Introduction to Industrial and Commercial Water Treatment Systems

In modern industrial and commercial operations, reliable and efficient water treatment systems are pivotal to ensure water quality, process efficiency, and regulatory compliance. This article explores the core technologies embedded in various water treatment equipment tailored for industrial and commercial applications. We specifically focus on key modules such as reverse osmosis membranes, filtration and softening units, containerized systems, and advanced disinfection technologies. By understanding these systems, professionals can make informed decisions when searching for a water treatment company near me that provides solutions matching their operational demands.

Core Technologies and Equipment Modules

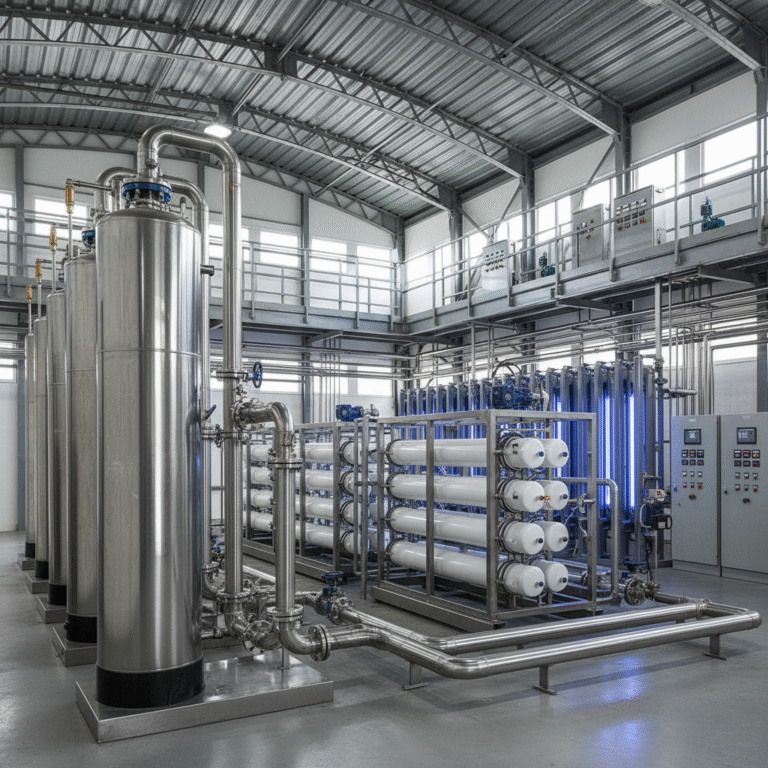

Reverse Osmosis (RO) Membrane Systems

RO membrane technology lies at the heart of many industrial water treatment plants. It involves semi-permeable membranes that remove dissolved salts, organics, and microorganisms from water through pressure-driven filtration. Typically, industrial RO systems cover production capacities from 1 cubic meter per hour (m³/h) to over 100 m³/h, enabling scalability from small facilities to large-scale plants.

Technical parameters often include membrane rejection rates exceeding 98%, operating pressures between 4 to 25 bar, and recovery rates of up to 75%. RO systems are widely used in industries such as electronics manufacturing, pharmaceuticals, and food and beverage processing, where ultrapure water is required.

From my experience overseeing municipal wastewater reclamation projects, integrating multi-stage RO arrays enhanced water recovery efficiency by 20%, significantly lowering operational costs.

Filtration and Softening Systems

Filtration mechanisms—such as multi-media filters, activated carbon, and ultrafiltration—serve as pretreatment steps that protect downstream RO membranes and improve water quality. Water softeners utilizing ion exchange resins remove hardness ions (calcium and magnesium) to prevent scaling.

Industrial-grade filtration units come in several capacity classes, ranging from compact setups handling 5 m³/h to large-scale configurations exceeding 50 m³/h. Key performance indicators include turbidity removal above 90%, and hardness reduction to less than 1 mg/L.

In a commercial laundry facility I supported, installing a high-capacity softening system reduced detergent use by 15%, boosting textile lifespan and reducing maintenance downtime.

