How Does Machinery Required for Water Treatment Plant Boost Community Health?

Access to clean and safe drinking water is a cornerstone of community health and economic development. In many regions worldwide, particularly those facing water scarcity and pollution challenges, the integration of advanced machinery required for water treatment plant plays a pivotal role in improving public health outcomes. Properly designed and equipped water treatment plants not only ensure the removal of harmful contaminants but also provide reliable water sources that support hygiene, reduce waterborne diseases, and stimulate local economies.

The importance of water treatment infrastructure is underscored by alarming global statistics: billions still lack safely managed drinking water services, contributing significantly to disease burdens. Applying specialized equipment and systems tailored to regional water quality challenges is therefore essential. From filtration to disinfection technologies, the machinery involved transforms raw, often contaminated water into potable water compliant with stringent health standards.

Comprehensive Overview of Water Treatment Plant Machinery and Technologies

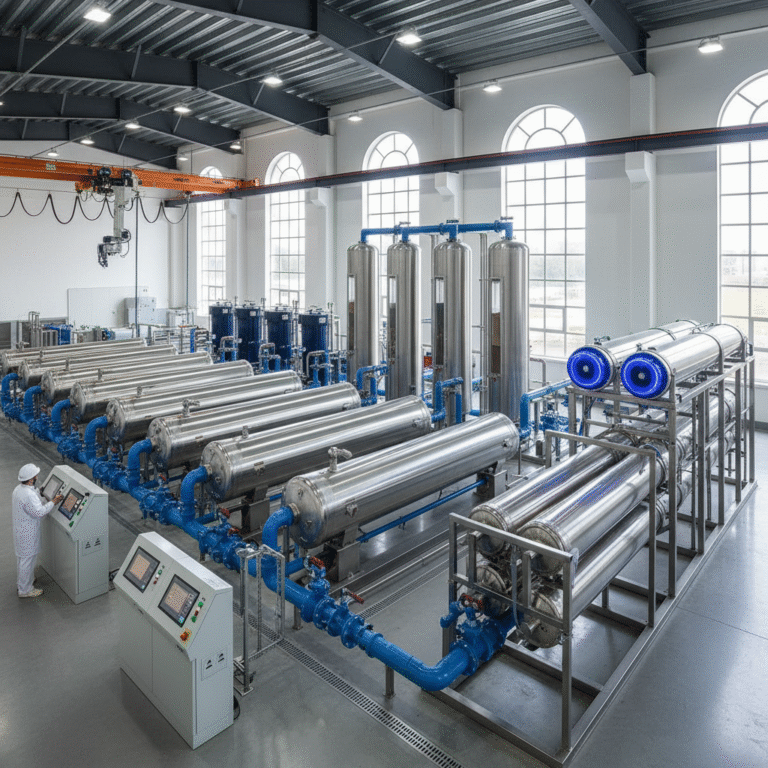

Water treatment plants employ a series of sophisticated machinery and equipment designed to address various contaminants and make water safe for consumption. The core equipment usually includes:

- Pre-treatment units: These typically involve screens, grit chambers, and sedimentation tanks that remove large debris and suspended solids to prevent damage to subsequent machinery.

- Filtration systems: Technologies such as sand filters, activated carbon filters, ultrafiltration (UF), and membrane filtration systems, including reverse osmosis (RO), efficiently remove particulate matter, organic compounds, and some pathogens.

- Disinfection units: UV disinfection, chlorination, ozone treatment, and advanced oxidation processes serve to inactivate or destroy microorganisms.

- Softening and chemical dosing equipment: These systems adjust water hardness and add chemicals for coagulation, flocculation, or pH control to enhance treatment effectiveness.

- Automation and monitoring: Modern plants integrate smart control systems for real-time monitoring, process optimization, and autonomous operation, enhancing reliability and reducing operational costs.

Each machinery component’s selection depends on source water quality, capacity requirements, and targeted water standards. For instance, membrane-based technologies like RO are particularly effective in removing dissolved salts and microbes but require careful pretreatment to avoid fouling. Meanwhile, UV disinfection offers chemical-free pathogen control suitable for small to medium scale plants.

Regional Water Resource Challenges and Market Demand

Many developing regions face acute water shortages exacerbated by climate variability, pollution from industrial and agricultural activities, and rapid urbanization. For example, water-scarce countries encounter both quantitative and qualitative challenges in meeting community needs. Contaminants such as pathogens, heavy metals, and organic pollutants jeopardize health and limit potable water availability.

