Fascinated? What Makes a Reverse Osmosis Water System a Game-Changer?

In today’s industrial world, ensuring access to clean, safe water has never been more crucial. Among numerous technologies, the reverse osmosis water system stands out as a pivotal game-changer in water treatment. This article delves into the complexities of industrial water purification equipment manufacturing and application, providing technical insights and business intelligence for procurement specialists and decision-makers in the B2B sector.

1. The Industrial Water Treatment Landscape: Company and Industry Overview

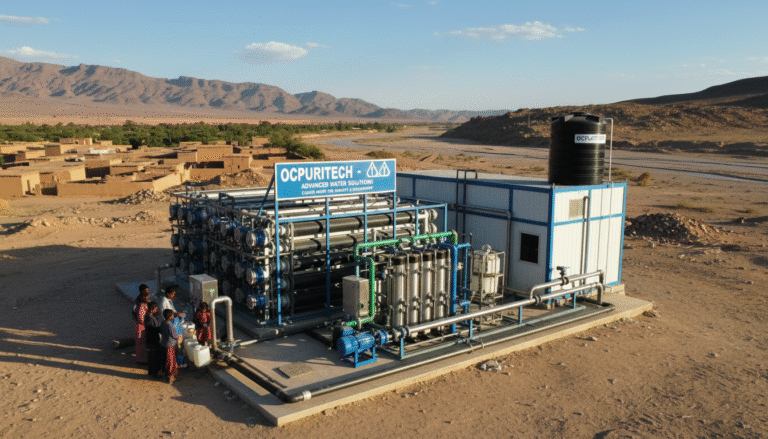

Companies specializing in manufacturing advanced water treatment equipment are at the forefront of tackling global water quality challenges. These organizations emphasize rigorous research and development to innovate high-performance solutions such as reverse osmosis water filtration systems, ultrafiltration, and advanced deionization technologies. Their core philosophy revolves around environmental stewardship and fostering sustainable industrial practices, aligning with increasing regulatory pressures worldwide.

Industrial water treatment is not just an operational necessity but a critical environmental responsibility. The ever-growing demand for clean water sets the stage for water treatment companies to develop proprietary systems that integrate seamlessly into industrial processes while significantly reducing waste and contamination. Such efforts contribute not only to compliance but also to corporate sustainability goals.

2. Product Portfolio: Comprehensive Solutions for Industrial Water Treatment

2.1 Reverse Osmosis Systems

The hallmark of modern water purification, reverse osmosis water purification systems utilize semi-permeable membranes to remove suspended solids, dissolved salts, bacteria, viruses, and other impurities. Typical systems include multi-stage filters—pre-filters, activated carbon, and post-filters—to optimize water quality and membrane longevity.

Technical specifications often include:

- Membrane flux rates ranging from 75 to over 1000 gallons per day (GPD), tailored to application scale.

- Operating pressure adjustments between 150 and 300 psi.

- Recovery rates optimized above 75% to minimize wastewater.

Industries benefiting from these systems include food & beverage, pharmaceuticals, microelectronics manufacturing, and power generation.

2.2 Ultrafiltration (UF) Systems

Complementing reverse osmosis, ultrafiltration systems employ membranes with larger pore sizes to remove macromolecules and suspended solids, enabling protection of RO membranes and enhancing overall system performance.

2.3 Electrodeionization (EDI) Systems

In applications requiring ultrapure water, EDI technology combines ion exchange resins and electricity to remove ionized species without chemical regenerants, supporting sustainable operation with minimal environmental impact.

2.4 Pretreatment and Softening Systems

Pretreatment, involving technologies like water softeners and media filters, ensures feed water quality optimal for downstream RO processes. Proper pretreatment prevents membrane fouling, extending operational lifespan and reducing maintenance costs.

3. Technological Innovations and Competitive Advantages

Recent years have seen substantial advancements in RO membrane materials, system automation, and energy recovery devices. Below is a comparison table highlighting benefits versus traditional water treatment methods:

| Feature | Traditional Treatment | Advanced Reverse Osmosis Systems |

|---|---|---|

| Removal Efficiency | Partial removal of dissolved solids and microbes | Up to 99% rejection of salts, bacteria, viruses |

| Energy Consumption | High due to chemical dosing and heating | Reduced by energy recovery turbines and optimized pumps |

| Environmental Impact | Chemical waste and sludge generation | Minimized chemical use and sustainable brine management |

| Operational Automation | Limited, manual operation prevalent | Advanced sensors, IoT-enabled monitoring, remote diagnostics |

| Membrane Life | Shorter due to scaling and fouling | Extended by enhanced pretreatment and membrane materials |

These innovations translate to measurable cost savings, higher water recovery ratios, and easier maintenance—a compelling value proposition for industrial clients where uptime and water quality are paramount.

