Zesty Insights: Elevate Water Treatment for House with Advanced RO Systems

1. Introduction: Understanding Commercial Reverse Osmosis (RO) Water Treatment Systems

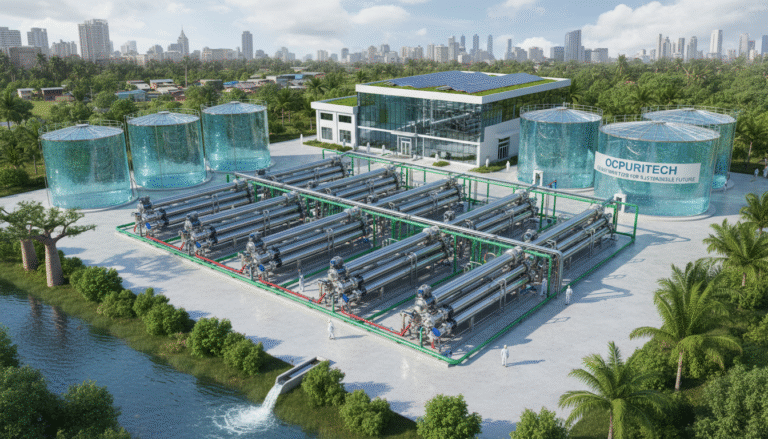

Water treatment is a cornerstone of modern industrial and residential sustainability efforts. Among various technologies, reverse osmosis (RO) has emerged as a leading method for purifying water by removing dissolved contaminants with high efficiency. Commercial-scale RO systems exemplify a critical evolution in water treatment, offering robust capacity suited to diverse industrial sectors. These systems deliver purified water essential for manufacturing, healthcare, food production, and residential applications alike.

In today’s context, where water quality directly impacts health, productivity, and environmental compliance, understanding RO systems’ significance and applications is vital. This article provides a comprehensive insight into commercial RO water treatment equipment, focusing on performance, operational mechanisms, key components, and practical industry usage.

2. Equipment Overview and Performance Advantages

Commercial RO systems are engineered to efficiently treat large water volumes by forcing feedwater through semipermeable membranes, thereby extracting impurities such as bacteria, heavy metals, pesticides, and dissolved solids. These systems typically feature high recovery rates—often above 75%—and can handle feedwater with varying qualities, including brackish or slightly saline sources.

Performance-wise, advanced RO units provide:

- High contaminant rejection rates: Effective removal of >98% of total dissolved solids (TDS) and microbial contaminants.

- Energy-efficient operations: Integration of optimized high-pressure pumps and energy recovery devices reduces operational expenses.

- Modular scalability: Customizable configurations accommodate capacity demands from a few hundred liters per hour to multiple cubic meters daily.

Market data underscores these advantages. According to Grand View Research, in 2021, the global RO segment constituted over 38% of the home water purification market’s total revenue, dominating due to its broad efficacy. This leadership status remains robust in commercial water treatment systems as well.

3. Process Flow of Commercial RO Water Treatment Systems

The operation of commercial RO systems can be broken down into several key stages:

| Stage | Description | Key Process Steps |

|---|---|---|

| Pre-treatment | Removal of suspended solids, chlorine, and hardness to protect membranes | Multimedia filtration → Activated carbon filtration → Water softening |

| High-Pressure Pumping | Feedwater is pressurized to overcome osmotic pressure for membrane permeation | Feedwater pumped at 8-30 bar (depending on feedwater salinity) |

| RO Membrane Filtration | Separation of contaminants via semipermeable membranes | Water passes through membranes → Rejects concentrated brine → Collects purified permeate |

| Post-treatment | Conditioning of purified water for consumption or industrial use | UV sterilization, pH adjustment, and final polishing if needed |

This systematic workflow ensures comprehensive contaminant reduction while maintaining operational efficiency and membrane longevity.

4. Key Component Breakdown

Understanding the key constituents of a commercial RO system is essential for appreciating its capabilities.

- Multimedia Filters: These remove large suspended solids and sediment, protecting downstream components. Typically layered media includes sand, anthracite, and garnet.

- Activated Carbon Filters: Crucial for adsorbing chlorine, pesticides, and organic compounds that can damage RO membranes or degrade water taste.

- Water Softeners: These ion-exchange units reduce hardness (calcium and magnesium), curbing scale formation on membranes.

- High-Pressure Pumps: Regulate pressure to optimize permeate flow, with energy-efficient models minimizing power consumption.

- RO Membranes: Core filtering elements made from thin-film composite materials, designed specifically for the feedwater type (e.g., brackish or seawater).

Each part plays a vital role in system uptime, filtration efficacy, and cost-effectiveness.

5. Membrane Technology: Features and Maintenance Recommendations

Membrane technology remains the heart of RO systems. Various membranes—such as thin-film composite (TFC) or cellulose acetate—offer different performance profiles:

- TFC membranes: Exhibit high salt rejection (>98%), robust chemical resistance, and operational flexibility.

