In today’s industrial landscape, access to ultra-pure and efficiently treated water is more crucial than ever. Industrial processes demand water treatment solutions that not only ensure regulatory compliance but also optimize operational efficiency and environmental sustainability. Over the past 14 years, I have witnessed the transformative impact of high-performance water treatment systems on various industries worldwide, especially in emerging markets like Southeast Asia, Africa, and South America.

Understanding the critical role that industrial water purification plays, companies have developed comprehensive equipment portfolios combining cutting-edge technology with robust manufacturing capabilities. This article delves deep into the nuances of industrial water treatment, highlighting core equipment types, their technical merits, market dynamics, and practical insights from successful implementations.

The Industrial Water Purification Landscape and Company Expertise

Industrial water treatment is key to ensuring process water quality, minimizing environmental impact, and meeting stringent discharge standards. It encompasses removing contaminants such as dissolved solids, organics, heavy metals, and microorganisms to produce water fit for applications ranging from boiler feedwater to pharmaceutical manufacturing.

Our company, established over a decade ago, operates two standardized factories covering more than 10,000 square meters in Guangzhou and Jiangmen. With a mission to make clean, high-quality water accessible globally, we specialize in designing and manufacturing state-of-the-art water purification equipment tailored to challenging industrial scenarios. This includes systems for seawater desalination, brackish water treatment, and ultrapure water generation, supporting industries such as agriculture, healthcare, food and beverage processing, pharmaceuticals, and laboratories.

Environmental sustainability remains at the core of our philosophy. We actively pursue innovations in membrane technology and system integration to reduce energy consumption and chemical usage, thus aligning operational efficiency with ecological responsibility. As Mrs. Carrie Chan, our owner, expresses, “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.”

Advanced Product Portfolio for Industrial Water Treatment

Our comprehensive product line reflects decades of expertise in membrane filtration and water purification. Key systems include:

- Remote Control Reverse Osmosis (RO) Systems — Designed for both brackish and seawater desalination, these systems feature automated control panels, advanced energy recovery devices, and robust membranes certified under NSF/ANSI 58 standards, guaranteeing at least 75% reduction of total dissolved solids (TDS) and efficient recovery rates exceeding 30%.

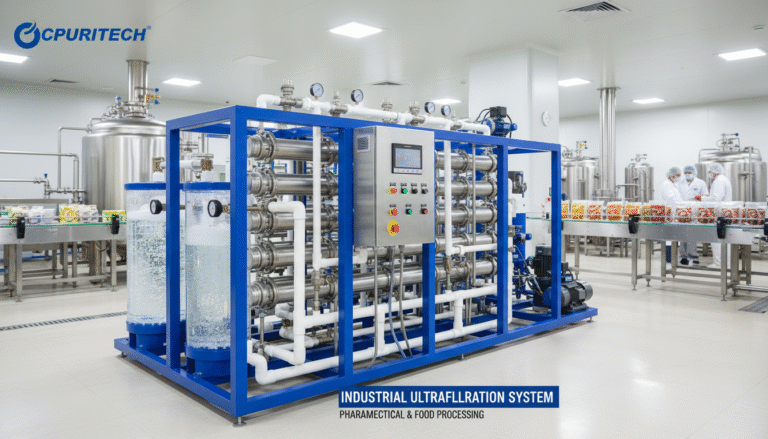

- Ultrafiltration (UF) Systems — Offering lower energy consumption due to reduced operating pressures, UF membranes serve as effective pretreatment units to protect downstream RO modules. Our ultrafiltration units excel in removing suspended solids, bacteria, and macromolecules, enhancing overall system longevity and water quality.

- Nanofiltration (NF) Systems — With membrane pore sizes between 1-10 nm, NF membranes efficiently remove divalent and multivalent ions, pesticides, herbicides, and larger organic molecules. These systems strike a balance between high contaminant rejection and moderate energy use, suitable for industries requiring selective ion removal.

- Electrodeionization (EDI) Ultrapure Water Systems — Combining ion-exchange resins with electricity, EDI modules produce ultrapure water without chemical regenerants. These are ideal for sensitive pharmaceutical or electronics manufacturing processes demanding consistently high water purity without producing hazardous waste.

