Introduction: Confronting Water Scarcity with Innovative Purification Technology

Water scarcity remains one of the most pressing global challenges, especially in regions facing arid climates, rapid population growth, and industrial expansion. In many parts of Africa, Asia, and the Middle East, access to safe, clean drinking water is limited, contributing to public health crises and hindering socio-economic development. Within this context, advanced water purification technologies have become indispensable tools for ensuring water security.

One standout method is reverse osmosis is a water purification technique that uses specialized semi-permeable membranes to remove contaminants, pathogens, and dissolved solids from raw water sources. This technology has transformed approaches to water treatment, making previously unusable sources safe for human consumption and industrial use.

Understanding how reverse osmosis integrates into water purification systems is crucial for public health officials, engineers, and policymakers planning sustainable water infrastructure. This article provides an in-depth exploration of reverse osmosis and allied membrane filtration technologies, emphasizing their adaptability to water-scarce regions and their undeniable impact on improving water quality and availability.

Product and Technology Overview: Reverse Osmosis and Complementary Filtration Systems

Reverse osmosis (RO) is a water purification technique that uses a high-pressure system to force water through a semi-permeable membrane, selectively removing impurities such as salts, bacteria, viruses, and organic compounds. Unlike conventional filtration, RO membranes operate at a molecular level, effectively reducing total dissolved solids (TDS) to very low levels.

Complementing RO, technologies such as ultrafiltration (UF) and electrodeionization (EDI) are often integrated into treatment trains:

- Ultrafiltration: Employs membranes with larger pore sizes than RO to remove suspended solids, colloids, and some pathogens, serving as an effective pretreatment stage.

- Electrodeionization: A chemical-free process used after RO to polish the purified water further by removing ionized species, enhancing water purity for sensitive industrial applications.

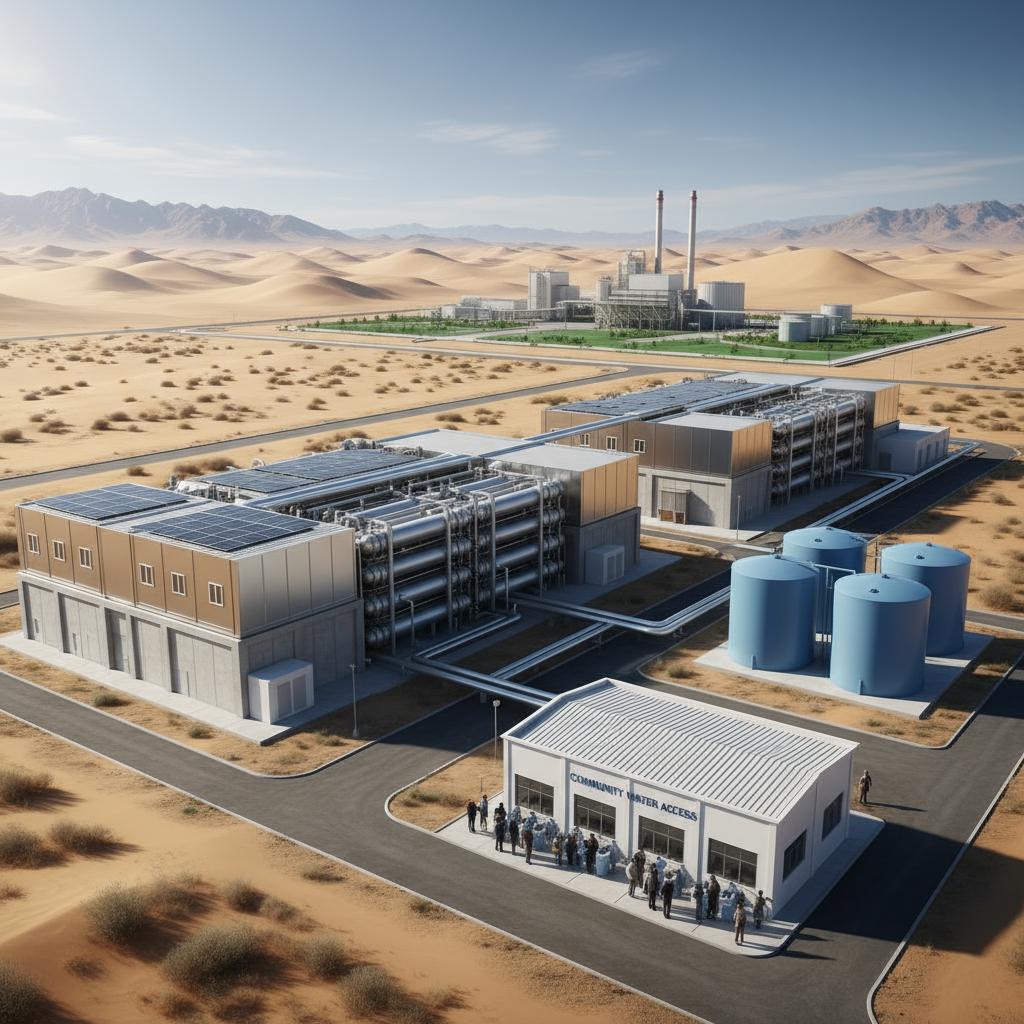

These technologies are modular and scalable, designed to suit a variety of system sizes from decentralized community water plants to large-scale industrial facilities.

