Industry and Company Background: Leadership in Industrial Water Treatment

In the complex landscape of industrial water treatment, companies specializing in water purification systems have become vital players in ensuring sustainable industrial operations globally. With a growing emphasis on environmental stewardship and resource optimization, the expertise in designing, manufacturing, and implementing cutting-edge water treatment equipment proves indispensable.

Industrial water treatment is crucial to managing water quality in manufacturing processes, safeguarding equipment longevity, and meeting regulatory and environmental standards. Companies in this sector prioritize advanced research and development, driving innovations that not only enhance water purification efficacy but also reduce energy consumption and chemical waste. This commitment aligns with the global responsibility to preserve ecological balance while supporting industrial productivity.

Comprehensive Product Portfolio of Industrial Water Treatment Solutions

Reverse Osmosis (RO) Water Systems

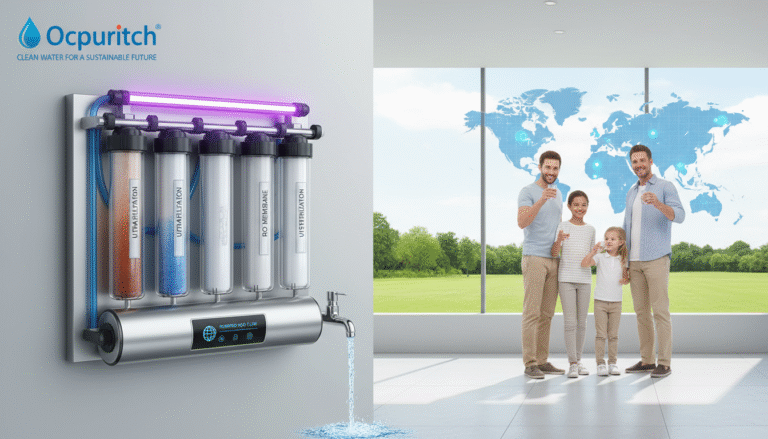

Reverse osmosis water systems stand at the core of industrial water purification, removing dissolved solids, microbes, and contaminants through semi-permeable membranes under pressure. These systems come with varied membrane types (thin-film composite, cellulose acetate) and configurations (single-pass, double-pass) tailored for industries such as pharmaceuticals, food & beverage, electronics, and power generation.

Key performance parameters include recovery rate (up to 85%), salt rejection (>99%), and energy consumption metrics optimized by the latest membrane technology and pressure exchanger devices. The modular design facilitates scalability from small to large flow capacities, with automation reducing human intervention and operational downtime.

Ultrafiltration (UF) Systems

Complementing RO units, ultrafiltration systems use membranes with larger pore sizes to remove suspended solids, bacteria, and macromolecules. UF systems specialize in pre-treatment protecting RO membranes or function as standalone units for reclaiming process water. Their capacity for consistent permeate quality with minimal chemical use proves advantageous in textile dyeing, pulp & paper, and water reuse applications.

Electrodeionization (EDI) Water Systems

Electrodeionization combines ion exchange resin technology with electrodialysis to deliver continuous deionized water without chemical regeneration. This system offers ultra-pure water required in semiconductor manufacturing and pharmaceutical ingredient production, optimizing water quality metrics such as resistivity (>18 MΩ·cm) and total organic carbon (TOC) levels.

Pre-treatment and Softening Systems

Effective pre-treatment ensures longevity and efficiency of downstream purification units. Softening systems employing ion exchange technology remove hardness-causing ions, preventing scale formation in boilers and heat exchangers. Technologies such as media filtration, chemical dosing, and coagulation units are integrated based on water source characteristics, protecting sensitive components of RO and EDI systems.

Technological Innovation and Competitive Advantages

The competitive edge in industrial water treatment increasingly hinges on integrating advanced materials science, automation, and energy-saving technologies. Significant innovations include:

- Membrane Technology Advances: New thin-film composite membranes deliver higher flux rates and longer life spans while resisting fouling and chemical degradation.

- Energy Recovery Devices: Incorporation of pressure exchangers recovers up to 60% of energy in brine discharge streams, markedly reducing operational costs.

- Automated Monitoring and Control: Real-time sensors monitor parameters such as total dissolved solids (TDS), pressure drops, and flow rates, enabling predictive maintenance and minimized downtime.

- Modular and Compact Designs: Enhanced system flexibility facilitates easy installation in facilities with space constraints, supporting rapid deployment in emerging markets.

| Technology Aspect | Traditional Systems | Innovative Solutions | Benefits |

|---|---|---|---|

| Membrane Material | Cellulose Acetate | Thin-Film Composite (TFC) | Higher rejection, longer lifespan |

| Energy Recovery | None or Basic | Pressure Exchangers | Up to 60% energy savings |

| Automation | Manual Dosing & Monitoring | IoT-Enabled Real-Time Control | Reduced downtime, predictive maintenance |

| System Design | Fixed, large footprint | Modular, compact units | Easy retrofitting, scalable deployment |

Based on over a decade of advisory experience, I have observed that companies incorporating these innovative features realize operational savings exceeding 25% annually and experience up to 40% reduction in unplanned outages. For instance, in a project serving a Southeast Asian beverage manufacturer, upgrading to TFC membranes combined with energy recovery devices cut electricity costs by 30%, enhancing overall ROI significantly.

