Wondrous Steps: RO Water Treatment Plant for Dialysis Yields Pure Water

Water is the lifeblood of dialysis treatment, crucially impacting patient safety and therapy efficacy. Among various purification methods, reverse osmosis (RO) water treatment plants for dialysis stand out as the gold standard for producing ultrapure water. This article delves deeply into the technical, operational, and practical aspects of RO systems in dialysis, providing authoritative insights combined with industry experience. Whether you are a healthcare professional, facility manager, or water treatment specialist, this guide will enhance your understanding of how these systems protect vulnerable patients and sustain clinical excellence.

1. Introduction

Dialysis water quality is perhaps the most critical, yet often overlooked, component in ensuring safe and effective renal replacement therapy for patients with kidney failure. Untreated municipal water contains various contaminants — including bacteria, endotoxins, metals, and chloramines — that the human kidney would normally filter out but are removed externally during dialysis through advanced water treatment.

Among available purification technologies, RO systems specifically designed for dialysis water have proven unmatched in efficiency and reliability. Leading providers of this technology combine decades of expertise and cutting-edge engineering to meet rigorous safety standards and evolving clinical requirements worldwide.

2. Application Background and Market Demand Analysis

The global dialysis population continues to grow, driven by aging demographics and increasing prevalence of chronic kidney disease. This growth amplifies the demand for consistent dialysis water safety and regulatory compliance. Many regions face technical challenges such as high total dissolved solids (TDS), chloramine contamination, and microbial threats in local water sources.

Patients and healthcare providers are ever more vigilant about water purity due to documented adverse events linked to waterborne contaminants. Consequently, stakeholders prioritize investment in robust water treatment plants that ensure regulatory conformity and enhanced clinical outcomes.

- Health & Safety Concerns: Patients undergoing hemodialysis are exposed to large volumes of treated water. Any compromise in water quality may cause hemolysis, allergic reactions, or chronic inflammation.

- Environmental Sustainability: Dialysis centers aim to optimize water consumption and waste, integrating energy-efficient system designs.

- Regulatory Pressure: Stringent ISO and AAMI standards mandate ultrapure water compliance, driving technological innovation.

3. Technical Principles Explained

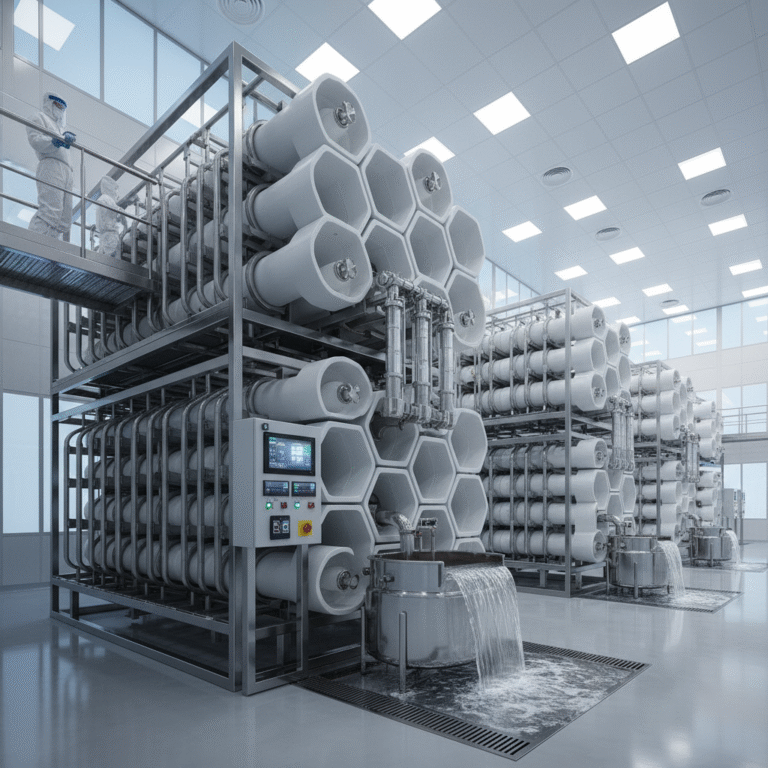

At the heart of a dialysis RO water treatment plant lies the principle of reverse osmosis: applying hydrostatic pressure to force feed water through a semipermeable membrane that selectively excludes contaminants.

| Component | Function | Effect on Water Quality |

|---|---|---|

| Pre-Treatment | Filtration, softening, activated carbon adsorption | Removes sediments, hardness ions (Ca²⁺, Mg²⁺), and chlorine/chloramines protecting RO membranes |

| RO Unit | Membrane separation via pressure-driven flow | Reduces >90% ionic contaminants, bacteria, endotoxins and organics |

| Post-Treatment & Distribution | Storage in sanitized tanks, inert piping, endotoxin filters | Prevents recontamination, ensures microbial safety and endotoxin control |

Advanced systems sometimes incorporate dual RO units in series for feedwaters with very high TDS or stringent purity demands. Additionally, heat disinfection of the water distribution loop effectively curtails biofilm formation, a recurring challenge in dialysis units.

4. Company and Product Overview

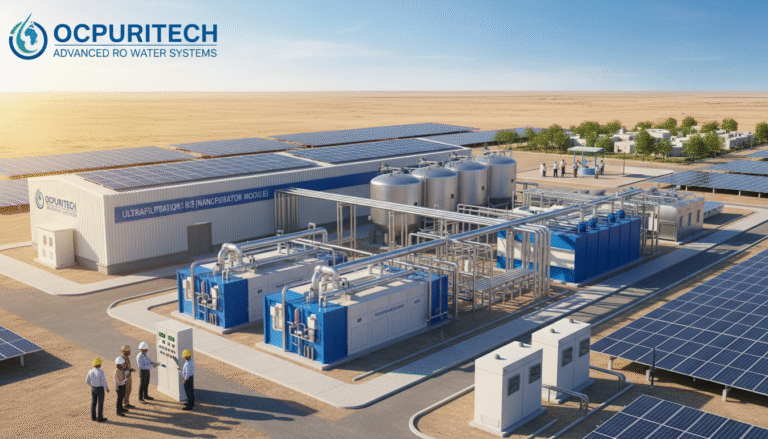

Numerous international enterprises have pioneered the evolution of dialysis water treatment plants, evolving from simple filtration setups to smart, integrated systems with automated monitoring and disinfection cycles.

