Selecting the ideal reverse osmosis water system for industrial and commercial applications is critical for ensuring reliable, high-quality water purification. In sectors ranging from agriculture to pharmaceuticals, water treatment equipment must meet rigorous standards, balancing efficiency, capacity, and purity. This article explores core technologies and product lines foundational to modern water treatment plants, combining technical insights with practical use cases to guide professionals in making informed decisions.

1. Core Technology Modules in Reverse Osmosis Water Systems

At the heart of many effective water treatment plants lies the Reverse Osmosis (RO) membrane technology. RO systems utilize semi-permeable membranes to remove dissolved solids, organic molecules, salts, and contaminants. Their high purification level surpasses that achieved by ultrafiltration or nanofiltration, providing potable and process water suitable for demanding industrial requirements.

Complementing the RO membranes, pretreatment modules are essential for sustaining system longevity and performance. These typically include sand filters to remove suspended solids, carbon filters for organic compounds and chlorine reduction, and water softeners targeting hardness ions. Ultraviolet (UV) disinfection systems add a critical layer of microbial inactivation, ensuring compliance with health-related standards.

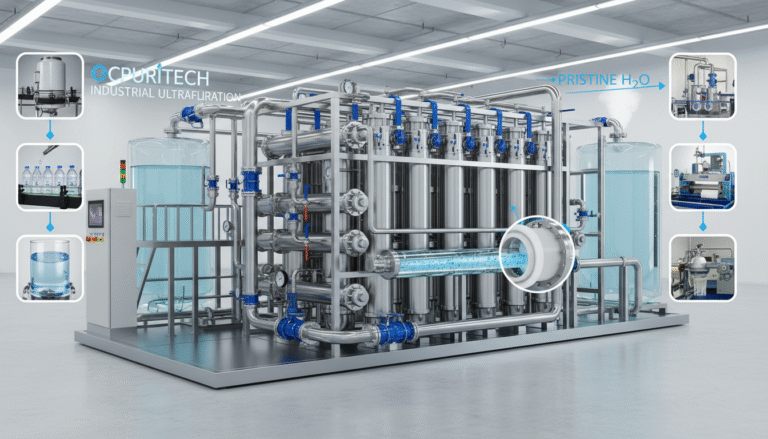

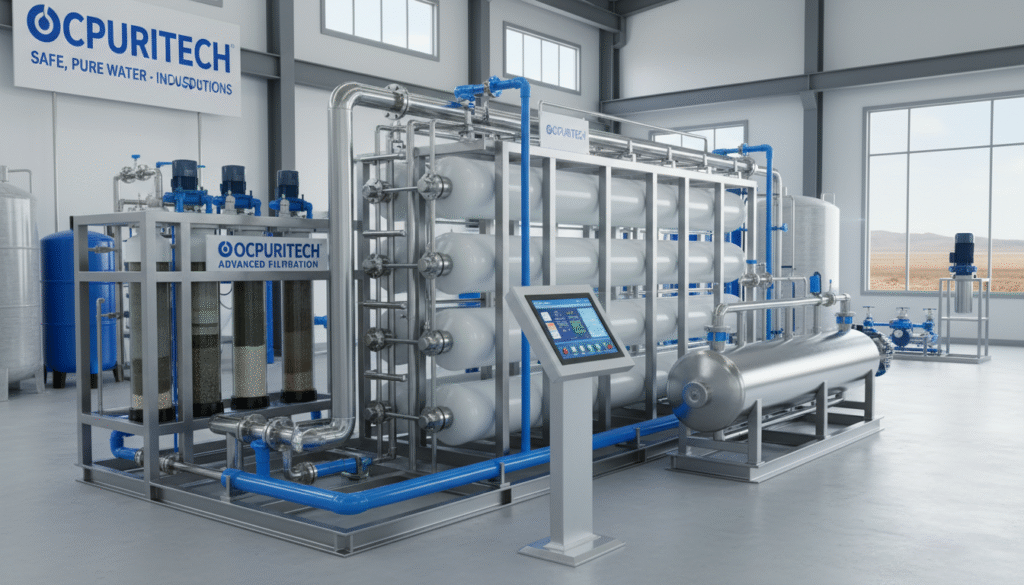

Ocpuritech’s modular design approach facilitates scalable solutions, allowing capacities tailored from low-flow industrial units to large containerized plants exceeding 100,000 liters per hour. This flexibility suits diverse sectors like beverage production, pharmaceutical manufacturing, and municipal water treatment.