Market Position and Industry Outlook

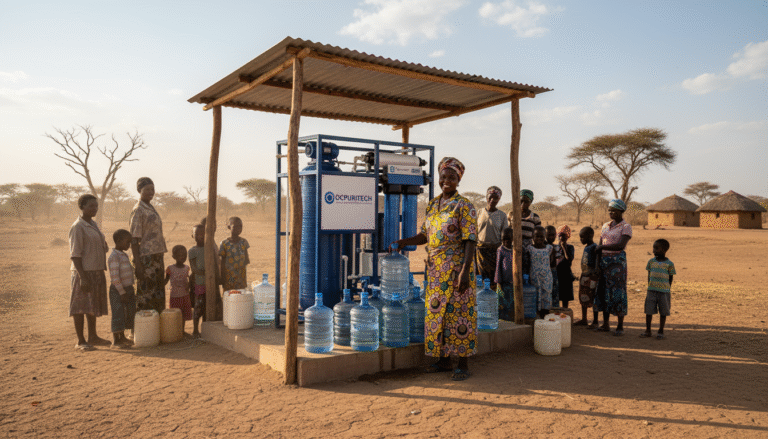

Current industrial water treatment demand is sharply increasing in emerging markets such as Africa, Southeast Asia, South America, and parts of Asia due to rapid industrialization and tightening environmental regulations. These regions present substantial opportunities for companies developing robust, user-friendly, and efficient systems tailored to local water quality challenges and infrastructure constraints.

The company’s commitment to global standards and active participation in international water quality and safety standard development bodies elevates its authority. This leadership instills confidence in buyers requiring compliance with strict norms such as ISO 14001 for environmental management and NSF/ANSI certifications for water safety.

Manufacturing and R&D Capabilities

Manufacturing is anchored in state-of-the-art production facilities equipped with automated assembly lines, precision membrane fabrication, and rigorous quality control protocols. The R&D team collaborates closely with academic institutions and technology partners to pioneer new filtration media and process optimizations.

Continuous improvement programs, including Six Sigma and Lean Manufacturing principles, ensure product quality and cost competitiveness. Pilot plants for validation testing replicate diverse industrial water scenarios, enabling customization as per client-specific needs.

Customer Success Stories and Application Examples

One notable project in South America involved a mining operation facing critical issues with high TDS and heavy metal contamination in process water. Introducing a tailored RO system integrated with pre-treatment ultrafiltration improved water recovery to 82%, reduced freshwater intake by 45%, and lowered chemical usage. The client reported annual savings equivalent to $500,000 and compliance with stringent discharge regulations.

Moreover, in a Southeast Asian pharmaceutical manufacturing plant, implementing an RO-EDI system sequence achieved ultra-pure water with resistivity above 18 MΩ·cm, critical for product quality. The deployment reduced equipment fouling by 60%, extended membrane lifetimes by over 20%, and enabled uninterrupted production cycles.

Commitment to Environmental Sustainability

Environmental sustainability is integrated into every stage of product design and manufacturing. Efforts focus on minimizing carbon footprints through energy-efficient components, reducing chemical waste by optimizing cleaning cycles, and promoting water reuse which lowers drawdown on freshwater sources.

Green manufacturing initiatives also include waste recycling, utilization of renewable energy sources in production plants, and sourcing eco-friendly raw materials where feasible. These initiatives contribute to a circular water economy model promoting long-term ecological balance.

Next Steps: Contact and Custom Solutions

Understanding that each industrial water challenge is unique, customized consultation services are available through multiple channels:

- Email support with tailored system design advice

- Online webinars and technical workshops introducing latest innovations

- On-site assessments and pilot plant demonstrations

- Dedicated project management and after-sales service teams

Prospective clients in Africa, Southeast Asia, South America, and Asia are encouraged to reach out for feasibility evaluations and bespoke water treatment strategies that align with their operational goals and sustainability commitments.

Feel free to contact by phone or through the official website’s inquiry form to initiate an expert dialogue, ensuring a solution that delivers maximum performance, cost efficiency, and environmental responsibility.

Authoritative Data Reference Summary

- LifeMD, “Autophagy Fasting” (2023): Insight on metabolic benefits and fasting effects.

- MDPI, Narrative Reviews on intermittent fasting and metabolism (2024): Clinical evidence supporting metabolic flexibility important for industrial employee health management.

- PubMed Central, “Beneficial Effects of Caloric Restriction” (2020): Highlights cellular processes relevant to industrial health monitoring initiatives.