The global challenge of water scarcity and quality degradation underscores the critical role of effective water treatment. From burgeoning industries to growing urban populations, the demand for clean, safe water is ever-increasing, making investments in robust water treatment solutions imperative. Ocpuritech, with its 14 years of experience since its establishment in 2011, stands dedicated to providing high-quality, cost-effective water treatment solutions. Our vision is simple yet profound: “We hope everyone in the world can drink clean and pure water.” We specialize in industrial, commercial, and household water purification, including comprehensive bottle water filling lines.

This guide aims to help businesses and individuals make informed decisions when investing in the best water treatment machinery. We will delve into technical details, economic considerations, and long-term benefits to ensure you achieve clean, pure water and optimal return on investment (ROI).

Whether you are a water treatment wholesaler, a project customer in pure or ultrapure water, a drinking water provider, or an international e-commerce buyer, this article will provide you with comprehensive insights, from understanding various product types to crafting sound investment advice.

Product Overview: Exploring Diverse Water Treatment Machinery

The spectrum of water treatment machinery is vast, designed to address various contaminants and water quality requirements across different sectors. Understanding these diverse systems is the first step towards identifying the best water treatment machinery for your specific needs.

1.1 Types and Functions of Industrial Water Treatment Equipment

Modern industrial processes demand precise water quality, which often necessitates specialized equipment. Here’s a breakdown of common types:

- Remote Control Reverse Osmosis (RO) System: Ideal for producing high-purity water, these systems are a cornerstone of many industrial applications. Their ability to remove dissolved solids, salts, and other impurities makes them indispensable.

- Brackish Water RO System: Specifically designed for areas with moderately saline water sources, these units efficiently convert brackish water into potable or process water, expanding water resource options.

- Seawater Desalination System: Critical for coastal regions and areas facing severe freshwater scarcity, these robust systems transform seawater into freshwater, providing a reliable supply.

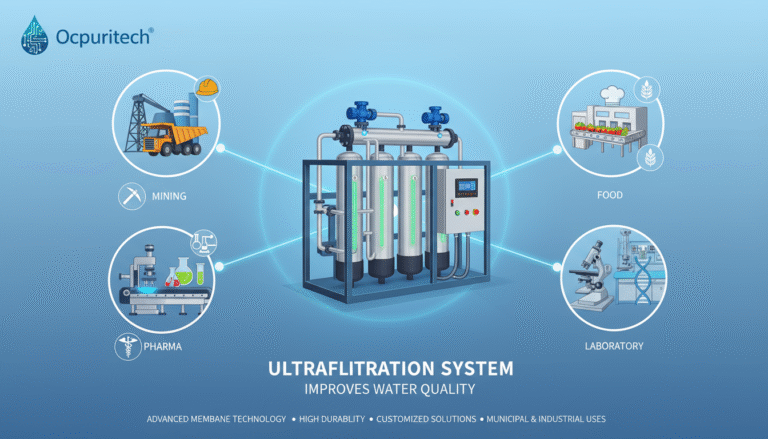

- Ultrafiltration (UF) System: UF systems excel at removing suspended solids, bacteria, viruses, and other macromolecules from water, often serving as an effective pre-treatment for RO systems or as a standalone purification method.

- Nanofiltration (NF) Systems: These systems offer selective removal capabilities, effectively filtering out divalent ions, organic matter, and some smaller particles, making them suitable for water softening or color removal.

- EDI Ultrapure Water System: For applications demanding extremely high water purity, such as in semiconductor manufacturing or pharmaceutical production, Electrodeionization (EDI) systems continuously deionize water without the need for chemical regeneration.

- Pretreatment Systems: Essential for protecting downstream equipment and ensuring overall system efficiency, pretreatment includes Sand Filters (to remove suspended solids), Carbon Filters (for chlorine and organic matter removal), and Softeners (to reduce water hardness).

1.2 Applications Across Various Industries

The versatility of water treatment machinery allows for its application across a broad spectrum of industries, each with unique water quality requirements:

- Mining & Industrial Processing: Water is critical for boiler feed, cooling, and various process stages. Treated water reduces scaling, corrosion, and operational costs.