2. Equipment Categories and Capacities for Diverse Applications

Industrial and commercial applications benefit from differentiated system categories to match operational demands:

- Small to Medium Industrial RO Systems: Usually providing flows between 500 and 10,000 L/h, these units serve laboratories, hospitals, and mid-sized beverage plants where purity and reliability are paramount.

- Brackish Water RO Systems: Specialized to handle higher salinity feedwaters typical of inland desalination or well water, achieving recovery rates around 50-85% by optimizing membrane selection and preconditioning.

- Seawater Desalination Systems: High-capacity plants operating at advanced recovery efficiencies (up to 85%) designed for coastal municipalities, resorts, or industries requiring large fresh water volumes from seawater feed.

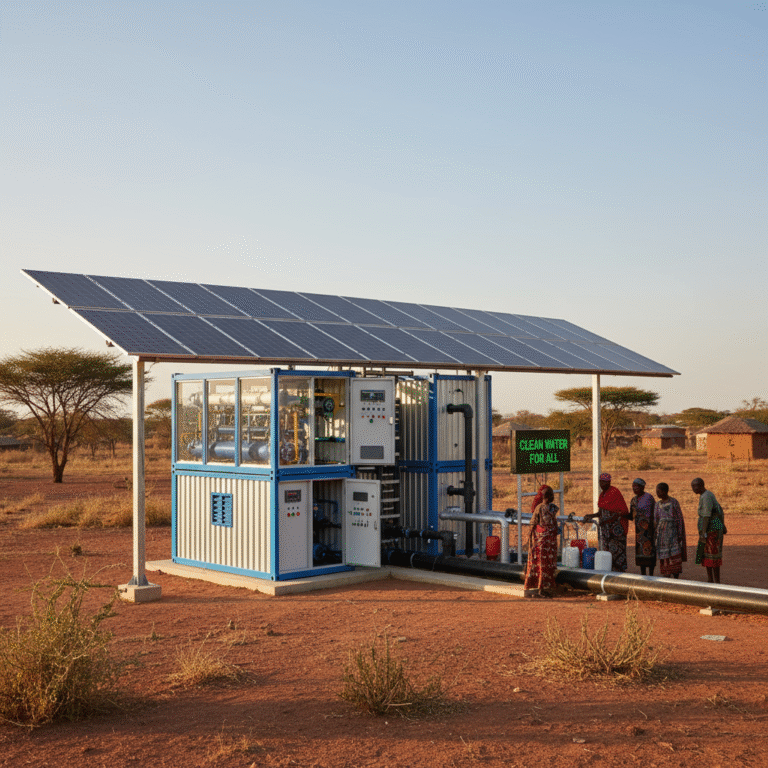

- Containerized and Mobile RO Units: Streamlined for remote or emergency deployments, including space applications or disaster relief, with integrated controls, pretreatment, and UV sterilization.

Such a tiered offering allows facilities to adopt solutions optimized for their unique water quality and production goals while managing operational costs, maintenance, and space constraints.

3. Quality Assurance and Technological Expertise Behind Ocpuritech Systems

Founded in 2011, Ocpuritech leverages over 14 years of industry experience, supported by two expansive factories in Guangzhou and Jiangmen exceeding 10,000 square meters. This robust manufacturing capacity ensures consistent delivery of high-quality water treatment equipment and consumables such as filter cartridges, UV lamps, and flow meters.

Ocpuritech’s commitment to innovation manifests in integrating Remote Control Reverse Osmosis Systems, Ultrafiltration, Nanofiltration, and Electrodeionization (EDI) within versatile product ranges. Their engineering emphasizes ease of maintenance, digital monitoring, and scalable modularity.

The brand’s mission to provide universal clean water access aligns with global environmental responsibility. Customers worldwide rely on Ocpuritech for solutions in sectors like agriculture, cosmetics, pharmaceuticals, and municipal utilities.

