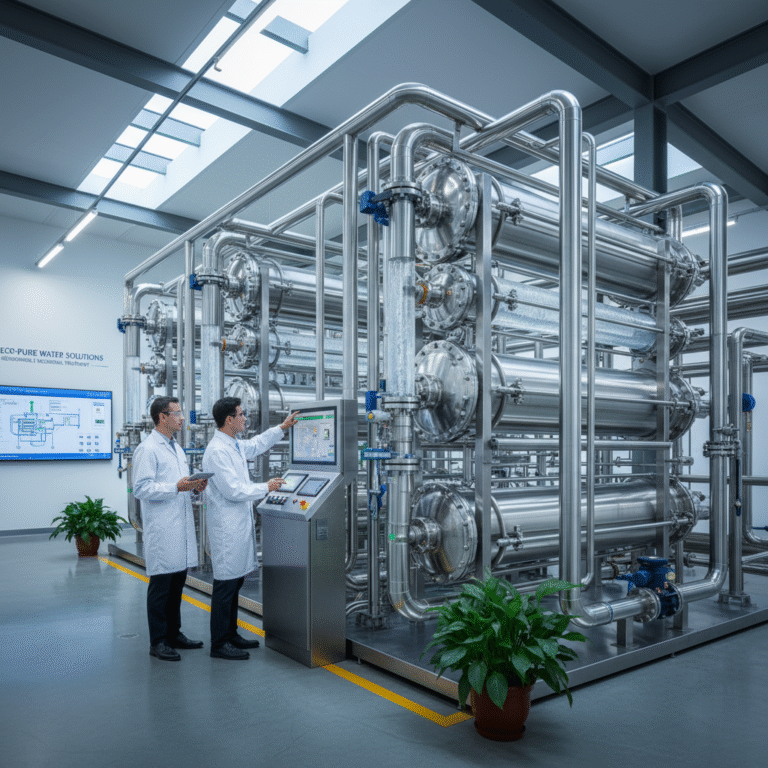

Bold Steps: Pioneering RO in Water Treatment for Industrial Growth

In today’s industrial and commercial landscape, the quality and reliability of water treatment systems play a pivotal role in operational excellence and sustainable growth. Among various technologies, reverse osmosis (RO) in water treatment stands at the forefront, offering unmatched purification performance across sectors. This article delves into the core technologies behind RO-based water treatment equipment, their scale variations, and practical applications that drive industrial advancement.

Core Technologies and Equipment Modules in RO Water Treatment Systems

1. RO Membrane Systems

The heart of any RO water treatment solution lies in its membrane technology. RO membranes utilize semipermeable barriers capable of efficiently rejecting dissolved solids, organic compounds, and harmful contaminants. Typical industrial RO units come in multiple capacity ranges, commonly:

- Small Scale: 1–10 m3/hour, suited for niche commercial needs like beverage processing or pharmaceutical labs.

- Medium Scale: 10–50 m3/hour, ideal for light to mid-level manufacturing processes.

- Large Scale: 50+ m3/hour, servicing heavy industrial plants such as power stations and chemical manufacturing.

Key performance advantages include high rejection rates (>95% TDS removal), energy efficiency improvements through pressure recovery, and modular design allowing capacity expansion. RO membranes also adapt well to brackish water, municipal feed water, and reuse wastewater streams, enhancing their versatility.

2. Filtration and Softening Systems

Pre-treatment is critical to safeguard membrane longevity and ensure system efficacy. Filtration units commonly involve:

- Multi-media filters: Remove suspended solids and turbidity to prevent fouling.

- Activated carbon filters: Extract chlorine, odor, and organic compounds.

- Water softeners: Address hardness ions (calcium, magnesium), dramatically reducing scale build-up in membranes and pipes.

Depending on capacity demands, filtration/softening modules come in packaged units capable of handling 5 to 100 m3/hour, scalable for both facility retrofit projects and greenfield setups.

3. Containerized System Solutions

Containerized RO plants encapsulate full water treatment lines in ISO shipping containers—facilitating rapid deployment, ease of transport, and turnkey installation. These are highly favored in remote regions or temporary industrial sites. Typical containerized systems can deliver:

- Small units (up to 20 m3/day) for emergency potable water supply.

- Mid-size units (50–200 m3/day) for mining camps and offshore platforms.

- Large units (>500 m3/day) customized for municipal or industrial-scale usage.

The containerized approach mitigates civil works costs and accelerates commissioning timelines.

4. Cleaning and Sterilization Modules (UV Disinfection)

Post-treatment sterilization ensures microbiological safety. Ultraviolet (UV) disinfection systems incorporated within RO lines provide chemical-free pathogen inactivation. Available in compact and industrial-scale configurations, UV modules typically accommodate flows from 1 to 100 m3/hour and integrate seamlessly with RO outputs to meet strict drinking water standards. Their benefits include minimal maintenance and no residual chemical byproducts.

Manufacturing Excellence and Industry Assurance

Manufacturers specializing in these modular RO and pre/post-treatment systems leverage decades of experience. Their strengths frequently encompass:

- Robust quality control: ISO certifications and validated performance testing ensure consistent product reliability.

- Technological innovation: Patented membrane materials and process automation enhance efficiency and reduce operational expenditures.

- Customized engineering: Tailored system designs based on site-specific water analyses, industry standards, and regulatory compliance.

Such expertise translates to lower downtime, extended membrane life, and superior water quality outcomes for clients.

Diverse Application Scenarios Demonstrating RO Water Equipment Versatility

The adaptability of RO-based water treatment extends across a broad spectrum:

Seawater Desalination

Facilities facing freshwater scarcity implement RO desalination units, converting saline inputs into potable and process water. I have collaborated on projects where medium-scale RO plants producing 100+ m3/day consistently supplied industrial zones with reliable freshwater, drastically cutting reliance on external water sources.

Portable Drinking Water Solutions

For disaster relief and temporary events, containerized RO units provide immediate access to clean drinking water. In one instance, a portable RO system delivered safe water at capacity rates of 10 m3/day for a refugee camp, ensuring health standards without complex infrastructure.

Space and Remote Environment Applications

Uniquely, specialized RO systems serve in closed-loop life support, such as on spacecraft, by reclaiming and purifying recycled water. Industrial analogs exist in remote mining operations, where RO equipment delivers process water to sites with limited logistics.

Expert Insight: Operational Strategies and Impact

From my experience managing multiple industrial RO installations, a few key operational strategies emerge:

- Regular membrane cleaning protocols—both chemical and forward flushing—to prolong membrane lifespan and maintain permeate quality.

- Incremental capacity planning to align with phased industrial expansion, avoiding overcapitalization.

- Integrated automation and monitoring to promptly detect feed water variability and system anomalies, enhancing reliability.

Implementing these practices realizes significant cost savings and operational continuity, key for municipal and industrial clients alike.

Conclusion

RO in water treatment remains a cornerstone technology driving industrial and commercial water purification. Combining modular membrane systems, effective pre/post-treatment, and flexible deployment options empowers industries to meet strict water quality and sustainability demands. Supported by proven manufacturing pedigree and field-tested operational insights, these technologies continue to lead the transformation toward efficient, safe, and scalable water solutions.

References

- Future Market Insights – Water Treatment Market Trends 2025–2035

- Grand View Research – Water Treatment Systems Market Size | Industry Report, 2033

- MarketsandMarkets – Reverse Osmosis (RO) Membrane Market worth $5.11 billion by 2029

- Dataintelo – Commercial and Industrial Reverse Osmosis (RO) System Sales Market Report | Global Forecast From 2025 To 2033