- Food Processing & Beverages: Ensuring the quality and safety of products, from ingredient water to rinse water, is paramount. My experience with beverage and ice-making factories has shown that consistent water quality directly impacts taste and shelf life.

- Pharmaceutical & Cosmetics: These industries require water of exceptional purity for critical processes, including formulation, cleaning, and sanitization, often relying on EDI ultrapure water systems.

- Laboratories & Healthcare: High-purity water is indispensable for research, diagnostics, and medical applications, where even slight contamination can skew results.

- Agriculture: Treated water can improve crop yields and livestock health by reducing harmful minerals and contaminants in irrigation and drinking water.

- Municipal & Everyday Use: From providing safe drinking water for communities to supplying schools, governments, and hospitals, water treatment ensures public health and well-being.

- Recycled Water applications: Increasingly, industries are turning to advanced treatment to enable the reuse of wastewater, conserving fresh water resources.

Technical Principles & Key Components: The Heart of Effective Treatment

Behind every efficient water treatment system lies a blend of sophisticated technical principles and precisely engineered components. Understanding these aspects is crucial for appreciating what makes the best water treatment machinery truly effective.

2.1 Advanced Membrane Separation Technologies Explained

Membrane technologies represent the vanguard of water purification, offering unparalleled contaminant removal. Recent advancements in these technologies, including microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO), have become essential for industrial wastewater treatment due to their high contaminant removal efficiency and resource sustainability.

- Reverse Osmosis (RO): This process uses a semi-permeable membrane to remove ions, molecules, and larger particles from drinking water. Simply put, pressure forces the water through the membrane, leaving contaminants behind. This method is highly effective for desalination and producing high-purity industrial water.

- Ultrafiltration (UF) & Nanofiltration (NF): UF membranes have larger pores than NF, removing suspended solids, colloids, and bacteria. NF membranes, with smaller pores, selectively remove divalent ions and larger organic molecules, offering a middle ground between UF and RO in terms of separation capability. My practical experience indicates that UF is often an excellent pre-treatment for RO systems, protecting the more delicate RO membranes.

- Electrodeionization (EDI): EDI combines ion-exchange resin and electricity to continuously deionize water without the need for chemical regeneration. This makes it a preferred method for producing ultrapure water in environmentally sensitive applications. The success of membrane technologies like RO and NF continues to evolve toward better contaminant removal and operational sustainability, with comprehensive capabilities and research highlights shown in continuous advancements of membrane technologies.

2.2 Automation and Control Systems

The efficiency and reliability of modern water treatment machinery are significantly enhanced by advanced automation. Many Ocpuritech Remote Control RO systems, for instance, utilize PLC-based control panels, offering:

- Remote Monitoring: Operators can oversee system performance from anywhere, reducing the need for constant on-site presence.

- Sensors and Alarms: Real-time data on parameters like flow rate, pressure, and water quality triggers alarms for immediate attention, preventing potential issues.

- Data Logging: Performance data is recorded, enabling trend analysis, predictive maintenance, and optimization strategies.

This level of automation ensures optimal performance, minimizes downtime, and reduces operational costs.

2.3 Critical System Components

The effectiveness and durability of water treatment machinery largely depend on the quality and design of its individual components:

- Membranes: The heart of RO, UF, and NF systems. Their types (e.g., polyamide, cellulose acetate), materials, and longevity are critical. High-quality membranes are essential for consistent performance.

- Pumps: High-pressure pumps are required for RO systems, while booster pumps are used in other configurations. Reliability and energy efficiency are key.

- Valves: Control flow and pressure throughout the system. Durable, corrosion-resistant valves are vital for safe operation.

- Pressure Vessels: House the membranes, designed to withstand high operating pressures.

- Filtration Media: Sand, activated carbon, and ion-exchange resins are used in pretreatment and polishing stages.