4. Real-World Applications and Diverse Use Cases

The adaptability of modern reverse osmosis water treatment systems is evident in their deployment across varied industries:

- Seawater Desalination: Municipalities struggling with freshwater scarcity utilize large-scale RO desalination plants to secure reliable drinking water—especially important in arid regions.

- Portable Drinking Water Treatment: Mobile RO units serve emergency relief operations and military needs, providing potable water in remote or disaster-affected locations.

- Industrial Process Water: Food and beverage manufacturers require stringent removal of contaminants to ensure product quality, accomplished via multi-stage RO and UV integration.

- Space Missions: Advanced RO systems support closed-loop water recycling ensuring life-sustaining water quality in space habitats.

Through these examples, the importance of tailored water treatment solutions becomes clear, with system designs factoring in feedwater characteristics, recovery rate optimization, and maintenance simplicity.

5. Performance Metrics and Optimization Considerations

Efficiency in reverse osmosis systems is often measured by the recovery rate — the percentage of input water converted to purified output. Typical recovery rates for industrial RO units range between 50% to 85%, with advanced brackish water plants achieving up to 90% recovery without scaling issues, as reported by leading research Morui Water and the University of Texas’s Center for Inland Desalination Systems CIDS UT (2015).

In practice, factors influencing recovery include feedwater quality, pretreatment efficacy, membrane selection, and operational controls. Ocpuritech’s integrated digital monitoring and remote control capabilities facilitate optimized performance and predictive maintenance, reducing downtime and operational costs in challenging environments.

Selecting the right balance between membrane flux, crossflow rates, and UV disinfection intensity results in robust systems that maintain compliance with stringent water quality standards, such as those enforced by NSF/ANSI certifications mentioned in industry standards KnowYourH2O (2021).

In summary, advancing industrial and commercial water purification relies heavily on choosing versatile, high-performance reverse osmosis water systems. Manufacturers like Ocpuritech, with their comprehensive technology portfolios, modular designs, and deep industry expertise, empower customers worldwide to achieve clean, safe water tailored to diverse demands. Understanding system components, operational parameters, and application-specific needs is essential for making the best investment in water safety and sustainability.

FAQ: Choosing the Best Reverse Osmosis Water System for Home Safety

Q1: What factors determine the recovery rate of an industrial reverse osmosis system?

The recovery rate depends on feedwater quality, membrane type, system design, and operational conditions. Advanced systems can achieve recovery rates up to 85% or higher while minimizing membrane scaling.

Q2: How does reverse osmosis compare to ultrafiltration and nanofiltration in water treatment?

Reverse osmosis offers the finest filtration, removing dissolved solids and molecules. Ultrafiltration targets suspended solids and microorganisms, while nanofiltration removes specific dissolved ions and organic matter. Choice depends on specific water contamination and purity needs.

Q3: Can RO systems be used for seawater desalination?

Yes, specialized RO desalination systems are designed for seawater, effectively removing salt and impurities to produce potable water with high efficiency.

Q4: What are the benefits of containerized or mobile RO water treatment systems?

They provide flexible, rapid deployment solutions for remote or emergency situations, integrating pretreatment, RO, and UV disinfection in compact, transportable units.

Q5: How important is system modularity in industrial water treatment?

Modularity allows customization to capacity and water quality needs, simplifies maintenance, and reduces downtime, crucial for diverse industries.

Q6: What role does UV disinfection play in RO water systems?

UV systems inactivate bacteria and viruses post-filtration, enhancing microbiological safety without adding chemicals.

Q7: How can digital remote monitoring improve the operation of RO plants?

Remote monitoring enables real-time performance tracking, predictive maintenance, and prompt issue resolution, increasing reliability.

Q8: Are there specific certifications that guarantee RO water system quality?

Yes, NSF/ANSI certifications such as 58 for reverse osmosis assure system efficacy, safety, and component durability.

Q9: What maintenance practices extend the lifespan of RO membranes?

Regular pretreatment, membrane cleaning, and monitoring of operating parameters prevent fouling and scaling, prolonging membrane life.

Q10: How does Ocpuritech ensure its products meet global water treatment demands?

Ocpuritech combines over a decade of experience, advanced manufacturing capabilities, and research-driven innovations to produce reliable, scalable systems trusted worldwide.