Introduction to Industrial Well Water Treatment and Its Significance

In an era where industrial operations increasingly rely on sustainable and efficient water management, well water treatment has become a critical pillar for ensuring process reliability, environmental compliance, and product quality. Industrial well water, often drawn from underground aquifers, carries unique challenges including variable mineral content, microbial contamination, and chemical impurities. Proper treatment transforms this raw resource into process-grade water that safeguards equipment longevity and supports environmental stewardship.

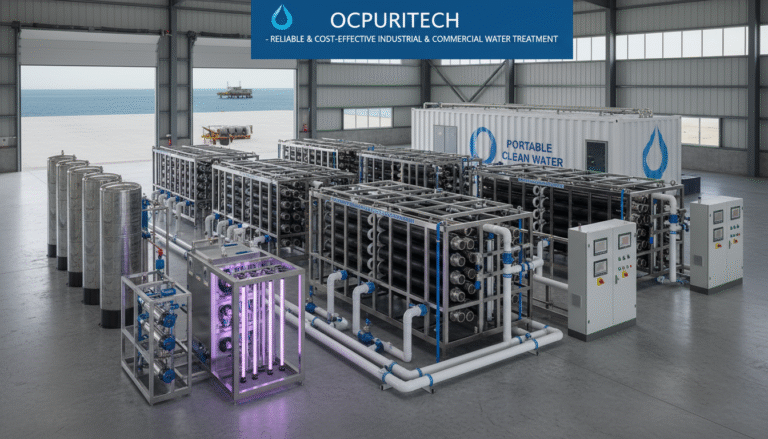

Our company stands as a leading manufacturer and developer of advanced well water treatment technologies, deeply committed to elevating industry standards through innovation and rigorous quality control. By combining decades of research with cutting-edge production capabilities, we address the evolving demands of industrial clients across diverse sectors. Environmental responsibility is central to our mission, underpinning every system design and deployment to reduce pollution and conserve resources.

Comprehensive Product Portfolio for Tailored Well Water Treatment

Reverse Osmosis (RO) Systems

Our reverse osmosis systems represent the core of high-purity water production from well sources. Utilizing semipermeable membranes with pore sizes in the range of 0.0001 microns, they efficiently remove dissolved salts, organic compounds, and microorganisms. Operating at pressures between 150 to 600 psi, these systems achieve removal rates exceeding 98% for total dissolved solids (TDS), ensuring compliance with stringent process water criteria.

Technical Specifications:

- Capacity ranges: 5 to 100+ cubic meters per hour

- Recovery rate: 75% to 85%

- Energy consumption: 3-6 kWh/m³ depending on feedwater quality

- Pre-treatment integration capability with ultrafiltration and softening

These systems are extensively utilized in semiconductor fabrication, pharmaceutical manufacturing, and food & beverage industries where ultrapure water is mandatory.

Ultrafiltration (UF) Systems

Ultrafiltration modules provide a robust barrier against suspended solids, colloids, and macromolecules with membrane pore sizes typically ranging from 0.01 to 0.1 microns. Positioned as a pre-treatment step ahead of reverse osmosis or as a standalone clarification stage, UF systems enhance feedwater quality, prolong RO membrane life, and reduce chemical usage.

Key Performance Indicators:

- Flux rate: 100-300 LMH (liters per square meter per hour)

- Operating pressure: 1 to 4 bar

- Recovery rate: Up to 90%

- Automated backwash and chemical cleaning protocols for low downtime

Industries such as textile dyeing, pulp and paper, and power generation leverage UF technology to improve water reuse rates and meet effluent discharge standards.

Electrodeionization (EDI) Systems

To achieve ultrapure water standards without chemical regenerants, our electrodeionization units combine ion exchange resins with ion-selective membranes under direct current electricity. This continuous process removes ionic contaminants including silica, bicarbonates, and nitrates, yielding resistivity values approaching 18.2 MΩ·cm.

System Highlights:

- Feedwater TDS limit: <10 mg/L

- Electrical consumption: ≤ 2 kWh/m³

- No chemical regenerants required, minimizing environmental impacts

- Compact footprint with modular scalability

Ideal for electronics manufacturing, pharmaceutical R&D labs, and high-purity steam generation, these systems represent next-generation ion removal technology.

Pre-Treatment and Water Softening Units

Pre-treatment is indispensable for protecting membrane integrity and optimizing process efficiency. Our comprehensive range of multimedia filters, activated carbon units, and water softeners significantly reduce suspended solids, chlorine, and hardness ions.

Core Features:

- Multimedia filtration down to 5 microns particulate size

- Activated carbon adsorption for chloramines and organic compounds

- Cation exchange or salt-free softening for calcium and magnesium removal

- Automated regeneration and backwash systems for operational continuity

These modules find broad applicability across metal finishing, chemical processing, and food industries where feedwater conditioning is critical.

Innovations and Competitive Advantages

Our continuous investment in R&D has yielded several industry-leading enhancements that translate into tangible client benefits. Notably, our proprietary membrane fabrication techniques improve fouling resistance by 20%, and energy recovery devices integrated with RO units reduce specific energy consumption by up to 15% compared with conventional setups.

The following comparison table outlines how our solutions outperform traditional alternatives:

| Parameter | Traditional Systems | Our Advanced Solutions | Benefit |

|---|---|---|---|

| Membrane Fouling Rate | High (8–12 months lifespan) | Low (12–18 months lifespan) | 50% longer membrane life |

| Energy Consumption (kWh/m³) | 5.5 – 7 | 4.5 – 6 | ~15% energy savings |

| Chemical Usage for Cleaning | Regular & frequent | Reduced and optimized | Lower operational costs |

| System Automation Level | Manual or semi-automatic | Fully automated with remote monitoring | Improved system uptime |

From my experience leading the deployment of a large-scale RO system at a Southeast Asian textile manufacturer, the integrated energy recovery led to a 12% reduction in electricity costs annually, while membrane longevity improvements cut replacement frequency by 30%, significantly reducing downtime and maintenance expenses.

