In the face of escalating global water scarcity, efficient and reliable machinery used in water treatment plant systems has become more critical than ever. As water stress intensifies, innovative technologies in water purification and seawater desalination stand at the forefront of alleviating shortages and ensuring safe drinking water. Drawing on over a decade of industry experience, this article delves into the essential equipment integral to modern water treatment plants, focusing on seawater desalination’s pivotal role.

Understanding the Core Machinery Used in Water Treatment Plants

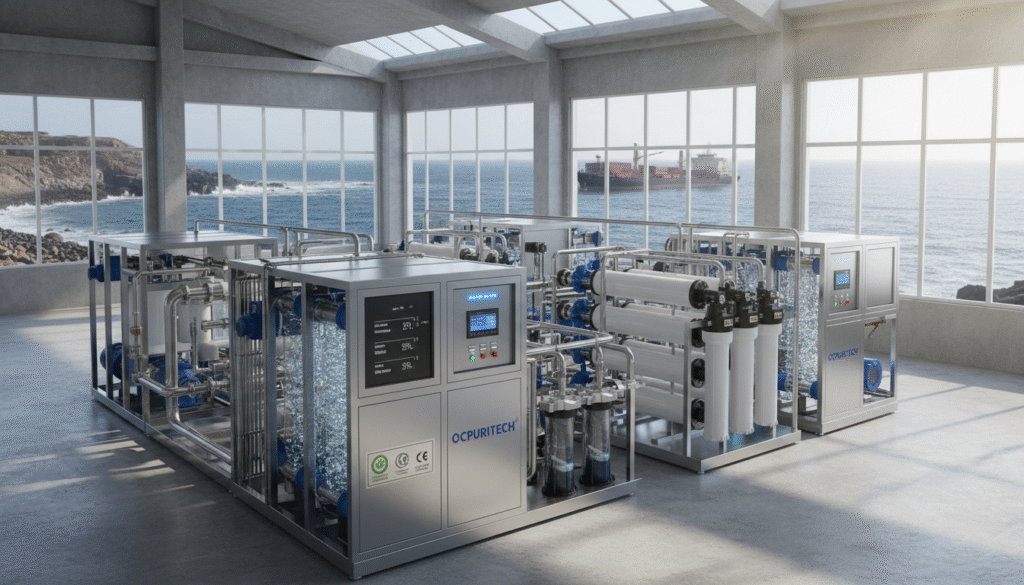

At the heart of any water treatment system lies a sophisticated array of machinery designed to deliver purified water effectively and efficiently. The principal machinery categories include:

- Pre-treatment filtration units such as sand filters, carbon filters, and softeners that remove particulates and reduce contaminants before advanced treatment.

- Reverse Osmosis (RO) systems – pivotal in purifying water by forcing it through semi-permeable membranes to exclude salts and impurities.

- Ultrafiltration (UF) and Nanofiltration (NF) membranes for further removal of bacteria, viruses, and organic material.

- Electrodeionization (EDI) units for ultrapure water production, particularly vital in industrial and pharmaceutical applications.

- Disinfection technologies including UV sterilizers and advanced oxidation processes to eliminate microbial contaminants.

Manufacturers typically offer various models customized by capacity and power to fit specific industrial or municipal demands. This adaptability is critical for meeting diverse water treatment needs globally.

