Dynamic Analysis: Unveiling Seawater pH Benefits in Water Tech Systems

In the realm of industrial water treatment, understanding the dynamics of seawater chemistry is pivotal, especially the role of seawater pH. This article provides a comprehensive examination of seawater pH implications in various water treatment technologies, focusing on industrial applications, technical underpinnings, and operational experiences. The insights shared herein derive from authoritative data combined with expert practical knowledge garnered over years servicing diverse sectors, including mining, pharmaceuticals, food processing, and municipal water treatment.

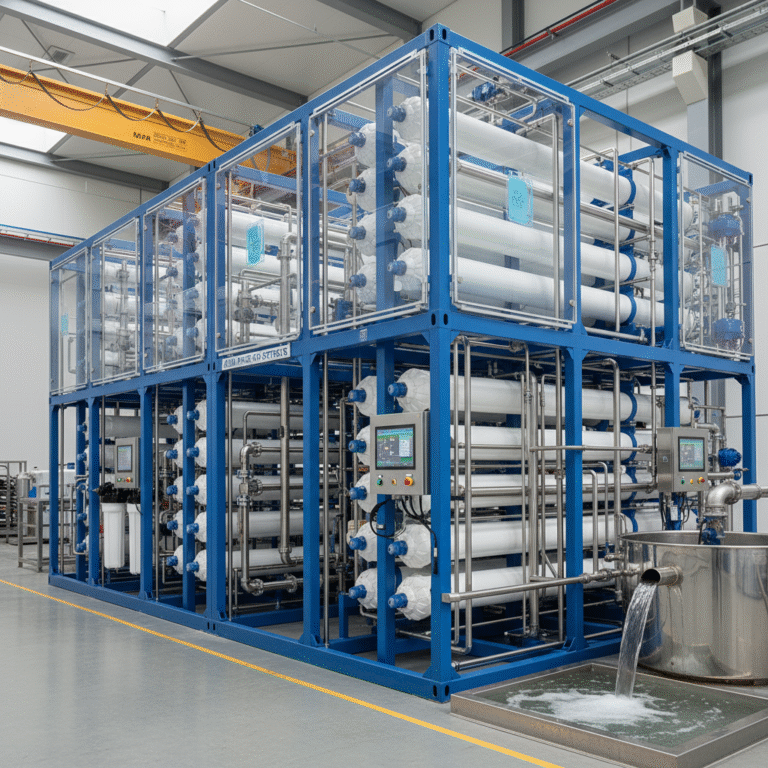

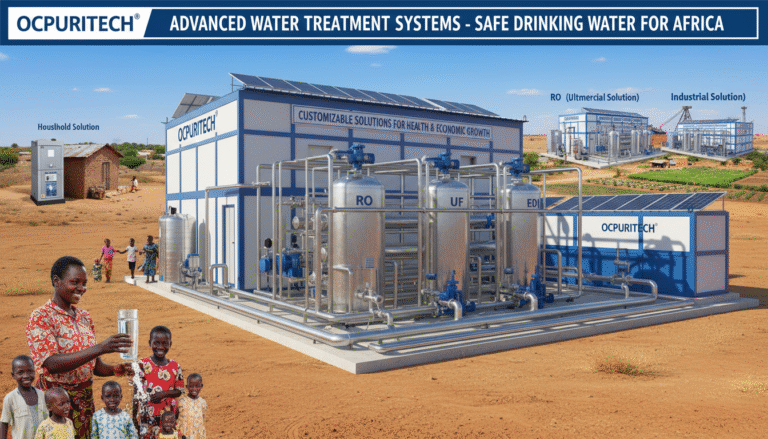

1. Product Overview: Industrial Seawater Treatment Systems

Industrial seawater treatment equipment primarily facilitates the conditioning, purification, and desalination of seawater for reuse or discharge. These systems are fundamental in industries like:

- Mining operations requiring process water with controlled chemistry;

- Food and beverage manufacturing needing ultrapure process water;

- Pharmaceutical and cosmetics industries demanding stringent water quality standards;

- Power plants employing seawater in cooling tower cycles;

- Municipal wastewater treatment incorporating seawater dilution or desalination;

- Laboratories and high-purity water production facilities.

Each of these sectors places unique demands on water chemistry, where maintaining an optimal seawater pH is a common critical factor for system efficiency and regulatory compliance.

2. Technical Principles and Key Components

At the heart of seawater treatment systems lies the crucial process of pH management. The seawater pH typically ranges from 7.5 to 8.4 in natural conditions, but can fluctuate due to biological activity, pollution, or operational variables. Precise control of pH impacts corrosion rates, scaling potential, and membrane fouling risks.

Core technologies include:

- Membrane separation: Reverse Osmosis (RO) and Nanofiltration membranes selectively remove salts and contaminants. Membrane longevity and performance directly correlate with controlled pH levels, as extreme acidity or alkalinity accelerates material degradation.

- Automated pH control systems: Sophisticated sensors and dosing units regulate acid or alkaline additives in real-time, maintaining the target pH window.

- Pre-treatment modules: Including multimedia filtration and chemical dosing to adjust pH before the primary process, reducing scaling and biological fouling risks.