- Global Footprint: Leading manufacturers distribute equipment globally, adapting designs to meet regional regulations and water quality challenges.

- Localized Innovation: Tailored modular systems offer flexibility, allowing healthcare facilities to scale and customize according to patient load and resource availability.

- Commitment to Quality: Continuous R&D investments ensure compliance with ISO 23500 series and AAMI standards, providing system durability and high uptime.

5. Product Features and Advantages

Dialysis-specific RO systems integrate a suite of advanced features designed to safeguard patient health and streamline maintenance:

- Robust Pretreatment: Multi-stage filtration protects membranes from chlorine/chloramine damage and scale formation.

- High-Efficiency Membranes: Selected for high rejection rates and long service life.

- Automated Monitoring: Continuous TDS, pressure differentials, and chloramine sensors provide real-time data and alarms.

- Smart Disinfection: Scheduled heat or chemical disinfection cycles integrated into control logic minimize bacterial contamination.

- Sustainable Design: Water recycling features and energy-saving pumps contribute to reduced operational costs.

The economic benefit is evident through increased membrane longevity, lower chemical consumption, and avoidance of costly patient complications arising from poor water quality. Environmentally, these systems demonstrate reduced chemical waste and improved resource utilization.

6. Multi-Industry Application Cases

Although developed primarily for medical use, RO water treatment plants for dialysis have found applications across diverse sectors, demonstrating their versatility and robustness.

Healthcare Facility Example

In a major urban dialysis center serving over 500 patients weekly, the installation of a dual-RO system with automated monitoring reduced microbial contamination incidents by 85%. This improvement lowered patient hospitalizations due to waterborne endotoxemia, significantly enhancing care quality.

Food & Beverage Industry

Adapted RO units ensure ultra-pure water compliant with food safety standards, used in beverage production lines where taste and safety are paramount. The reliability of these systems ensures minimal downtime during peak production.

Pharmaceutical Manufacturing

Clean water requirements in pharmaceutical formulation are stringent. RO systems modeled after dialysis iterations provide consistent ultrapure water to avoid product contamination, streamlining compliance with Good Manufacturing Practices (GMP).

7. Installation and Maintenance Guidance

Professional installation is key to guarantee system performance and longevity. Critical steps include:

- Site Assessment: Evaluate water source quality, space, and electrical requirements.

- Pre-Treatment Integration: Configure filters and softeners customized to feed water properties.

- RO Unit Setup: Ensure correct membrane orientation, pressure settings, and leak-free connections.

- Distribution Loop Commissioning: Use inert piping materials such as plastics and install endotoxin-retentive filters downstream of the RO unit.

Maintenance protocols demand routine: membrane integrity testing, chloramine monitoring twice daily, heat disinfection cycles monthly, and prompt replacement of consumables. Local technical support and training enhance operational stability and minimize unscheduled downtime.

8. Competitor Comparison and After-Sales Assurance

| Feature | Dialysis-Specific RO Systems | Generic Water Filters |

|---|---|---|

| Contaminant Removal | >90% removal including bacteria and endotoxins | Limited to particulates and chlorine |

| Regulatory Compliance | Designed to meet ISO 23500 and AAMI | No guaranteed conformity |

| Monitoring & Automation | Continuous sensors with alarms | Often manual, less frequent checks |

| Post-Treatment Options | Endotoxin-retentive filters, heat disinfection | Minimal post-treatment features |

After-sales commitments typically include warranties of membrane integrity, consumables supply assurance, remote diagnostics, and on-site technical assistance — all critical for uninterrupted clinical operations.

9. User Testimonials and Success Stories

“Since upgrading to a dialysis-grade RO plant, our clinic has seen a measurable drop in water-related complications. The real-time monitoring gives us peace of mind,” reports a clinical manager at a regional dialysis center.

Another facility director notes, “The modular system was easy to install and integrates seamlessly with our existing infrastructure. Our technicians appreciate the automated maintenance alerts, which help prevent service interruptions.”

10. Conclusion and Call to Action

The importance of safe, ultrapure dialysis water cannot be overstated. Investing in a dedicated RO water treatment plant for dialysis ensures regulatory compliance, improves patient outcomes, reduces operational risks, and supports sustainable healthcare delivery. Facilities looking to enhance dialysis safety and efficiency must prioritize modern RO systems designed around international standards.

We encourage healthcare providers, water treatment decision-makers, and clinical engineers to rigorously assess water purification needs and collaborate with trusted water system specialists to deploy solutions that safeguard patient health and elevate care standards.

Discover how the latest advancements in RO dialysis water technology can reshape your facility’s approach to renal care and water safety—taking this wondrous step today will yield pure water and healthier tomorrows.

References (Authoritative Data Sources)

- CDC – Water Use in Dialysis

- Carewater Solutions – What are the quality standards for dialysis water?

- Nipro – Dialysis Water Quality Overview

- Renal Fellow Network – Water Treatment for Hemodialysis

- Chunke Water Treatment – Reverse Osmosis System for Dialysis

- ISO 23500 series (Water Treatment for Hemodialysis)

- AAMI Standards (Association for the Advancement of Medical Instrumentation)