Stunning Outcome: Industrial Ultrafiltration System Boosts Plant Performance

In regions struggling with limited water resources, reliable and efficient water treatment solutions are indispensable. Industrial ultrafiltration systems have emerged as a game-changer in enhancing water treatment performance, particularly within drinking water plants operating under challenging environmental conditions. This article delves into the critical role of industrial ultrafiltration systems in optimizing plant operations and ensuring sustainable access to safe drinking water.

Introduction: Water Scarcity and Public Health Imperatives

Water scarcity poses a dire threat to public health and economic development across many parts of the world. In particular, semi-arid regions face seasonal droughts, declining groundwater levels, and contamination risks, placing immense pressure on drinking water infrastructure. The necessity to provide clean, reliable drinking water is not merely a question of convenience—it is vital for preventing waterborne diseases, supporting agriculture, and enabling industrial activities that drive regional growth.

Traditional water treatment technologies often face limitations such as insufficient virus removal, high operational costs, or complex maintenance requirements. Here, industrial ultrafiltration systems present an effective, economically feasible alternative. They leverage membrane technologies to provide robust filtration that improves water quality, boosts plant throughput, and reduces downstream treatment strain. These benefits have been increasingly validated by global markets and research institutions.

Product and Technology Overview: Industrial Ultrafiltration Systems

At its core, an industrial ultrafiltration system comprises semi-permeable membranes designed to remove suspended solids, bacteria, viruses, and macro-molecules from raw water. Operating typically under low pressure (0.5 to 5 bar), ultrafiltration membranes come in configurations such as tubular, hollow fiber, and flat sheet, each optimized for different feed water characteristics and plant layouts.

Compared to conventional filtration, ultrafiltration achieves superior turbidity reduction and effectively removes organic pollutants measured by chemical oxygen demand (COD) reductions averaging 86%, along with virus removal rates exceeding traditional methods—an essential factor for potable water safety.

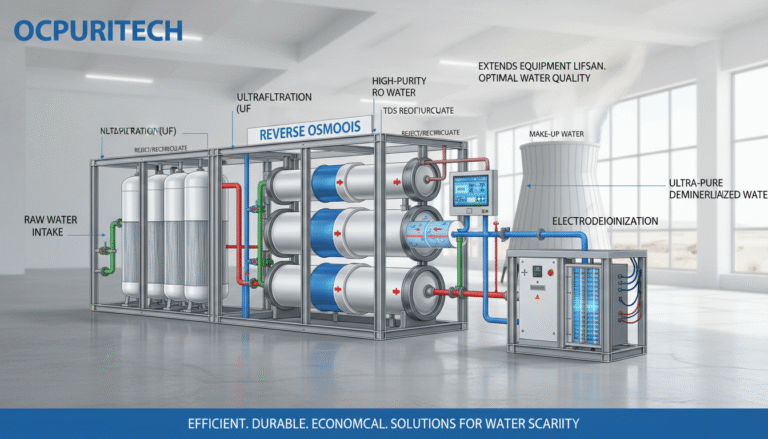

A common industrial application incorporates ultrafiltration as a pretreatment stage ahead of reverse osmosis (RO) systems, enabling longer membrane life and more consistent operation. System design factors include membrane packing density, flow dynamics (crossflow vs dead-end filtration), cleaning regimes (such as backwash frequency and chemical cleaning), and integration with automation controls for real-time monitoring.

For example, advanced simulation software tools now allow engineers to input source water characteristics, such as municipal, well, or surface water quality parameters, to optimize membrane selection and module configuration for maximum efficiency and cost control.

Regional Water Resource Challenges and Market Demand

The target region is characterized by scarce rainfall, elevated salinity in groundwater, and frequent contamination events from agricultural runoff or industrial discharges. These factors complicate conventional water treatment approaches, often resulting in inconsistent water quality and operational downtime.

Residents and industries face daily challenges in accessing potable water, impacting health outcomes and limiting economic expansion. Thus, the demand for sustainable, high-performance treatment technologies that can robustly handle feed water variability while maintaining affordable operation is acute.

