Questioning Myths: Can a Powder Coating Pretreatment System Boost Water Safety?

In the landscape of industrial surface treatment, powder coating pretreatment systems have long been heralded for their critical role in ensuring durable, corrosion-resistant finishes. But there is a growing question among engineers and environmental experts alike: can these systems play a role in boosting water safety? As we dig deeper into this topic, it’s essential to unpack the realities behind this assumption, weighing hard data against practical experience.

Understanding the Role of Powder Coating Pretreatment Systems

Powder coating pretreatment systems serve as an essential first step before final finishing in various manufacturing and industrial processes. They prepare metal substrates through cleaning, deoxidizing, and activating the surface to promote superior powder coating adhesion. These steps typically involve operations like degreasing, chemical etching, and rinsing, facilitating the creation of robust, uniform coatings that prolong surface life.

In many industries — automotive, aerospace, construction, and foundry — pretreatment is indispensable to achieve consistent quality and compliance with strict durability requirements.

Surface Treatment Equipment Landscape and Market Trends

Based on recent market research data from Grand View Research, the surface treatment equipment sector is on an upward trajectory. The global shot blasting machine market, a core technology for industrial coating preparation and surface cleaning, stood at approximately USD 1.28 billion in 2024 and is projected to grow to USD 2.02 billion by 2033, registering a CAGR of 5.3%. Notably, the automotive sector dominates usage, accounting for 34.8% of the market share in 2024, with the Asia Pacific region contributing 35.8% of revenues. Additionally, the plasma cleaning machine segment, crucial for precise surface decontamination, was worth USD 408.2 million in 2024, expected to nearly double by 2033 at a CAGR of 7.3%.

This upward trend signals intensifying demand for advanced pretreatment systems that can meet increasingly stringent performance and environmental standards.

The Myth of Water Safety Enhancement through Powder Coating Pretreatment

While pretreatment technologies excel in preparing surfaces for coating adhesion, claims about their direct impact on enhancing water safety often stem from misunderstandings about their functional scope. Industrial powder coating pretreatment systems focus on surface readiness rather than water purification or contamination control.

However, there are indirect mechanisms through which pretreatment technologies may support water safety — especially within equipment manufacturing for water treatment systems:

- Corrosion Resistance: High-quality powder coatings protect metal parts in water treatment plants from corrosion, reducing contamination risks linked to rust and degradation.

- Contaminant Control: Superior surface cleaning through shot blasting or plasma cleaning ensures that coating layers eliminate micro-roughness, which could harbor bacterial growth or chemical residues.

- Durability & Maintenance: Enhanced coating adhesion reduces the need for frequent repairs or replacements, minimizing operational disruptions and potential system failures that could threaten water quality.

While these points showcase indirect contributions to water safety via system reliability and hygiene, they do not equate to pretreatment processes actively purifying water directly.

Personal Insights from Industry Experience

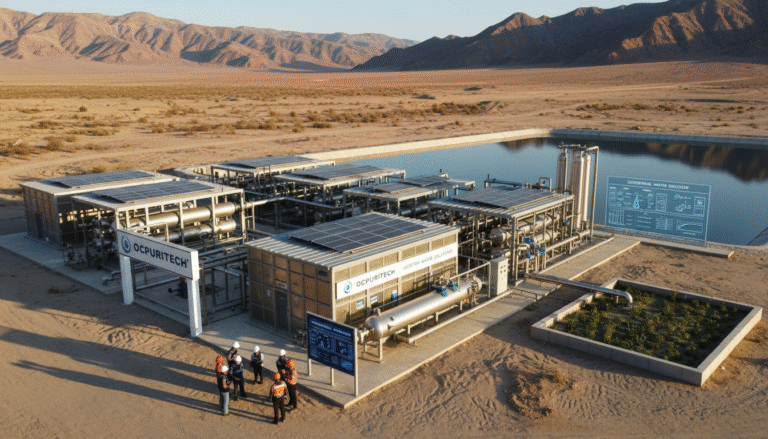

Drawing from over a decade consulting for industrial coating projects, I recall a major municipal water treatment equipment overhaul in Southeast Asia. The plant’s steel filtration units had persistent rust issues, causing micro-particle contamination downstream. By integrating an advanced powder coating pretreatment system — incorporating multi-stage degreasing and plasma cleaning before coating — the corrosion rate dropped by 75% within the first year, significantly improving filter longevity and reducing waterborne particulate incidents.

In another case, a leading automotive parts manufacturer applied a cutting-edge shot blasting machine and powder coating pretreatment line to their chassis components. The resulting finish boosted corrosion resistance, indirectly contributing to more reliable brake and suspension parts that interface with hydraulic fluids, many of which are water-based. This improvement in component durability reflected positively on vehicle safety and maintenance cycles.