Through decades of deployment, RO systems have been fine-tuned for energy efficiency and robustness. Modern membranes demonstrate high salt rejection rates (up to 99.5%) and long service lives, reducing downtime and operational costs. The addition of automated monitoring and control instruments further enhances performance and safety protocols.

Regional Water Resources Challenges and Market Demand

Regions such as the Sahel in Africa, parts of the Middle East, and arid zones in Asia confront severe limitations on freshwater availability. These often arise from low rainfall, dwindling groundwater reserves, and contamination from industrial or agricultural activities. Consequently, communities in these areas suffer from unreliable water supply and heightened risks of waterborne diseases.

Industries dependent on high-quality water—such as food processing, pharmaceuticals, and electronics manufacturing—face constant operational challenges, pushing demand for advanced purification solutions. Here, reverse osmosis techniques address both scarcity and quality concerns by enabling the use of brackish groundwater, treated wastewater, and seawater as alternative water sources.

According to recent market research, the global reverse osmosis membrane market is expected to grow from $3.73 billion in 2024 to $5.11 billion by 2029, at a compound annual growth rate (CAGR) of 6.5%. This growth is spurred by rising investments in wastewater treatment and desalination projects, underlining the mounting reliance on RO-based systems (MarketsandMarkets, 2025).

Drinking Water Plant Standards and Process Flow

Designing a drinking water plant for regions with acute water scarcity requires strict adherence to local and international standards such as WHO guidelines and EPA regulations to ensure safety and reliability. A typical treatment process incorporating reverse osmosis includes the following stages:

| Process Stage | Function | Quality Assurance |

|---|---|---|

| Raw Water Intake and Screening | Removal of large debris and preliminary contaminants. | Compliance with turbidity standards. |

| Pretreatment (Coagulation, Filtration, Softening) | Reduction of suspended solids and hardness to protect membranes. | Wastewater parameters monitored and adjusted. |

| Ultrafiltration (optional) | Removal of colloidal particles and microorganisms. | Validated removal rates per guidelines. |

| Reverse Osmosis | Primary purification removing dissolved salts and contaminants. | Membrane integrity verified; TDS reduction targets reached. |

| Post-treatment (Disinfection, pH Adjustment) | Ensures pathogen control and water stability. | Chlorine residuals kept within permissible limits. |

| Storage and Distribution | Maintains water quality until consumption. | Regular microbial testing performed. |

The integration of real-time monitoring tools helps operators manage the system proactively, ensuring continuous compliance with stringent water quality standards.

Custom Solutions and Engineering Design

Every community or industrial site presents unique challenges that necessitate tailored engineering solutions. For instance, rural villages with limited infrastructure require compact and energy-efficient RO units coupled with robust pretreatment to handle fluctuating source water quality.

In my experience working on a community water plant project serving over 10,000 residents in Northern Kenya, we implemented a hybrid pretreatment system combining sediment filtration and advanced softening to prolong membrane life. This reduced membrane fouling rates by 30%, extending the interval between replacements to over two years, thereby lowering operational expenses by 20% annually.

For larger industrial clients in arid zones of the Middle East, I have overseen designs that integrate renewable energy sources like solar photovoltaic arrays to power RO plants. Such designs not only ensure sustainable operation but also reduce the carbon footprint associated with water purification.

Moreover, incorporating advanced control systems facilitates remote monitoring and automated cleaning cycles, optimizing system reliability. Key quality assurance practices include routine membrane integrity testing, comprehensive flow monitoring, and adaptive chemical dosing for anti-scaling.

Case Studies and Impact Analysis

One notable application of reverse osmosis technology was a desalination project in coastal Tunisia that transformed brackish seawater into potable water for an expanding urban population. The system processed 5,000 cubic meters daily, achieving a 98% salt rejection rate and reducing health-related water issues by over 40% within the first year.

Similarly, a wastewater reclamation facility I advised in South Africa repurposed municipal sewage effluent using multi-stage RO treatment. The result was a reliable water source for agricultural irrigation, decreasing freshwater dependence by 25% and enabling drought resilience for growers.

These examples demonstrate how reverse osmosis is a water purification technique that uses advanced membrane filtration to not only mitigate water scarcity but also boost economic resilience through sustainable resource management.

Conclusion and Call to Action

Addressing water scarcity requires an integrated approach where advanced technologies such as reverse osmosis play a crucial role in ensuring access to safe and reliable water. The data-driven efficiencies and field-proven effectiveness of RO systems position them as cornerstone solutions in both community water supply and industrial water management.

Stakeholders are encouraged to engage with water treatment experts to explore tailored solutions that meet specific regional needs while maximizing cost-effectiveness and sustainability. Consulting early in the planning phase can significantly improve project outcomes by aligning technology choice with water quality goals and local conditions.

By embracing reverse osmosis and complementary membrane technologies, regions afflicted by water scarcity can secure a healthier future, enabling growth, reducing disease incidence, and preserving precious water resources for generations to come.

Contact our water technology advisory team today to discuss your project needs, feasibility assessments, and implementation strategies.

Data Source: MarketsandMarkets (2025), Reverse Osmosis Membrane Market Size, Industry Share Forecast.