- Pretreatment Units — Sand filters, activated carbon filters, and water softeners form essential pretreatment layers that protect membranes from fouling and scale formation, ensuring longer equipment lifespan and stable operation.

In one of my recent projects for a beverage bottling facility in Southeast Asia, implementing an integrated RO-UF-EDI water treatment train resulted in a 40% reduction in wastewater discharge and a 15% drop in energy consumption compared to their former treatment setup. This exemplifies how combining multiple technologies tailored to specific industrial needs drives operational benefits.

Technological Innovations and Competitive Edge

Continuous industrial progress demands innovation in water treatment solutions. Our product line features several advanced technologies that position us distinctively in the market:

- Energy Recovery Devices (ERDs) integrated in desalination systems reduce specific energy consumption by reclaiming hydraulic energy from high-pressure brine streams.

- Smart Remote Monitoring and Control enable real-time system diagnostics and preventive maintenance alerts, reducing operational downtime.

- Advanced membrane materials engineered for fouling resistance and enhanced permeability extend service intervals and improve recovery rates.

To better visualize these advantages, the following table compares different membrane filtration technologies used in industrial water treatment:

| Technology | Operating Pressure | Energy Consumption | Contaminant Removal Efficiency | Typical Applications |

|---|---|---|---|---|

| Ultrafiltration (UF) | Low (1-3 bar) | Low | Suspended solids, bacteria, macromolecules | Pretreatment, surface water |

| Nanofiltration (NF) | Medium (4-12 bar) | Moderate | Divalent ions, organics, pesticides | Softening, color removal, partial desalination |

| Reverse Osmosis (RO) | High (8-15 bar) | High (but with ERDs reduced) | Monovalent ions, salts, dissolved solids | Desalination, ultrapure water |

This comparison underscores the importance of carefully selecting membrane technologies based on specific water quality challenges and energy budgets, especially in cost-sensitive emerging markets.

Global Market Trends and Regional Industrial Applications

Market research indicates rapid growth in the industrial water treatment equipment sector, targeted to expand from USD 26.5 billion in 2025 to USD 41.8 billion by 2034 at a CAGR of 5.2%. This surge is fueled by escalating freshwater scarcity, stringent environmental regulations, and rising demand for ultra-pure water in sectors like pharmaceuticals, electronics, and food processing.

Emerging regions such as Africa, Southeast Asia, and South America are focal points for this expansion due to their tightening pollution controls and infrastructural modernization efforts. However, challenges including high capital expenditures, membrane fouling, sludge handling, and skilled operation shortages influence solution adoption.

In our experience, tailoring solutions to meet these local constraints has been key. For example, a brackish water RO installation in a South American mining operation leveraged modular, skid-mounted units to simplify onsite assembly and reduce installation time by 30%. Additionally, proactive membrane selection and pretreatment design minimized fouling, resulting in a 25% decrease in operational costs.

Such regional insights align with findings from industrial water treatment equipment market studies, emphasizing adaptive strategies for future-proofing investments while ensuring compliance and sustainability.

Manufacturing Excellence and Research Capabilities

Our manufacturing operations leverage two strategically located factories outfitted with advanced CNC machining, automated assembly lines, and stringent quality control systems. Each product undergoes rigorous testing protocols including pressure integrity, flow performance, and contaminant rejection efficiency.

A dedicated R&D team collaborates with membrane manufacturers, regulatory bodies, and end-users to continuously improve system designs, develop custom configurations, and optimize treatment processes. This synergy has led to innovations such as low-fouling membrane coatings and multifunctional filtration modules that reduce footprint without compromising capacity.

The integration of these capabilities ensures that our water treatment solutions are not only high-performing but also reliable and user-friendly, addressing diverse industrial needs while fostering trust and longevity.

Real-World Applications and Customer Success Stories

Several recent projects illustrate the practical benefits of deploying tailored water treatment systems in industrial settings:

- At an agricultural plantation in Africa, a seawater desalination system combined with nanofiltration pretreatment provided a reliable freshwater source improving irrigation efficiency by 35%, even during drought periods.