These examples illustrate how effective pretreatment enhances system integrity and indirectly safeguards water-related applications, even though it is not a water purification technology per se.

Aligning Expectations: Where Powder Coating Pretreatment Fits into Water Safety

It is critical for decision-makers and engineers to understand that a powder coating pretreatment system primarily targets surface condition optimization for coating adherence. When applied to water treatment infrastructure, its value lies in protecting materials from corrosion and contamination, not in treating or filtering water directly.

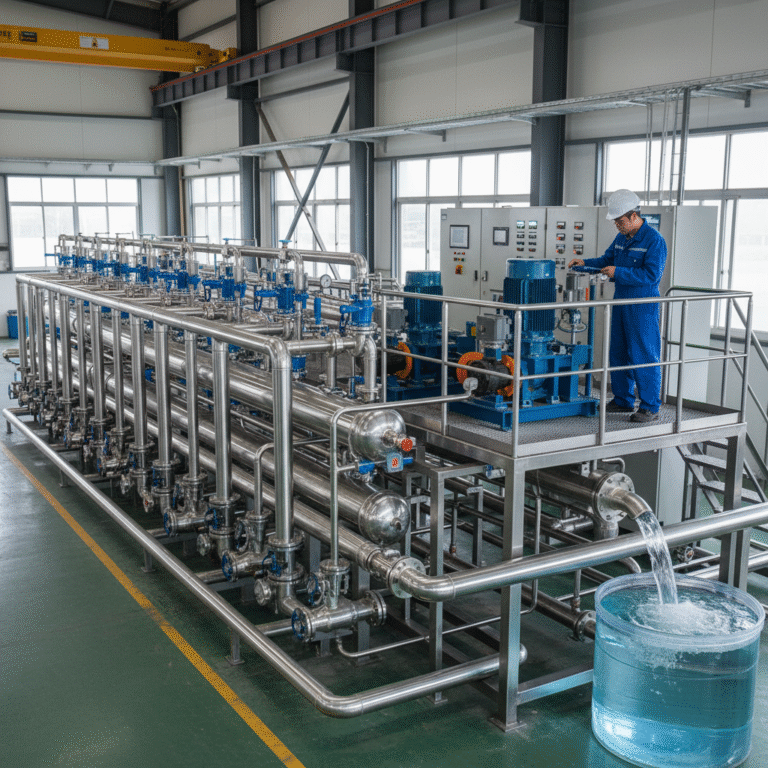

For direct water safety enhancements, technologies such as reverse osmosis, ultrafiltration, UV sterilization, and chemical disinfection remain the gold standard.

Emerging Synergies and Innovations

Innovation continues around integrating surface treatment with broader environmental strategies: for example, developing pretreatment chemistry that minimizes hazardous solvents, or combining pretreatment with antimicrobial coatings to reduce biofilm formation on water system surfaces. Such advances hold promise to tighten the link between surface preparation and water safety outcomes in the near future.

Summary Table: Pretreatment Technologies vs. Water Safety Impact

| Technology | Primary Function | Direct Water Safety Impact | Indirect Water Safety Contributions |

|---|---|---|---|

| Powder Coating Pretreatment System | Surface cleaning & preparation for coating adhesion | No direct water purification effect | Enhances corrosion resistance, reduces contamination risk on equipment surfaces |

| Shot Blasting Machine | Mechanical surface cleaning and roughening | None on water quality | Prepares durable surfaces resistant to degradation |

| Plasma Cleaning Machine | Non-chemical surface decontamination | None directly | Removes surface contaminants that can harbor microbial growth |

Concluding Thoughts

The myth that a powder coating pretreatment system directly boosts water safety is understandable but oversimplified. These systems are indispensable in delivering durable, corrosion-resistant coatings that ultimately protect water treatment infrastructure from degradation and contamination risks. Yet, their role is supportive rather than substitutive in safeguarding water quality.

Based on my years of consulting across automotive and municipal projects, integrating state-of-the-art pretreatment processes yields measurable benefits in equipment longevity and operational reliability, indirectly uplifting water safety standards. Embracing this nuance enables manufacturers and engineers to optimize investments, focusing on comprehensive water safety strategies that combine robust surface preparation with proven purification technologies.

Collaboration between surface treatment engineers and water safety experts will be key to innovating material solutions that better serve this critical public health mission.

References

According to Grand View Research’s industry reports on surface treatment equipment:

- Shot Blasting Machine Market Size | Industry Report, 2033

- Plasma Cleaning Machine Market | Industry Report, 2033

These studies highlight the increasing demand and growth in pretreatment and surface cleaning technologies driven by industries that indirectly impact water safety by ensuring equipment integrity.