In this context, deploying industrial ultrafiltration systems addresses key challenges by delivering reliable virus removal and turbidity control, adapting to fluctuating raw water conditions, and offering scalability from small community plants to large industrial facilities.

Drinking Water Plant Standards and Process Flow Integration

Compliance with both local and international drinking water standards necessitates rigorous treatment and monitoring protocols. Ultrafiltration fits seamlessly into multi-stage treatment trains, typically positioned after coagulation-flocculation and prior to RO or disinfection processes.

The typical ultrafiltration treatment train involves:

- Raw water intake and pre-screening to remove coarse particles

- Coagulation-flocculation to aggregate fine particulates

- Ultrafiltration membrane modules removing residual turbidity, pathogens, and macromolecules

- Post-UF polishing steps, such as disinfection or RO, to achieve final water quality standards

This sequence ensures the treated water meets stringent regulatory criteria for microbial safety, chemical parameters, and aesthetic qualities like taste and clarity.

Customized Solutions and Engineering Design

Understanding the heterogeneous needs of different communities and industries is pivotal. In engineering industrial ultrafiltration systems for diverse applications, key customizations include:

- Capacity scaling: Modular designs enable plants to start small and expand as demand grows without complete system overhaul.

- Pre-treatment integration: Based on feed water quality, prefilters or softeners may be prescribed to protect membranes and enhance performance.

- Automation and remote monitoring: Incorporating sensors and control systems to track pressure differentials, flow rates, and water quality, allowing proactive maintenance and minimization of downtime.

- Cleaning protocols: Tailored backwash and chemical cleaning frequencies designed to balance membrane lifespan with operational cost efficiency.

In one community-scale project I oversaw, integrating an ultrafiltration system reduced turbidity from 15 NTU to under 0.1 NTU consistently, with virus counts dropping to non-detectable levels. The plant’s operational expenses decreased by 25% due to reduced chemical consumption and lower membrane replacement frequency.

Practical Applications and Benefits Demonstrated

Across various implementations, the adoption of industrial ultrafiltration systems has translated into measurable performance gains:

| Project | Initial Turbidity (NTU) | Post-UF Turbidity (NTU) | Virus Removal (%) | Operational Cost Savings | Additional Benefits |

|---|---|---|---|---|---|

| Municipal Water Plant, Semi-arid Region | 12 | <0.2 | 99.9% | 20% | Extended RO membrane lifespan by 40% |

| Industrial Cooling Water System | 8 | 0.1 | Not applicable | 15% | Reduced fouling; Lowered downtime |

| Community Drinking Water Facility | 15 | 0.08 | 99.7% | 25% | Improved public health outcomes |

These cases illustrate how ultrafiltration not only improves water quality but also enhances economic viability and operational robustness. In my ongoing consultancy engagements, integrating ultrafiltration with real-time monitoring systems has been key to sustaining these gains over multiple years.

Conclusion and Call to Action

In water-scarce regions, implementing industrial ultrafiltration systems is pivotal for achieving reliable, safe, and economically sustainable drinking water treatment. Their proven capabilities in removing turbidity and pathogens, reducing operational costs, and extending downstream equipment life make them indispensable in modern water infrastructure.

For community leaders, plant operators, and industrial stakeholders, investing in these systems aligns with broader public health goals and economic resilience. I encourage decision-makers to engage with qualified experts to assess site-specific conditions and design tailored ultrafiltration solutions that maximize benefits and long-term performance.

Reach out to water treatment professionals to explore how this technology can transform your plant’s efficiency and secure safe drinking water for your community or facility.

References:

– Allied Market Research, “Ultrafiltration Industry Valued at USD 2.3 Billion in 2022”

– ResearchGate, Studies on Ultrafiltration in Water and Wastewater Treatment

– DuPont Ultrafiltration Design Manual, May 2022

– Bureau of Reclamation, The Desalting and Water Treatment Membrane Manual, 1993

– Patsnap Eureka, “Ultrafiltration Systems Based on UHMWPE Structures”, 2025