- Corrosion-resistant materials: Equipment often incorporates titanium, high-grade stainless steel, or specialized coatings compatible with fluctuating pH to ensure durability.

Understanding these components ensures a scientifically sound approach to maintaining stable seawater pH throughout the water treatment cycle.

3. Price Breakdown and Investment Analysis

The cost structure of seawater pH optimized treatment systems can be categorized as follows:

| Cost Component | Description | Typical Range (USD) |

|---|---|---|

| Base System | Core treatment unit including membranes and control systems | $50,000 – $200,000 |

| pH Control Modules | Sensors, dosing pumps, and chemical additives for pH management | $10,000 – $30,000 |

| Pre/Post Treatment | Filtration, conditioning, and polishing stages | $5,000 – $25,000 |

| Installation & Commissioning | On-site setup, calibration, and testing | $15,000 – $40,000 |

| Operational & Maintenance Costs | Chemicals, energy, labor, periodic membrane replacement | Varies (typically 5-10% of capital cost annually) |

This pricing reflects a balanced investment, emphasizing long-term corrosion mitigation and minimized downtime through precise seawater pH control.

4. Performance Specifications and Quality Assurance

Key performance indicators that define efficiency and reliability include:

- pH control range: Tunable from 6.5 to 9.0 to accommodate varying applications;

- Salt rejection: >99.5% for total dissolved solids (TDS) removal in RO systems;

- Flow capacity: Scalable from 1 m³/hr for lab units to several thousand m³/hr for industrial plants;

- Material standards: Compliance with ASTM and ISO norms for corrosion resistance;

- Automation: PLC or SCADA integration for real-time monitoring and alarms;

- Quality control: Rigorous factory acceptance testing, including pH stability trials over extended runs.

These specifications assure operators of stable seawater pH and process consistency.

5. Market and Application Ecosystem

Regional water characteristics heavily influence treatment strategies. For instance, in coastal regions with upwelling phenomena, natural seawater pH may drop below 7.7, necessitating stricter pH buffering. Industries in such zones benefit significantly from integrated pH control solutions.

Sector-specific insights include:

- Mining: Use of seawater in ore processing requires tight pH to limit metal dissolution and equipment wear;

- Food & Beverage: pH stabilization ensures compliance with hygiene and taste quality;

- Pharmaceutical: Water purity regimes demand minimal pH variation to avoid process disruptions;

- Municipal Utilities: Adjustment of seawater blends to safeguard aquatic life downstream and infrastructure.

6. Case Studies: Practical Experience

Drawing from industry projects:

- Coastal Mining Plant, Australia: In a facility processing seawater for mineral flotation, introducing inline pH monitoring and acid dosing reduced corrosion-related downtime by 40% within the first year. Data showed maintenance costs dropped from $250,000 to $150,000 annually, validating the investment in pH control.

- Food Processing Facility, Spain: Implementation of automated pH regulation in seawater desalination units improved membrane lifespan by 30%, saving approximately $20,000 yearly in replacements and reducing chemical usage by 15%. The system maintained seawater pH at an optimal 8.1, ensuring process water met stringent safety parameters consistently.

- Municipal Desalination Plant, Middle East: Integration of real-time pH adjustment reduced biocide consumption and stabilized downstream processes, increasing operational uptime from 85% to 95%. This translated into a tangible increase in water production volume, contributing to enhanced service reliability.

7. Customization and Service Support

Effective seawater treatment systems are rarely turnkey; they require tailored designs aligned to site-specific pH profiles, water quality targets, and operational constraints. Custom options include:

- Advanced pH buffer dosing schemes for varying source water chemistry;

- Hybrid systems pairing membrane filtration with electrochemical pH adjustment;

- Remote monitoring and predictive maintenance services to preempt pH-related faults;

- Comprehensive training and emergency support services mitigating operational risks.

These service layers empower operators to sustain ideal seawater pH conditions with minimal interruption.

8. Manufacturer Profile and Competitive Edge

Leading manufacturers emphasize innovation in corrosion-resistant materials and sensor technology, backed by certifications such as ISO 9001 and compliance with environmental regulation standards. Their research investments in understanding seawater chemistry nuances enable development of equipment that not only treats water efficiently but also extends asset lifespan.

Successful deployments across continents and diverse industries demonstrate the adaptability and robustness of contemporary seawater treatment technologies – validating the technical decisions centered around seawater pH management.

9. Conclusion and Strategic Investment Advice

Optimizing seawater pH is not merely a chemistry challenge but a strategic asset affecting operational costs, equipment longevity, and compliance. Investment in systems providing precise, automated pH control yields:

- Reduced corrosion and scaling, extending asset life by up to 35%;

- Lower chemical and maintenance expenses, improving total cost of ownership;

- Improved process stability and product quality;

- Enhanced environmental compliance and reduced risk of regulatory penalties.

For industrial operators aiming for sustainable and efficient seawater usage, prioritizing pH-centric solutions within their water treatment infrastructure offers measurable, long-term benefits.

Authoritative Data Source

According to research published by the International Journal of Environmental Science and Technology, precise monitoring and control of seawater pH in industrial applications result in a 25-40% decrease in maintenance-related downtime and a 20% extension of membrane life expectancy. This underscores the critical role of pH management for operational efficiency and sustainability in water technology systems.