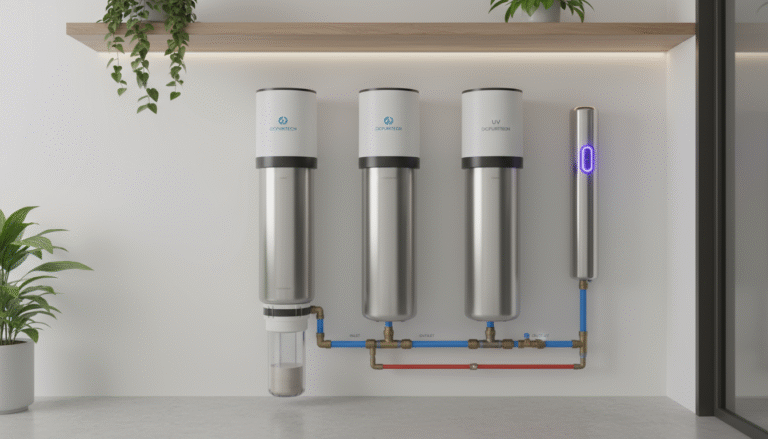

- UV Sterilizers: Essential for disinfection, ensuring microbiological control as a post-treatment step.

- Dosing Systems: Accurately inject chemicals (e.g., antiscalants, pH adjusters) to optimize treatment processes or for disinfection purposes.

- Materials of Construction: Components must be resistant to corrosion and compatible with the water being treated. Stainless steel (304/316), FRP (fiberglass reinforced plastic), and PVC are common choices, selected based on application and water chemistry.

Decoding Pricing: Investment vs. Long-Term Value

Investing in the best water treatment machinery is not merely about the upfront purchase price; it’s about understanding the total cost of ownership and the long-term value it brings. This often includes initial costs, operational expenses, and the projected return on investment.

3.1 Price Composition of Water Treatment Machinery

Several factors contribute to the overall cost of a water treatment system:

- Basic System Costs: This includes the core filtration units, pumps, and control systems. The complexity and capacity of these components largely dictate the baseline price.

- Optional or Add-on Modules: Many systems require additional modules like enhanced pre-treatment, advanced post-treatment (e.g., UV sterilization, EDI), or sophisticated monitoring systems. Each adds to the initial investment.

- Installation Costs: Site preparation, plumbing, electrical work, and commissioning by skilled technicians are significant cost considerations.

- Customization Premiums: For unique requirements or highly challenging water sources, tailored solutions incur additional engineering and manufacturing costs.

3.2 Operational and Maintenance Costs

Beyond the initial purchase, understanding ongoing costs is crucial for accurate financial planning:

- Energy Consumption: Pumping water, especially in RO systems that require high pressure, consumes significant electricity. Heating or cooling for specific processes also adds to energy bills.

- Consumables: This category includes regular replacements such as filter cartridges, membranes (which have a finite lifespan), and chemicals used for cleaning, pH adjustment, or disinfection. Ocpuritech, for example, stocks a wide range of spare parts like filter cartridges to support customer needs.

- Labor: Costs associated with monitoring, routine maintenance, and occasional troubleshooting by trained personnel.

- Spare Parts: Beyond standard consumables, parts like UV lamps, FRP tanks, carbon, and flow meters may need replacement over time due to wear and tear.

3.3 Highlighting Value and ROI

A strategic investment in the best water treatment machinery offers substantial returns:

- Reduced Water Consumption: Efficient systems, especially those with high recovery rates, significantly reduce the overall water footprint and associated costs.

- Compliance with Regulations: Meeting stringent environmental and health regulations avoids costly fines and reputational damage.

- Improved Product Quality and Consistency: For industries like food & beverage or pharmaceuticals, consistent water quality directly translates to consistent product quality, reducing defects and waste.

- Longevity of Equipment: Proper treatment protects downstream equipment from scaling and corrosion, extending its lifespan and reducing replacement costs.

- Reduced Downtime: Reliable water treatment means fewer operational interruptions, ensuring continuous production.