- In a pharmaceutical manufacturing facility in Asia, the adoption of an integrated ultrafiltration and EDI ultrapure water system reduced chemical usage by 50% compared to traditional ion-exchange, enhancing product quality consistency.

- A beverage processing plant in South America implemented a remote-controlled reverse osmosis system with real-time monitoring, leading to a 20% reduction in downtime and overall water consumption decrease by 18% within six months.

These case studies demonstrate the tangible value of combining proven technologies with localized engineering and proactive service support, driving both sustainability and profitability.

Commitment to Environmental Sustainability and Future Outlook

Beyond delivering premium water quality, our commitment to green manufacturing processes and energy-efficient technology development is unwavering. Membrane systems with extended service life and integrated recovery methods lower carbon footprints and reduce waste generation.

We consistently explore eco-friendly materials and solutions to address sludge disposal and chemical footprint challenges, particularly relevant for markets with emerging environmental regulations.

Looking ahead, the convergence of digital technologies and membrane innovations will reshape industrial water treatment. Embracing smart sensors, AI-driven analytics, and modular scalable designs will enable more responsive, cost-effective, and sustainable water purification aligned with global industrial growth aspirations.

As the industrial water treatment market continues its robust expansion, especially in regions like Africa, Southeast Asia, and South America, companies equipped with advanced systems and responsive service models will lead the way in guaranteeing reliable and clean water supplies.

How to Engage with Customized Industrial Water Treatment Solutions

We encourage industrial operators and technical procurement teams looking for high-performance water treatment solutions to connect with experienced providers who understand regional challenges and can deliver tailored systems. Whether your requirements involve seawater desalination, brackish water treatment, or ultrapure water for pharmaceuticals, solutions exist to enhance productivity and regulatory compliance.

Engage through multiple channels for personalized consultations, on-site assessments, or pilot projects that validate system efficacy under your operational conditions. Our team’s expertise covering equipment, installation, and lifecycle support ensures seamless integration and sustained performance.

By adopting innovative water treatment technologies today, industries can secure water reliability, reduce operational costs, and contribute to global environmental stewardship.

FAQ

Q1: What are the primary benefits of using reverse osmosis in industrial water treatment?

Reverse osmosis systems provide high contaminant removal efficiency, reducing TDS by over 75%, improving water quality for industrial use and helping meet regulatory standards.

Q2: How does ultrafiltration compare to nanofiltration in energy consumption?

Ultrafiltration generally operates at lower pressures and consumes less energy than nanofiltration, making it a cost-effective pretreatment method.

Q3: What industries can benefit most from electrodeionization (EDI) systems?

EDI systems are ideal for industries requiring ultrapure water such as pharmaceuticals, electronics manufacturing, and laboratory applications.

Q4: How important is pretreatment in an industrial water treatment system?

Essential for protecting membranes from fouling and scaling, pretreatment extends system lifespan and enhances overall efficiency.

Q5: What are common challenges in industrial water treatment in emerging markets?

Challenges include high capital and operational costs, membrane fouling, sludge disposal issues, and scarcity of skilled operators.

Q6: How do energy recovery devices (ERDs) contribute to system efficiency?

ERDs reclaim energy from high-pressure brine streams, significantly reducing energy consumption in desalination systems.

Q7: Can water treatment equipment be customized for different industrial applications?

Yes, systems can be tailored regarding membrane choice, process configuration, and automation to suit specific water quality and operational demands.

Q8: What environmental benefits arise from using advanced water treatment systems?

Benefits include reduced wastewater discharge, lower chemical use, energy savings, and mitigating environmental pollution.

Q9: How does real-time remote control improve industrial water treatment operations?

Remote monitoring enables early detection of issues, proactive maintenance, and minimizes downtime, enhancing reliability.

Q10: What is the future outlook for industrial water treatment markets?

The sector is poised for growth driven by stricter environmental regulations, technological advancements, and expansion in emerging economies demanding sustainable water solutions.