Zealous Innovations: A Historic Turn in Industrial Potable Water Treatment

Water is the cornerstone of industrial processes across mining, food production, pharmaceuticals, cosmetics, laboratories, and municipal utilities. With ever-increasing quality demands and regulatory pressure, the evolution of industrial potable water treatment solutions marks a pivotal shift in operational efficiency and safety. In this exploration, I unpack the various facets of modern potable water treatment technologies, their economic implications, performance benchmarks, and real-world implementation strategies.

1. Product Overview

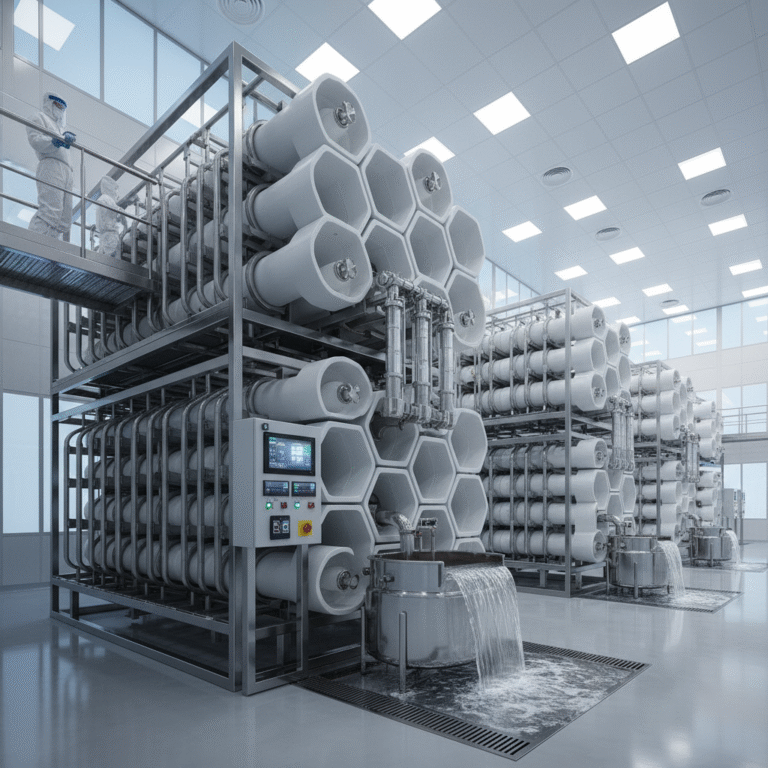

Industrial potable water treatment systems are designed to produce water that meets stringent consumption standards while accommodating diverse feedwater types — ranging from municipal supplies and well water to river, groundwater, and reclaimed water streams. They address applications such as ultrapure water for laboratories, boiler feedwater treatment, process water for pharmaceuticals, and hygiene-critical food industry usage.

These systems broadly encompass technologies such as membrane filtration units, advanced disinfection assemblies, adsorption media, and automated monitoring systems. Their core function is to reduce biological contaminants, chemical pollutants, suspended solids, turbidity, and odors to ensure water safety and compliance with health guidelines.

Industries served:

- Mining and mineral processing — managing turbidity, heavy metals, and suspended solids

- Food and beverage manufacturing — ensuring microbial safety and taste neutrality

- Pharmaceutical and cosmetics production — delivering ultrapure, contaminant-free water

- Municipal water utilities and laboratories — meeting distributed water safety and testing requirements

- Boiler water and cooling systems — controlling scaling and corrosion risks

2. Technology Principles and Key Components

The heart of advanced potable water treatment lies in combining mechanical, chemical, and biological processes optimized by automation for consistent operation:

- Membrane Separation Technologies: Systems utilize ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) to physically remove dissolved solids, microorganisms, and particles larger than 0.2 microns. RO membranes offer high rejection rates for total dissolved solids (TDS), pathogens like Giardia and Cryptosporidium, and many chemical contaminants. This core technology ensures exemplary water purity and is often coupled with pre-treatment steps to extend membrane life.

- Granular Activated Carbon (GAC): GAC adsorption is integral for volatile organic compounds (VOCs) and taste-and-odor control. It can achieve up to 99.9% reduction of targeted contaminants according to EPA data, significantly elevating water aesthetics and safety.

- Advanced Oxidation Processes (AOP) & Ultraviolet (UV) Photolysis: UV disinfection units effectively sterilize low turbidity water by destroying microorganisms and viruses, reducing reliance on chemical disinfectants, which are more commonly employed downstream to sustain residual protection in distribution systems.

- Chemical Feed Systems: Precisely controlled dosing of caustic agents, phosphates, and chlorine or alternative biocides stabilizes pH, prevents corrosion, and maintains residual disinfection.

- Automated Control & Monitoring: Integrated sensors and PLC/SCADA platforms enable real-time water quality monitoring, optimize chemical dosing, and ensure compliance with performance standards, minimizing downtime and unplanned maintenance.

Each component is selected based on source water characteristics and end-use requirements to achieve a synergistic treatment train.

3. Price Analysis

The cost structure for industrial potable water treatment equipment generally includes:

| Cost Element | Description | Typical Proportion of Total Cost |

|---|---|---|

| Base System Equipment | Membrane modules, carbon filters, UV reactors, pumps, instrumentation | 50-60% |

| Optional Add-Ons & Customization | Pre-treatment units (e.g., coagulation), post-treatment polishing, automation upgrades | 10-20% |

| Installation & Commissioning | Site preparation, integration, quality assurance | 10-15% |

| Operation & Maintenance (O&M) | Membrane replacement, media renewal, chemical costs, power consumption, labor | 10-20% annually |

In my experience, while capital expenditure can be significant upfront, systems integrated with remote monitoring and automated cleaning cycles result in 15-25% lower O&M costs over a 5-year horizon compared to legacy systems. When evaluating cost-benefit, the value of enhanced reliability, compliance avoidance penalties, and product quality assurance must be integrated.