- Savings on Chemical Costs: Advanced physical treatment methods can reduce the reliance on chemical additives.

From my observations through numerous industrial projects, companies that prioritize quality water treatment often see their investments recouped within a few years through these tangible savings and improved operational efficiencies. Ocpuritech, with its two standardized factories, emphasizes cost-effective solutions without compromising on quality, aiming to enhance this ROI for its clients.

Performance Specifications & Quality Assurance

When evaluating the best water treatment machinery, scrutinizing performance specifications and understanding quality assurance measures are paramount. These details determine a system’s effectiveness, longevity, and overall trustworthiness.

4.1 Key Performance Indicators (KPIs)

KPIs offer a quantitative measure of a system’s efficiency and capability:

- Flow Rate: Measured in Gallons Per Day (GPD) or cubic meters per hour (m³/h), this indicates the volume of treated water produced.

- Recovery Rate: The percentage of influent water converted into treated water. Higher recovery rates mean less wastewater. In my experience, striving for optimal recovery is critical for sustainability and cost reduction.

- Pollutant Rejection Rates: Specifically for RO and NF, this specifies the percentage of dissolved solids, salts, or other contaminants removed.

- Turbidity, TDS, Conductivity Reduction: Measures the clarity and purity of the treated water compared to the raw water.

- Energy Efficiency: How much energy is consumed per unit of treated water, a crucial factor for operational costs.

- System Lifespan and MTBF (Mean Time Between Failures): Indicators of expected operational longevity and reliability.

4.2 Material Selection and Construction Standards

Durable and appropriate materials are foundational to a system’s performance and safety:

- Stainless Steel (304/316): Widely used for piping, frames, and pressure vessels due to its excellent corrosion resistance and hygiene properties. Type 316 offers superior resistance in highly corrosive environments.

- FRP (Fiberglass Reinforced Plastic): Common for filter tanks and pressure vessels, offering good corrosion resistance and strength at a lower cost than stainless steel.

- PVC: Often used for low-pressure piping and fittings, known for its chemical resistance and affordability.

- Food-Grade Materials: Absolutely essential for equipment used in food, beverage, and pharmaceutical industries to prevent contamination and ensure product safety.

4.3 Quality Control and Certifications

Reputable manufacturers adhere to stringent quality control processes and obtain relevant certifications, providing assurance of product quality and compliance:

- ISO Standards (ISO 9001, ISO 14001): Demonstrate a manufacturer’s commitment to quality management systems and environmental management, respectively.

- NSF, CE, RoHS Compliance: Depending on the region and application, certifications like NSF (for drinking water components), CE (for European market safety), and RoHS (for restriction of hazardous substances) may be required.

- Internal QC Processes: Beyond external certifications, a manufacturer’s internal quality assurance processes during manufacturing are critical. This includes rigorous testing of components and complete systems before shipment. Ocpuritech’s factory capabilities include comprehensive testing protocols designed to ensure every unit meets the highest standards.

Market & Application Scenario Analysis

The global demand for clean water varies significantly by region and industry. A thorough market and application scenario analysis is vital for selecting the best water treatment machinery that directly addresses specific challenges and needs.

5.1 Regional Water Quality Characteristics

Water quality differs dramatically across geographies, influencing the choice of treatment technology. For example, in many parts of Southeast Asia, Africa, and South America, as observed in my work, one might encounter very specific challenges:

- Hardness: High mineral content, requiring softening.

- Salinity: Brackish groundwater or coastal proximity necessitates RO systems. The emergence of new membrane technology that equips membranes used in reverse-osmosis desalination with electrical conductivity is improving their ability to separate salts and other contaminants from hard-to-treat waters, enhancing membrane efficiency and sustainability, as supported by the National Alliance for Water Innovation (NAWI).

- Specific Contaminants: Elevated levels of iron, manganese, arsenic, or microbial contamination, which demand specialized filtration and disinfection steps. For instance, advancements in membrane-based technologies are crucial for metal recovery and environmental sustainability in industrial wastewater treatment.