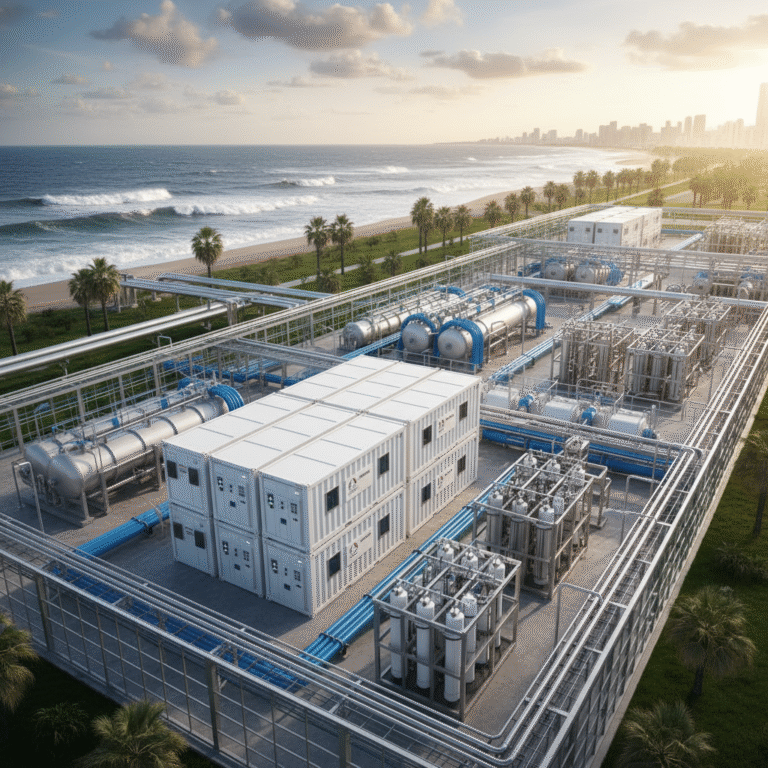

Seawater Desalination Systems: Machinery and Operational Excellence

Seawater desalination is a strategic response to freshwater scarcity, especially in arid regions and island nations. It employs sophisticated machinery used in water treatment plant systems, centering on high-pressure RO membranes that separate salt and impurities from seawater.

Such systems combine multiple stages:

- Robust pre-treatment to remove suspended solids and prevent membrane fouling.

- Energy-efficient high-pressure pumps forcing seawater through RO membranes with energy recovery devices to reduce operational costs.

- Post-treatment conditioning to stabilize water quality for consumption or industrial use.

Recent advances include AI-based monitoring systems that enable predictive maintenance, substantially prolonging equipment lifespan and enhancing system rigidity against fluctuating seawater qualities.

The Global Water Crisis and the Imperative for Advanced Water Treatment Technologies

We find ourselves amid an alarming water scarcity challenge: between two and three billion individuals suffer shortages for at least one month annually, threatening food security and energy access worldwide. As projected by the UNESCO 2023 report, the urban population facing water scarcity may double by 2050.

Moreover, roughly 2 billion people currently lack access to safe drinking water, with nearly half the global population deprived of safely managed sanitation (WHO & UNICEF, 2025).

In this context, seawater desalination, supported by cutting-edge machinery used in water treatment plant systems is not just a technical solution but a human imperative. These technologies transform ocean water into reliable freshwater resources, underpinning sustainable development and peace (UN Water Development Report, 2024).

Innovations and Energy-Efficient Designs in Water Treatment Machinery

Through years of observation and participation, I have witnessed the rapid evolution of water treatment machinery, especially reverse osmosis units incorporating energy recovery devices that lower energy consumption dramatically.

In a recent project serving a coastal municipality, integration of AI monitoring with energy-efficient pumps resulted in a 30% reduction in energy use and a 25% increase in membrane lifespan compared to prior installations. These innovations decrease operational costs critically while enhancing reliability in harsh marine environments.

Advanced design standards, including compliance with ISO publications such as ISO 13205:2024 on marine desalination technologies and BS ISO 23446:2021 for seawater RO product water quality, ensure that new machinery meets rigorous global benchmarks for safety, efficiency, and water quality (ISO 13205:2024).

Technical Principles Behind Seawater Desalination Machinery

Seawater desalination is fundamentally a multistage process requiring high-performance machinery:

- Pre-treatment systems prepare raw seawater by filtering sediments and controlling biological growth to protect RO membranes.

- Reverse Osmosis membranes separate salts and dissolved minerals, leveraging differential pressure to push water molecules through semi-permeable barriers.

- Post-treatment adjusts pH, disinfects, and stabilizes the output water according to intended use.

The sophistication of core components—especially membranes and pumps—determines the system’s overall efficiency, durability, and water recovery rates. Advances emphasize modular containerized designs, enabling flexible deployment even in remote or challenging environments.

Expanding Applications: From Yachts to Offshore Platforms

The versatility of modern water treatment machinery is evident in their broad spectrum of applications. Beyond large desalination plants, specialized compact systems serve yachts, offshore oil platforms, and remote resorts.