4. Performance Specifications and Quality Assurance

Industrial potable water treatment systems must conform to rigorous performance criteria, including but not limited to:

- Turbidity reduction to below 0.3 NTU for optimal UV disinfection efficacy.

- Removal of >99% of microbiological contaminants, including Giardia cysts and Cryptosporidium oocysts.

- Total dissolved solids (TDS) reduction ranging between 80-99%, depending on membrane configuration.

- Effective reduction of specific chemical contaminants, e.g., VOCs, radon, heavy metals, in line with NSF/ANSI 53-2023 requirements.

- Adherence to material health standards (NSF/ANSI 61) to avoid secondary contamination from system components.

- Continuous real-time process monitoring with alerts for parameter deviations.

Materials selected are typically corrosion-resistant stainless steels, FDA-compliant polymers, and certified media, ensuring durability and safety throughout operational life.

5. Market and Application Scenario Analysis

Across different regions, water source qualities vary significantly, impacting system design and application:

- Mining Areas: High suspended solids and heavy metal contamination require robust pretreatment with coagulation/flocculation and membrane filtration.

- Food and Beverage Sectors: Emphasis on taste, odor removal, and zero microbial contamination; often incorporating advanced carbon filtration and UV disinfection.

- Pharmaceutical Manufacturing: Demand ultrapure water with stringent control over ionic and microbial levels; multiple-stage membrane and polishing steps are standard.

- Municipal Water Utilities: Systems designed to comply with evolving regulatory frameworks such as the EU Drinking Water Directive (2020/2184/EU), targeting emerging contaminants like endocrine disruptors and microplastics.

The adaptability of treatment trains to local water chemistry and regulatory demands is a critical factor in technology uptake and long-term operational success.

6. Case Studies From the Field

In one notable project serving a midwestern food processing facility, the integration of a membrane-based potable water system with GAC followed by UV disinfection reduced customer complaints related to off-tastes by 95% within three months. This led to downstream production quality improvements and a documented 20% reduction in rejection rates.

Another case involved a pharmaceutical manufacturer in a region relying on deep well water with high TDS and microbial load. After retrofitting with a two-stage RO system complying with NSF/ANSI 58-2023 standards, the plant achieved consistent ultrapure water output with TDS below 10 ppm and zero detected microbiological contamination, drastically cutting batch failures and regulatory audit findings.

Lastly, a municipal utility embraced a customized treatment solution integrating ion exchange with advanced oxidation processes to address emerging organic pollutants. This system consistently met EPA and WHO guidelines, reducing chemical dosing by 30% and lowering operating costs.

7. Customization Options and Service Support

Recognizing that no two water sources or industrial needs are identical, tailored customization is key to maximizing system performance. Common options include:

- Pre-treatment modules such as coagulation-flocculation systems, sedimentation tanks, or multimedia filtration depending on source water turbidity and contaminant profile.

- Post-treatment polishing units designed to adjust pH, add corrosion inhibitors, or further remove trace organics.

- Advanced automation packages supporting predictive maintenance and remote diagnostics.

- Comprehensive installation services including site surveys, structural modifications, and system integration.

- Long-term after-sales support encompassing preventive maintenance contracts, spare parts inventories, and technical training for local operators.

In my deployment experience, offering modular upgrades and strong technical service partnerships has been instrumental in achieving heightened client satisfaction and equipment longevity.

8. Manufacturer Profile and Collaborative Benefits

Leading producers of industrial potable water treatment systems hold certifications aligned with ANSI/NSF standards, EU directives, and ISO quality management frameworks. Their R&D capabilities often translate into rapid incorporation of novel technologies such as nanoengineered membranes and AI-driven process optimization.

Collaborations with such manufacturers provide clients advantages in:

- Access to cutting-edge water treatment innovations verified by rigorous testing.

- Compliance assurance through adherence to latest NSF/ANSI standards (e.g., 53-2023, 58-2023, 60-2024).

- Robust project management methodologies ensuring on-time and on-budget delivery.

- Global support networks facilitating spare part availability and technical assistance.

9. Conclusion and Investment Recommendations

The landscape of industrial potable water treatment is witnessing transformative advances driven by regulatory demands, technological breakthroughs, and operational imperatives. Deploying integrated membrane filtration blending with activated carbon adsorption and UV disinfection forms the backbone of modern systems that satisfy comprehensive safety, efficiency, and sustainability criteria.

Investors and industrial operators should consider the following strategies to optimize returns:

- Prioritize modular, scalable systems with automation to adapt to evolving water quality and production volumes.

- Evaluate total cost of ownership focusing on lifecycle O&M savings achievable through advanced control and cleaning technologies.

- Ensure suppliers hold up-to-date ANSI/NSF certifications to guarantee regulatory compliance and equipment reliability.

- Engage in early water quality assessments and pilot testing to tailor technology combinations and avoid costly post-installation adjustments.

- Leverage expert technical partnerships for service continuity and knowledge transfer.

By aligning technological rigor with strategic foresight, industries can secure safe, high-quality potable water essential for their operations while safeguarding environmental and human health.

References:

- U.S. Environmental Protection Agency (EPA) – Overview of Drinking Water Treatment Technologies (2025)

- American National Standards Institute (ANSI) – NSF/ANSI Drinking Water Treatment Standards (2023-2024)

- World Health Organization (WHO) – Drinking-Water Quality Guidelines (2023)

- European Union Drinking Water Directive (2020/2184/EU)