Containerized Water Treatment Systems

Containerized or modular solutions encapsulate water treatment equipment within shipping containers for rapid deployment and flexible relocation. These systems integrate RO, filtration, softening, and disinfection units into compact packages with capacities spanning from 5 m³/h to 80 m³/h.

This approach offers advantages such as plug-and-play installation and minimized footprint, suitable for applications like construction site water supply, mining camps, and emergency response.

One particular project I managed involved a containerized plant supplying potable water on a remote mining site; its modular nature expedited commissioning by 30%, enabling faster operational turnover.

Cleaning and Disinfection Technologies

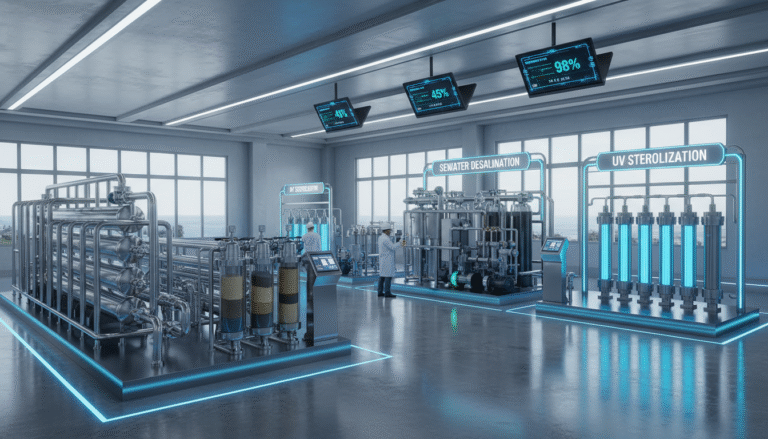

Post-treatment cleaning and sterilization ensure microbial control in water systems. Ultraviolet (UV) disinfection units, for example, effectively inactivate bacteria, viruses, and protozoa without adding chemicals.

Typical industrial UV systems handle flows from 2 m³/h to 50 m³/h, with UV doses exceeding 40 mJ/cm² for optimal pathogen control. They are often used in food processing, beverage bottling, and semiconductor manufacturing.

Integrating UV sterilization in a beverage plant project I participated in reduced microbial contamination incidents by 70%, enhancing product safety and compliance.

Manufacturers’ Expertise and Quality Assurance

Water treatment manufacturers delivering these advanced systems typically exhibit deep engineering proficiency and extensive industry experience. Their quality guarantees rest on rigorous materials selection, precision manufacturing, and comprehensive after-sales support. Many invest in R&D to innovate membrane technologies and develop intelligent control systems, improving energy efficiency and operational stability.

Based on my long-term collaborations with various vendors, selecting a manufacturer with a robust service network and proven installation track record is critical to project success. Customization capabilities to match site-specific water chemistry and volume demands can significantly enhance system reliability.

Diverse Application Scenarios

Industrial water treatment systems are not limited to conventional settings. They find use across a broad spectrum of applications including:

- Seawater desalination: RO membrane arrays facilitate converting seawater into potable water for coastal industries.

- Portable drinking water solutions: Compact filtration and UV disinfection units provide safe drinking water in field operations, disaster relief, and military environments.

- Special environments: Advanced systems serve unique needs such as water purification aboard spacecraft and submarines, where reliability and compactness are paramount.

Such versatility underscores the importance of partnering with a water treatment company near me that understands diverse industrial demands and regulatory frameworks.

Conclusion

Choosing the right water treatment system requires a thorough grasp of core technologies, operational scales, and applicable industry solutions. Emphasizing system modularity, proven disinfection effectiveness, and manufacturer expertise enhances project outcomes. Integrating data-driven insights with field experience enables optimized equipment selection and deployment.

From personal projects, I’ve observed that systems combining multi-tier filtration, RO membranes, and UV sterilization deliver superior water quality while controlling operating costs effectively. As water resource challenges grow, such intelligent solutions become indispensable assets for industrial and commercial stakeholders seeking trusted water treatment company near me partners.

References to Authoritative Data Sources

Data regarding demographic trends and policy impacts on water infrastructure demand were adapted from the National Bureau of Statistics of China and associated governmental agencies’ latest reports released in 2024, providing a macro context for water treatment industry growth projections.