These regional variations directly impact equipment selection, pre-treatment needs, and overall system design.

5.2 Industry-Specific Demand Analysis

Different industries have distinct water quality and quantity requirements:

- Pure Water Projects: Industries like urea production, hydrogen production, medical facilities, pharmaceuticals, photovoltaics, and cosmetics demand ultra-pure water with extremely low conductivity and impurity levels.

- Drinking Water: This includes municipal supplies, bottled water production lines (where Ocpuritech has significant experience), and domestic use, requiring adherence to strict health and safety standards.

- Seawater Desalination: Coastal communities and islands rely heavily on desalination to secure a stable freshwater supply.

- Other Niche Markets: This could include specialized systems for car washes, textile dyeing, or laboratory research, each having tailored water specifications.

5.3 Solution Adaptability and Customization

The best water treatment machinery is not a one-size-fits-all solution. Adaptability and customization are key:

- Systems must be tailored to meet unique customer requirements, ranging from small-scale residential units to vast industrial plants.

- This involves configuring pre-treatment stages, selecting appropriate membrane types, and designing post-treatment processes to achieve the desired output water quality.

- Manufacturers like Ocpuritech often work closely with clients to perform detailed water analysis and design bespoke solutions that optimize efficiency and reduce operational costs. My involvement in projects requiring highly specific water quality for microelectronics has highlighted the critical role of custom engineering in achieving precise outcomes. Innovations that enhance efficiency and environmental compatibility contribute to more sustainable industrial water management.

Case Studies: Real-World Impact

The true measure of the best water treatment machinery lies in its real-world impact. These case studies illustrate how effective water treatment addresses challenges and delivers tangible benefits.

6.1 Success Story 1: Industrial Application

A leading pharmaceutical factory struggled with inconsistent water quality, affecting batch integrity and operational efficiency. The challenge was to provide an uninterrupted supply of ultrapure water, free from ionic impurities and microbial contamination, for critical drug manufacturing processes.

The solution involved installing an integrated system featuring advanced pretreatment followed by a robust Reverse Osmosis unit and a final EDI stage. The system was designed with redundancy to ensure continuous operation. This comprehensive membrane technique for wastewater treatment drastically improved water purity, leading to:

- Improved product quality and consistency, with zero batch rejections due to water quality issues.

- Full compliance with stringent pharmaceutical regulatory standards.

- Reduced downtime for system maintenance due to optimized automated controls.

6.2 Success Story 2: Drinking Water Project

In an arid region of Africa, a community faced severe lack of access to safe drinking water, relying on brackish groundwater sources that were unsuitable for consumption. The challenge was to provide a sustainable and cost-effective solution for potable water production.

A compact, skid-mounted brackish water RO system was implemented. This system included robust pre-filtration to handle high levels of suspended solids, followed by a high-efficiency RO membrane able to significantly reduce salinity. The results were transformative:

- Direct access to clean, safe drinking water for thousands of residents.

- A notable improvement in public health outcomes due to reduced waterborne diseases.

- Empowerment of the local community through reliable access to a vital resource.

6.3 Success Story 3: Commercial Application

A beverage bottling plant aimed to expand its production capacity and ensure premium product quality, identifying inconsistencies in their water supply as a bottleneck. The core challenge was achieving consistent, high-purity water for bottling while integrating seamlessly with their existing filling line.

A complete RO purification system was installed, specifically designed for beverage applications, featuring advanced pre-treatment, a high-capacity RO unit, and UV sterilization for final disinfection. This system was integrated directly into their bottling line, including conveyors for rinsing, filling, and capping. The outcome was highly successful:

- Increased production efficiency and throughput, meeting expanded market demand.

- Enhanced beverage taste and extended shelf life due to superior water quality.

- Significant cost savings from reduced product rejections and optimized water usage.

Customization & Service Support: Partnership for Purity

In the realm of water treatment, effective solutions are rarely off-the-shelf. The best water treatment machinery is often a customized system backed by strong service support, creating a true partnership for purity.