4. Industry Positioning and Market Outlook

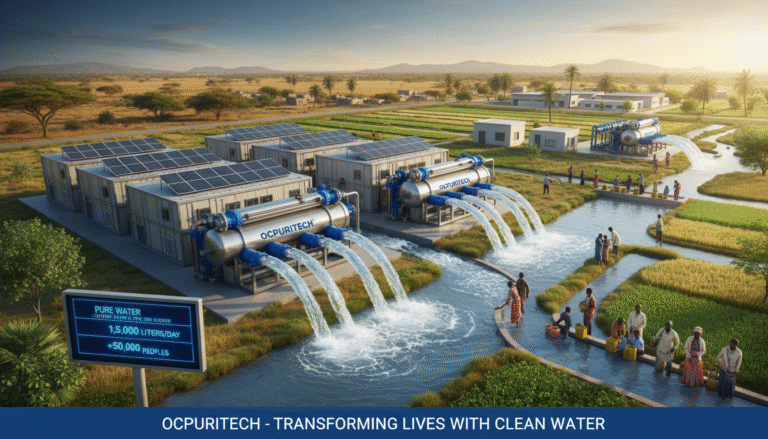

The global industrial water treatment market is expanding rapidly, with the reverse osmosis water system segment alone accounting for over 28% of market revenue in 2023. Asia Pacific leads with a dominant 38% share, reflecting intense investment in infrastructure and environmental regulations.

Commercial water treatment equipment growth is projected to add USD 31 billion between 2023 and 2028, driven by urbanization, water scarcity, and food safety standards. Whole house and point-of-entry systems incorporating RO technology also see rising adoption in residential-commercial hybrid applications. Industrial segments hold over 50% of the point-of-entry market revenue, emphasizing the multi-sector appeal of RO solutions.

5. Manufacturing and R&D Capabilities

Modern water treatment equipment manufacturers operate state-of-the-art production lines, featuring automated membrane fabrication, precision assembly of multi-stage filtration modules, and rigorous quality control adhering to ISO and NSF certifications.

R&D teams focus on membrane chemistry, system integration, and sustainable materials. Collaborative projects with universities and technology partners ensure continuous innovation. Pilot installations and field testing validate performance under diverse water qualities.

6. Customer Success Stories and Industry Applications

In one notable project, an industrial beverage producer replaced legacy filtration with a custom-built RO system, achieving 30% higher water recovery and reducing chemical consumption by 40%. System downtime dropped by 25%, thanks to remote monitoring and predictive maintenance features.

Another case involved a pharmaceutical facility using combined ultrafiltration and RO stages to meet ultrapure water standards, enabling compliance with stringent FDA requirements. The solution resulted in operational cost reductions and enhanced product quality, earning positive client feedback.

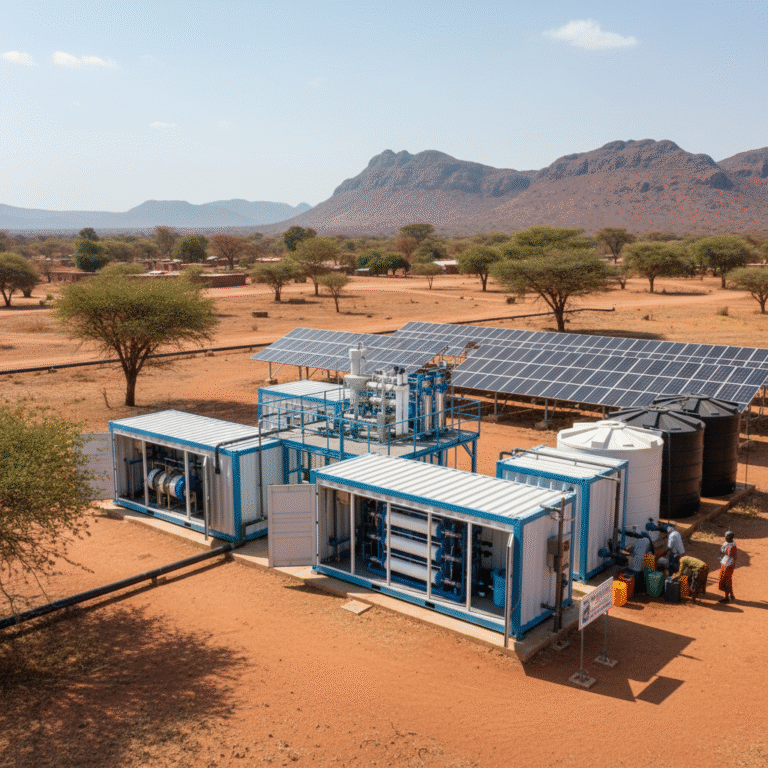

7. Commitment to Environmental Sustainability

Leading manufacturers incorporate green engineering principles by minimizing chemical inputs, maximizing water reuse, and using recyclable materials. Energy-efficient components reduce carbon footprints, supporting clients’ environmental goals.

Water treatment plants designed with reverse osmosis and complementary technologies not only safeguard public health but also protect aquatic ecosystems, helping industries meet evolving sustainability benchmarks.

8. Contact and Consultation: Your Next Step Toward Superior Water Quality

For enterprises seeking tailored water treatment solutions, comprehensive consultations are essential. Engage with expert teams specializing in reverse osmosis system design, customization, and integration.

Reach out via multiple channels to discuss your water quality challenges and receive detailed proposals aligned with your operational requirements and budget horizons. Early engagement ensures optimal system selection and smoother project execution.

Investing in advanced reverse osmosis water purification systems today equips your facility for tomorrow’s water demands efficiently and sustainably.

References:

- Grand View Research – Industrial Water Treatment Market (2024-2033)

- Grand View Research – Water Treatment Systems Market (2023-2030)

- Research and Markets – Commercial Water Treatment Equipment Market (2023-2028)