In such contexts, investment in state-of-the-art machinery required for water treatment plant becomes not only essential but also urgent. The market for water purification is expanding rapidly driven by these needs. According to a 2023 study from Market Research Future, the global water purifier market is projected to grow at a 13.86% CAGR through 2032, highlighting governmental initiatives and increased awareness about waterborne diseases as key drivers.

Furthermore, industrial and commercial sectors in these regions demand reliable water treatment solutions to comply with regulations and sustain operational integrity. The industrial water purification market is expected to exceed $15 billion by 2032, incorporating technologies such as membrane filtration and chemical treatment tailored to distinct process water needs.

Drinking Water Plant Standards and Treatment Processes

Water treatment plants must comply with stringent standards established by both local regulatory bodies and international authorities such as the World Health Organization (WHO). These ensure treated water is free from pathogens, harmful chemicals, and turbidity, minimizing health risks.

The treatment process in a typical community water plant generally includes:

- Intake and screening: Raw water is captured and pre-filtered to remove coarse materials.

- Coagulation and flocculation: Chemicals are added to aggregate fine particles into larger flocs for easier removal.

- Sedimentation: Flocculated particles settle out in clarifiers.

- Filtration: Water passes through granular filters or membranes removing residual suspended solids.

- Disinfection: Pathogens are inactivated using UV light, chlorination, or ozone.

- Post-treatment conditioning: The water’s pH and mineral content may be adjusted to meet taste and health criteria.

Advanced monitoring systems integrated within the treatment plant continuously verify water quality compliance and enable rapid response to any deviations, ensuring the safety of end-users.

Tailored Solutions and Engineering Design

Every community has unique water challenges and volume demands, requiring customized water treatment solutions. When designing these systems, engineers consider the local water quality, population size, and intended use—from household consumption to industrial processes.

For example, in a medium-sized community I worked with, we implemented a water treatment system combining coagulation, ultrafiltration membranes, and UV disinfection. The pre-treatment equipment was specially designed to handle high turbidity due to seasonal rains. Additionally, we incorporated automated chemical dosing and real-time water quality sensors to optimize treatment parameters daily.

This tailored design improved water clarity by 98%, reduced microbial contamination to undetectable levels, and lowered overall operational costs by 15% compared to traditional setups.

On a larger scale, advanced supervisory control and data acquisition (SCADA) systems are employed for facilities servicing multiple districts. Such systems allow for remote plant management, early fault detection, and predictive maintenance—which are crucial in resource-constrained regions to ensure uninterrupted water supply.

Real-World Applications and Impact on Community Health

Over the years, I have witnessed how machinery required for water treatment plant directly transforms community wellbeing:

- Case 1: In a drought-prone region, installation of a modular membrane-based water treatment plant reduced waterborne disease incidence by 40% within 18 months, according to local health data. The machinery’s robustness and low maintenance needs were vital for sustained operation despite harsh environmental conditions.

- Case 2: A rural community benefited from an integrated water softening and UV disinfection system, improving water taste and microbial safety. Community reports indicated a marked decline in diarrheal diseases, improving school attendance rates by 10%.

- Case 3: Industrial clients in emerging economies investing in chemical dosing and reverse osmosis machinery experienced improved process water quality, reducing operational downtime and regulatory penalties by over 20%, which indirectly contributed to local employment stability.

These examples highlight how appropriately configured water treatment machinery not only meets technical water safety requirements but also yields tangible social and economic benefits.

Conclusion and Call to Action

Reliable drinking water is critical for healthy communities and sustainable development. The machinery required for water treatment plants—from screening and filtration to advanced disinfection and automation—is at the heart of ensuring water safety globally. Integrating proven equipment, tailored designs, and real-time monitoring systems offers an effective pathway to combat waterborne diseases, improve public health, and foster economic resilience.

If your community or enterprise is considering upgrading or establishing water treatment infrastructure, collaborating with experienced engineers and leveraging state-of-the-art machinery is essential. Reach out to specialized consultants to design solutions that meet your specific water quality challenges and regulatory requirements. Together, we can build water systems that support healthier lives and thriving communities.

Information synthesized with insights from Market Research Future (MRFR) reports on water purifier and industrial water purification markets (2023), the National Alliance for Water Innovation (NAWI) research updates (2025), and WHO’s guidelines on safe drinking water (2023).