7.1 Tailored Solutions

Customization is key to addressing the unique characteristics of each water source and the specific demands of every application:

- Pre-treatment and Post-treatment Options: These are meticulously selected based on comprehensive raw water analysis and the desired output water quality. My experience has shown that overlooking proper pre-treatment can severely compromise the lifespan and efficiency of the main treatment unit.

- Scalability for Future Expansion: Designing systems with future growth in mind allows for seamless capacity upgrades, protecting initial investments.

7.2 Installation & Commissioning

Professional installation and expert commissioning are critical for optimal system performance:

- Professional Guidance: Manufacturers should provide detailed installation manuals and, often, remote or on-site supervision.

- Onsite Support: For complex industrial systems, direct physical presence by trained engineers during installation and startup ensures that all components are correctly integrated and calibrated for peak efficiency.

7.3 Maintenance & After-Sales Service

Ongoing support is what truly distinguishes reliable partners like Ocpuritech:

- Regular Check-ups: Scheduled inspections and preventative maintenance help identify potential issues before they escalate into costly breakdowns.

- Spare Parts Supply: Readily available spare parts, including filter cartridges, membranes, and UV lamps (which Ocpuritech stocks), minimize downtime and ensure continuous operation.

- Technical Support: Access to expert technical assistance for troubleshooting and operational guidance is invaluable.

- Warranty Information: Clear warranty terms provide peace of mind regarding the quality and durability of the equipment.

My work has consistently shown that robust after-sales support, characterized by “sincere service and professional technology experience,” is as crucial as the hardware itself for ensuring long-term satisfaction and system efficacy.

Manufacturer’s Expertise & Collaborative Advantage

Choosing the right manufacturing partner is as critical as selecting the best water treatment machinery itself. Their expertise, infrastructure, and commitment to collaboration significantly impact the success of your water treatment initiatives.

8.1 Company Profile & Technical Prowess

Ocpuritech, established in 2011, brings 14 years of dedicated experience to the water treatment industry. Our technical prowess is underscored by:

- Two Standardized Factories: Locations in Guangzhou and Jiangmen, totaling over 10,000 square meters, enable efficient and high-volume production of quality and cost-effective products. This scale ensures consistent quality control and timely delivery.

- Innovation and R&D: Continuous investment in research and development to integrate the latest advancements in membrane technology and automation.

8.2 Certifications & Global Reach

Our commitment to quality is reflected in various standards and Our products are trusted and praised by customers from all over the world. Our global reach is particularly strong in diverse markets such as Southeast Asia, Africa, and South America, where we have successfully deployed solutions tailored to regional water quality challenges. My involvement in projects across these continents confirms that localized expertise, coupled with robust technology, is essential for truly effective water solutions.

8.3 Collaborative Opportunities

Ocpuritech actively seeks to build strong partnerships across the water treatment ecosystem:

- Water Treatment Wholesalers, Agents, and Accessory Sellers: Partnering with us provides access to a comprehensive product portfolio and expert support, enhancing their market presence.

- Pure Water Project Customers: We collaborate closely with clients on industrial pure water and ultrapure water projects, providing end-to-end solutions from design to commissioning.

- Global Cross-Border E-commerce Buyers: Our streamlined processes and logistics support enable efficient procurement and delivery of water treatment solutions worldwide.

The value proposition of partnering with a seasoned manufacturer like Ocpuritech lies in gaining a reliable supplier, a knowledgeable consultant, and a technical partner dedicated to your success.

Conclusion & Investment Advice

Investing in the best water treatment machinery is not merely a purchase; it’s a strategic decision that underpins health, sustainability, and economic prosperity. The journey through advanced membrane technologies, cost considerations, quality assurance, and diverse applications reveals the immense importance of thoughtful selection and reliable partnership.

Modern water treatment technology offers significant ROI by reducing operational costs, improving product quality, ensuring regulatory compliance, and most importantly, providing access to clean water. Enterprises and communities alike stand to gain substantially from these innovations.

