boiler feed water treatment | Municipal / Surface water | Steam generation systems | Low hardness, low conductivity, scale prevention |

| Chemical Industry | Process water desalination | Municipal / Brackish water | Chemical reactions, dilution | Corrosion resistance, stable output |

| Metallurgy | Cooling & process water | Surface / Industrial water | Cooling systems, metal processing | High recovery rate, reduced scaling |

| Textile & Dyeing | Process water purification | Groundwater / River water | Dyeing, washing processes | Color removal, consistent water quality |

| Desalination (Brackish) | Brackish water desalination | Brackish water | Industrial & domestic use | High salt rejection, energy efficiency |

| Bottled Water Plants | Drinking water production | Municipal / Groundwater | Bottled drinking water | Food-grade materials, taste optimization |

| Industrial Parks | Centralized water treatment | Mixed water sources | Multiple industrial users | Modular design, large capacity |

AOMI RO systems integrate cutting-edge technology with deep industry expertise, making them a trusted global leader in water treatment solutions for industrial, commercial, and residential use.