- Cellulose acetate membranes: Less tolerant to chlorine but simpler to maintain in low-fouling scenarios.

Maintenance best practices include routine flushing, anti-scalant dosing, and periodic chemical cleaning based on feedwater analysis. Replacement frequency typically ranges between 2-5 years depending on usage intensity and water quality.

6. Advanced Post-Treatment Applications

Post-treatment technologies enhance water quality to meet stringent industry and safety standards. Common methods include:

- Mixed Bed Deionization: Achieves ultra-pure water by removing ionized impurities post-RO.

- Electrodeionization (EDI): Continuous regeneration technology that removes residual ionic contaminants without chemicals.

- UV Sterilization: Effectively destroys microorganisms invisible to membranes, ensuring microbiological safety.

These treatments guarantee water suitability for sensitive applications like pharmaceuticals, microelectronics manufacturing, and high-end residential use.

7. Industry Use Case Examples

Through my professional experience over a decade, I’ve observed multiple successful RO system deployments:

- Food & Beverage Sector: In a mid-sized beverage bottling plant, introducing an RO system reduced organic contaminants by 99%, resulting in extended product shelf life and compliance with FDA standards.

- Pharmaceutical Manufacturing: An RO system integrated with EDI units provided ultra-pure water essential for injection-grade formulations, significantly reducing downtime due to water quality issues.

- Textile Industry: Case study in a dyeing factory where RO treatment cut water hardness by 85%, thereby improving dye uptake and fabric quality while lowering chemical usage.

- Hospitality Sector: Installation of RO units in luxury hotels led to improved drinking water taste and safety, enhancing guest satisfaction and reducing bottled water consumption.

8. Factors Influencing Pricing and Investment Value

Pricing of RO systems depends on various factors:

| Pricing Factor | Impact Explanation | Investment Considerations |

|---|---|---|

| Component Quality | Durable membranes, stainless steel pressure vessels, advanced pumps increase upfront cost but enhance longevity. | Higher initial investment offsets maintenance and replacement frequency costs. |

| Customization Level | Tailoring system for specific feedwater or industry demands raises engineering complexity. | Ensures operational efficiency and compliance with sector regulations. |

| Operational Expenses | Energy consumption, chemical dosing, membrane replacement, and labor impact total cost of ownership. | Advanced energy recovery devices can reduce long-term expenses. |

| Financing & Support Services | Payment plans and inclusion of maintenance contracts influence affordability and risk management. | Enables better budget control and reliability assurance. |

9. Installation and After-sales Support Overview

Complete installation services ensure seamless integration of RO systems. Experienced technicians conduct site assessments, offer pre-installation guidance such as plumbing adjustments, and perform system commissioning.

Training sessions empower operators with routine operational skills and troubleshooting know-how. After purchase, dependable customer support is essential, including regular preventive maintenance visits, remote diagnostics, and spare parts availability.

10. Maintenance Strategies and Troubleshooting Tips

Consistent maintenance guarantees system longevity and optimal water quality. Recommended practices involve:

- Regular cleaning of pre-filters and activated carbon units to prevent clogging.

- Monitoring differential pressure to detect fouling early.

- Periodic chemical cleaning of membranes with appropriate agents based on fouling type.

- Routine checks on high-pressure pump performance and electrical systems.

Common issues such as pressure drops, diminished permeate flow, or taste alterations often trace back to membrane fouling or pre-treatment inefficiencies and require prompt attention.

11. Manufacturer Profiles and Market Positioning

Leading manufacturers of commercial RO equipment maintain rigorous quality control, secure international certifications (e.g., ISO, NSF), and invest heavily in R&D for membrane and pump innovations.

Market strategies focus on delivering scalable solutions tailored to regional water challenges and customer sectors. Manufacturers often provide turnkey services from system design to post-sale maintenance, reinforcing trust and long-term partnerships.

12. Conclusion: Making Informed Choices for Advanced RO Water Treatment

Investing in advanced commercial reverse osmosis systems is paramount in achieving superior water quality, operational efficiency, and regulatory compliance. Their proven effectiveness in removing a wide range of contaminants makes RO systems a pivotal technology for both industrial and high-end residential water treatment for house applications.

By integrating state-of-the-art membranes, efficient pumps, and comprehensive post-treatment stages, these systems deliver unmatched purity and reliability. Prospective users should assess their specific water quality challenges, operational goals, and budget constraints to select the ideal RO system.

For those seeking sustainable and high-performing water purification solutions, embracing advanced commercial RO technology translates into long-term cost savings, regulatory adherence, and enhanced water safety.

References and Data Sources

- Grand View Research, “Home Water Filtration Unit Market Size Analysis Report, 2030”

- Grand View Research, “Water Treatment Systems Market Size, Share Report 2030”

- Grand View Research, “North America Home Water Filtration Unit Market Report, 2030”

These reports collectively highlight the projected compound annual growth rates, market dominance of RO systems, and their superior contaminant removal efficacy, forming a robust foundation for the analysis provided.