At Ocpuritech, our commitment stands firm: to provide quality, affordability, and unwavering customer success. “We are dedicated to helping our customers develop their businesses on drinking and selling bottle water, or for other purposes.” This dedication is rooted in our comprehensive experience and state-of-the-art manufacturing capabilities.

We encourage all prospective buyers—whether a wholesaler, project customer, or e-commerce client—to thoroughly assess your specific needs, consult with experts for tailored solutions, and consider Ocpuritech as your trusted partner. As Mrs. Carrie Chan, our founder, envisions, we aspire to make clean and pure water accessible to everyone, a vision that drives our responsibility towards both environmental protection and global well-being.

FAQ Section

Q1: What factors should I consider when choosing the best water treatment machinery for industrial use?

When choosing industrial water treatment machinery, consider raw water quality, desired output water specifications, required flow rate, budget (both capital and operational costs), maintenance requirements, energy consumption, system scalability, and the manufacturer’s reputation for support and quality.

Q2: How does a Reverse Osmosis (RO) system work, and is it always the best water treatment machinery option?

An RO system works by forcing water under high pressure through a semi-permeable membrane, which blocks dissolved solids, salts, and impurities. While highly effective for producing high-purity water and desalination, it’s not always the “best” option. Other technologies like UF, NF, or EDI might be more suitable depending on the specific contaminants, desired water quality, and cost-efficiency for a given application.

Q3: What are the typical maintenance requirements and costs for best water treatment machinery?

Typical maintenance includes regular cleaning of filters and membranes, replacement of consumables (filter cartridges, UV lamps, chemicals), calibration of sensors, and periodic system checks. Costs vary based on system size, raw water quality, and operational hours but primarily involve energy, consumables, and labor for servicing.

Q4: Can the best water treatment machinery be customized for specific water sources like brackish or seawater?

Yes, absolutely. The best water treatment machinery, especially RO systems, can and often must be customized for specific water sources. This involves selecting appropriate membrane types, designing specialized pre-treatment stages to handle unique contaminants (e.g., high turbidity or biological fouling in seawater), and optimizing system pressure and flow rates.

Q5: What are the key differences between UF, NF, and RO in the context of the best water treatment machinery?

The key difference lies in their pore sizes and the types of contaminants they remove. Ultrafiltration (UF) removes suspended solids, bacteria, and viruses. Nanofiltration (NF) removes divalent ions and larger organic molecules. Reverse Osmosis (RO) has the smallest pore size, removing virtually all dissolved solids and salts, producing the purest water among the three membrane technologies.

Q6: How do I determine the right capacity for my water treatment machinery investment?

Determining the right capacity involves calculating your peak and average daily water demand. Consider current needs, future expansion plans, and any regulatory requirements for flow rate and storage. A reputable manufacturer can help conduct a water audit and recommend an appropriately sized system.

Q7: What kind of pre-treatment is necessary before installing best water treatment machinery?

Pre-treatment is crucial and varies with raw water quality. Common stages include multimedia filtration (for suspended solids), activated carbon filtration (for chlorine and organic matter), and water softening (for hardness). Without proper pre-treatment, membrane life can be significantly reduced due to fouling or scaling.

Q8: What after-sales support can I expect when investing in industrial water treatment machinery?

Expect comprehensive after-sales support including installation guidance, commissioning services, technical troubleshooting through phone or online channels, spare parts availability, and potentially on-site maintenance contracts. Choose manufacturers known for reliable and responsive customer service.

Q9: How do I ensure the longevity and efficiency of my best water treatment machinery?

Ensure longevity and efficiency through regular preventative maintenance, using genuine spare parts, monitoring system performance closely, and following the manufacturer’s operational guidelines strictly. Proper pre-treatment and periodic cleaning of membranes are also vital.

Q10: What are the environmental benefits of investing in efficient water treatment machinery?

Environmental benefits include reduced freshwater consumption through recycling and reuse, minimized discharge of pollutants into natural water bodies, lower energy consumption (for high-efficiency systems), and decreased chemical usage due to advanced physical separation technologies. This contributes to water conservation and environmental protection.