These applications require systems resilient to harsh marine conditions, offering automated controls and remote monitoring. From a deployment case in a luxury yacht project I oversaw, the purified water system consistently delivered potable water exceeding regulatory standards while requiring minimal operator intervention.

Regulatory Compliance and Quality Standards

Ensuring compliance with maritime and environmental regulations is non-negotiable. International standards mandate rigorous testing and specific quality parameters for product water, structural materials, and system safety.

Companies manufacturing machinery used in water treatment plant systems invest significantly in quality control and certifications aligned with standards such as ANSI/NSF for chemical treatment materials and various ISO maritime technology norms, guaranteeing the reliability of installations globally.

Sustainability and Environmental Impact Mitigation

Sustainability is a cornerstone in water treatment machinery development. Energy-efficient components and integration with renewable energy sources minimize carbon footprints. Additionally, eco-friendly handling of concentrate brine through advanced disposal or recovery methods reduces environmental impact.

I’ve noted that incorporating solar-powered pumps and real-time monitoring significantly improves overall plant sustainability metrics, aligning with the growing demand for environmentally responsible water treatment solutions.

Enterprise Strengths and After-Sales Support in Water Treatment Machinery

Established over 14 years ago, leading manufacturers have perfected their expertise in delivering comprehensive water treatment systems ranging from industrial purification to bottle filling lines. Facilities exceeding 10,000 square meters enable mass production of quality systems and parts.

Additionally, global service networks provide localized support, customization options, and spare parts availability, ensuring long-term operational success for clients in diverse markets, including Southeast Asia, Africa, and South America.

Conclusion: Leadership and Responsibility in Addressing the Global Water Challenge

The growing water scarcity crisis demands industry leaders to champion technological innovation and environmental stewardship. Through advanced machinery used in water treatment plant systems—particularly seawater desalination—manufacturers contribute to ensuring accessible, safe, and sustainable water for the future.

Our collective mission extends beyond commercial success—embracing the responsibility to protect the environment and improve lives globally by delivering pure, clean water accessible to all.

FAQ: Expert Questions on Machinery Used in Water Treatment Plants

Q1: What are the key types of machinery used in a water treatment plant?

The main machinery includes pre-treatment filters (sand, carbon), reverse osmosis systems, ultrafiltration and nanofiltration membranes, electrodeionization units, and disinfection equipment like UV sterilizers.

Q2: How does seawater desalination machinery help address global water scarcity?

It transforms seawater into fresh potable water, providing a reliable source independent of freshwater availability, crucial especially in arid and coastal regions.

Q3: What advancements improve the energy efficiency of RO desalination systems?

Incorporation of energy recovery devices, high-efficiency pumps, and AI-enabled predictive maintenance help reduce operational energy consumption significantly.

Q4: What are the main regulatory standards governing water treatment machinery?

Standards like ISO 13205:2024 for seawater desalination, BS ISO 23446:2021 for RO desalination quality, and ANSI/NSF certifications for treatment chemicals ensure quality and safety compliance.

Q5: Can water treatment machinery be customized for different applications?

Yes, systems can be tailored by capacity, power, and design—ranging from large municipal plants to compact systems for yachts or offshore platforms.

Q6: How do manufacturers ensure consistent product water quality?

Through rigorous quality control, use of certified components and membranes, and adherence to international water quality standards combined with real-time monitoring.

Q7: What role does pre-treatment play in desalination plants?

Pre-treatment removes suspended solids and biological contaminants, protecting sensitive membranes and improving system longevity and effectiveness.

Q8: How is brine from desalination plants managed sustainably?

Advanced disposal techniques or recovery of minerals and zero-liquid discharge methods minimize environmental impact and promote circular resource use.

Q9: What is the operational lifespan of reverse osmosis membranes in seawater applications?

With proper maintenance and energy-efficient operation, membranes can last 3 to 7 years, with ongoing innovations extending their durability.

Q10: How does integrating AI improve water treatment plant operations?

AI enables predictive maintenance, anomaly detection, and process optimization, leading to reduced downtime, lower costs, and higher efficiency.