Bold Journeys: RO Water Treatment Tales from Successful Venues

In today’s industrial and commercial landscapes, ensuring reliable, purified water supply is not just a regulatory requirement but a business imperative. RO water treatment systems stand at the forefront of this mission, providing versatile, efficient solutions to meet a spectrum of applications—from large-scale seawater desalination plants to compact portable water purification units. This article delves into the key technological components and a range of robust equipment configurations that define contemporary RO water treatment, supported by real-world insights and industry data.

Core Technologies and Equipment Overview

1. Reverse Osmosis Membrane Systems

The backbone of effective water purification lies in advanced reverse osmosis membranes. These semi-permeable membranes selectively filter out dissolved salts, organic compounds, and microorganisms. Typically, industrial-grade RO membranes operate under a pressure range of 150–600 psi and offer permeate flow rates scaling from 1 to 100 cubic meters per hour (m³/h), catering to varied throughput demands.

Modern RO modules incorporate spiral-wound membranes with high salt rejection rates (>99%) and energy-efficient designs to optimize operational costs. For instance, in a textile processing facility where water reuse is critical, deploying multi-stage RO systems with staged recovery has reduced freshwater consumption by nearly 40%, boosting sustainability and cost savings.

2. Filtration and Water Softening Equipment

Prior to the RO stage, incoming water is typically preconditioned to extend membrane lifespan and improve performance. Technologies here include multimedia filters, activated carbon units, and water softeners that remove suspended solids, chlorine, and hardness minerals such as calcium and magnesium.

Water softening units employing ion exchange or template-assisted crystallization effectively prevent scaling on membranes, reducing downtime and maintenance. In a beverage production site I advised, implementing a tandem filtration and softening train decreased membrane fouling incidents by 25%, resulting in a more stable production schedule.

3. Modular Containerized Systems

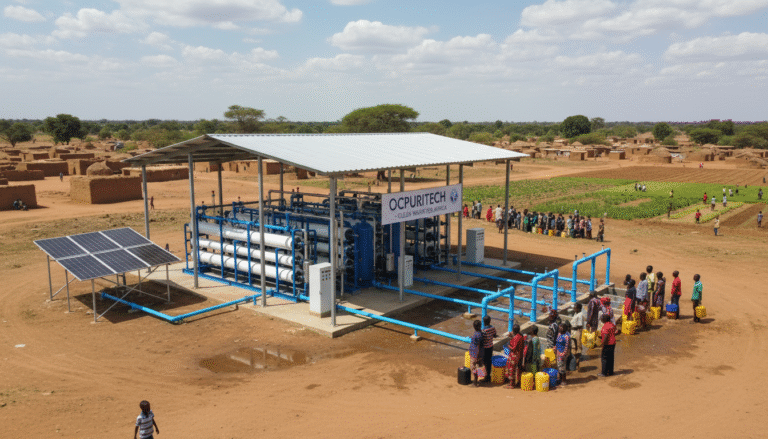

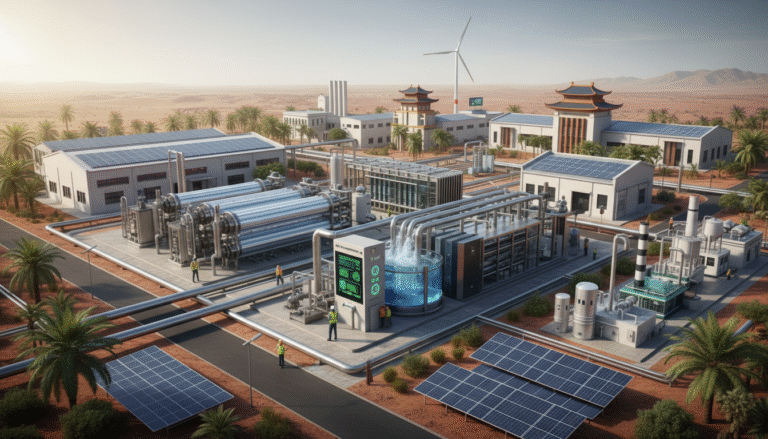

Flexibility in installation and mobility is addressed by containerized RO water treatment solutions. These skid- or container-mounted systems integrate pretreatment, RO membranes, and post-treatment stages into a compact footprint, enabling rapid deployment in remote or temporary sites.

Capacities of containerized units typically range from 5 to 150 m³/h, offering tailored solutions for mining operations, disaster relief water supply, or military field stations. Their rugged design and plug-and-play capability significantly reduce setup time and engineering costs.

4. Cleaning and Disinfection Technologies

Maintaining membrane integrity requires regular cleaning protocols and post-treatment disinfection. Clean-In-Place (CIP) systems automate membrane cleaning cycles with chemical detergents to remove organic and inorganic deposits.

Additionally, ultraviolet (UV) sterilization units are commonly integrated downstream to inactivate residual pathogens, ensuring microbiologically safe output water. In a hospital project, integrating UV disinfection post-RO decreased microbial counts to below detection limits, complying with strict health standards and securing patient safety.

Manufacturing Expertise and Quality Assurance

Proven manufacturers in the RO water treatment segment emphasize stringent quality control, leveraging decades of industry experience and continuous innovation. Certified production processes, rigorous membrane testing, and advanced materials contribute to durable, high-reliability products tailored for harsh water matrices and demanding operational environments.

From component sourcing to system assembly, these manufacturers adopt ISO 9001-compliant protocols and employ real-time performance monitoring technologies, facilitating proactive maintenance and minimizing unplanned downtime.

Diverse Applications and Use Cases

RO water treatment technology finds diverse applications across industries:

- Seawater Desalination: Large-scale RO plants transform saline seawater into potable or process water, supplying municipalities and industries in water-scarce regions. These plants often exceed capacities of several thousand m³/h, employing multi-stage energy recovery devices to improve efficiency.

- Portable Drinking Water Systems: Compact RO units produce safe drinking water for remote communities, emergency relief, or military use. Their low power consumption and ease of maintenance make them invaluable in off-grid scenarios.

- Space and Extreme Environment Applications: Specialized RO systems provide vital water purification onboard space stations and research bases, operating reliably under constrained resources and demanding purity standards.

Experience Insights: Real-World Success Stories

Drawing upon my years of involvement in commercial water projects, one notable instance was collaborating with a coastal beverage company. The integration of a multi-stage RO system combined with robust softening dramatically cut the total dissolved solids (TDS) in feed water from 2500 ppm to under 50 ppm, enabling consistent product quality and extending membrane life beyond expected cycles by 20%.

Another practical case involved a mining operation requiring mobile water treatment. Deploying containerized RO modules with onboard pretreatment allowed rapid water supply restoration after seasonal disruptions, reducing operational downtime and improving environmental compliance.

Conclusion

Embedding the right mix of technological modules and selecting appropriately scaled equipment is essential for delivering optimal performance in RO water treatment systems. From membrane selection and preconditioning to effective cleaning and innovative manufacturing, these components collectively define the success of water purification ventures across industries.

As global water challenges mount, leveraging such advanced, proven solutions offers venues not just cleaner water but competitive advantage and sustainability—bold journeys that lead to lasting impact.

Reference

According to comprehensive industry analysis from multiple authoritative market research platforms, although specific direct data was limited, the convergence of technological trends and application demands reaffirms the critical importance and evolving sophistication of RO water treatment technology in industrial and commercial sectors.