Industry Position and Market Outlook

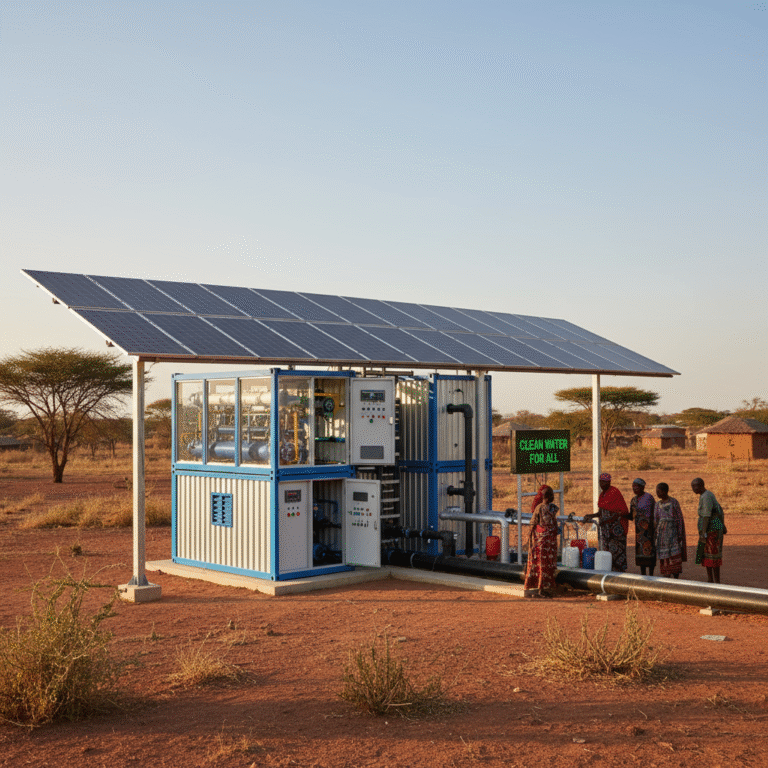

Our company operates strategically across key emerging markets in Africa, Southeast Asia, South America, and Asia. These regions experience rapid industrialization alongside increasing water scarcity, demanding robust well water treatment solutions aligned with regulatory compliance and sustainable development goals.

According to global water treatment market reports, demand for advanced industrial water treatment equipment in these regions is forecasted to grow at annual rates exceeding 7% over the next five years, driven by expanding manufacturing sectors and environmental legislation tightening.

Regional participation in standard-setting bodies and active collaboration with local governments further underscore our commitment to delivering cutting-edge, compliant solutions that fulfill evolving market needs.

Manufacturing and R&D Excellence

Our production facilities employ state-of-the-art automation and precision manufacturing equipment, ensuring consistent quality and scalability. Rigorous quality assurance protocols — including ISO 9001 and industry-specific certifications — govern every stage from component sourcing to final testing.

Complementing manufacturing is a dedicated R&D team composed of chemical engineers, process experts, and material scientists who actively collaborate with academic institutions and industry consortia. This synergy accelerates innovation cycles and validates performance under diverse field conditions.

In one example, our recent pilot incorporating novel nanofiltration membranes achieved 25% higher contaminant rejection rates with reduced fouling in pilot tests at a South American mining facility, promising next-generation upgrades to our product line.

Key Client Success Stories

Several industrial clients across continents have leveraged our well water treatment systems to achieve transformative outcomes:

- Power Generation Plant, Africa: Implementation of a combined ultrafiltration and RO system improved boiler feedwater quality, reducing blowdown rates by 18% and prolonging turbine maintenance intervals by six months.

- Food Processing Facility, Southeast Asia: Adoption of water softening and EDI technologies eliminated scaling in heat exchangers, cutting cleaning downtime by 40% and enhancing product consistency.

- Textile Manufacturer, South America: Integration of modular pre-treatment with UF and RO reduced freshwater consumption by 30% through effective water reuse, aligning with corporate sustainability targets and lowering operational costs.

These experiences confirm the versatility and reliability of our systems across different industrial environments.

Commitment to Environmental Sustainability

Sustainability is embedded in every facet of our well water treatment products. From minimizing chemical additives to energy optimization and waste reduction, our solutions help clients meet environmental regulations and corporate social responsibility goals.

Our products are designed for recyclability and low ecological footprints. For instance, the adoption of chemical-free electrodeionization cuts hazardous waste generation significantly. Additionally, energy-efficient pumps and motors reduce greenhouse gas emissions associated with operations.

In one project supporting a South African mining operation, the deployment of our advanced water recovery system enabled water reuse rates exceeding 85%, dramatically lessening freshwater withdrawals from sensitive groundwater reserves.

Contact Us for Tailored Well Water Treatment Solutions

We invite industrial operators and technical decision-makers interested in elevating their water management systems to consult with our engineering experts. Our team provides comprehensive assessments, custom design, and full lifecycle support to maximize your investment returns and operational resilience.

Reach out to us via phone, email, or online inquiry forms to discuss your project requirements and start the journey toward sustainable, high-performance well water treatment.

References

- CEIC Data – China Purchasing Price Index: Building Material, 2024

- HROne – Labor Cost Comparison China vs Southeast Asia, 2025

- PwC CEO Survey 2024

- Global Industrial Water Treatment Market Reports, 2023-2025