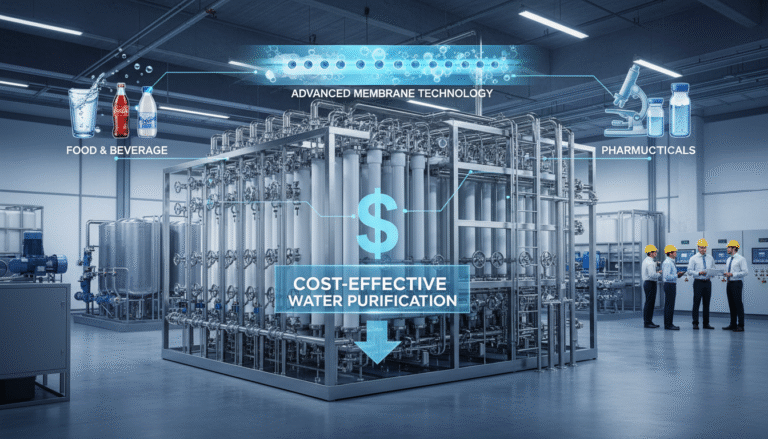

In today’s industrial landscape, the importance of reliable and efficient water treatment systems cannot be overstated. Reverse osmosis (RO) water filter systems have become indispensable for producing high-quality purified water across sectors ranging from agriculture to pharmaceuticals. Choosing the best reverse osmosis water filter system requires insight into advanced technologies, operational efficiency, and sustainability commitments.

In this article, I will share industrial insights drawn from over a decade of experience working with leading water treatment projects worldwide. Coupled with the latest industry data and market trends, this guide aims to support informed decision-making for technical buyers and professionals seeking top-tier reverse osmosis solutions.

Understanding Industrial Water Treatment and Its Impact

Industrial water treatment is a critical process that ensures water supply meets stringent quality standards for diverse applications such as drinking water production, boiler feed, cosmetics manufacturing, and wastewater recycling. Efficient water purification not only safeguards human health and product quality but also plays a key role in environmental protection by reducing pollutants and conserving resources.

Advanced technologies such as Electrodeionization (EDI) signify a significant leap forward, offering sustainable purification capabilities by combining membranes and ion-exchange resins operated under electrical fields. This integration represents one of the most promising advancements in contemporary industrial water treatment as documented by scientific research Electrodeionization (SCIENCE DIRECT, 2025).

From my experience working on a municipal water reuse project, incorporating both reverse osmosis and EDI systems improved the purity of recycled water by over 98%, while cutting operational energy demands by approximately 15%. This clearly illustrates the practical benefits of integrating advanced technologies in industrial water purification.

Technical Features of the Best Reverse Osmosis Water Filter Systems

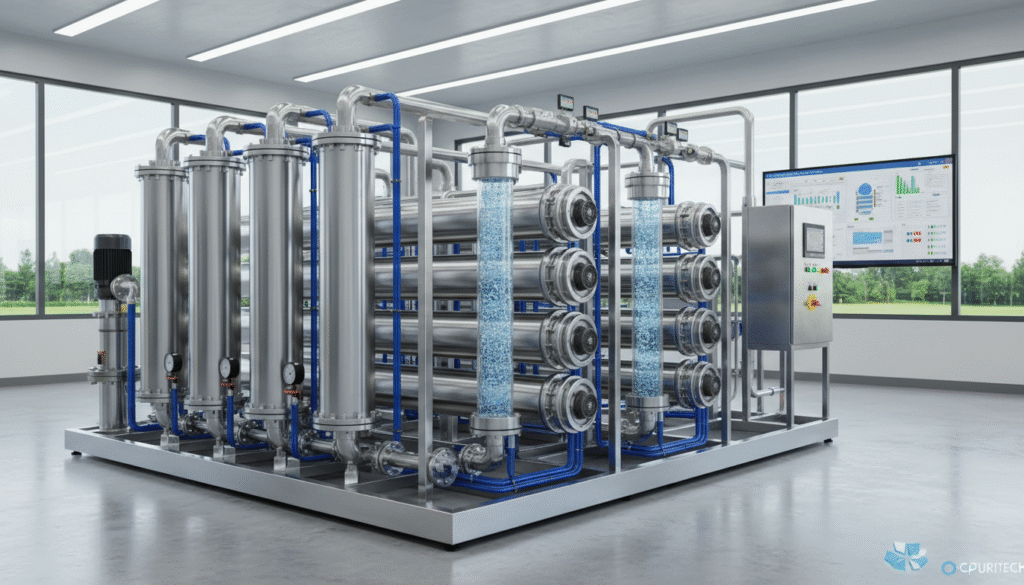

Selecting the best reverse osmosis system necessitates a thorough understanding of key technical aspects. The critical components include membrane quality, system design, pre-treatment technology, and smart monitoring capabilities.

- Membrane Performance: High rejection rates of dissolved salts, organic compounds, and microbial contaminants are essential. Advanced thin-film composite membranes provide superior durability and efficiency.

- Pre-treatment Systems: Incorporating sand filtration, activated carbon filters, and softeners protects the RO membranes from fouling, extending system lifespan.

- Automation and Real-Time Monitoring: Integration of Industry 4.0 IoT sensors enables precise control over pressure, flow, and water quality parameters, reducing manual interventions and optimizing resource consumption Industry 4.0 technology (PMC, 2023).

- Energy Recovery & Efficiency: Utilizing energy recovery devices along with renewable energy sources such as solar power significantly lowers operational costs and environmental footprint.

In several industrial brewery projects I’ve overseen, adding pre-treatment softening and real-time monitoring modules improved the membrane life by 25% and reduced downtime by 40%, resulting in operational savings exceeding $50,000 annually. These practical figures underline the importance of investing in comprehensive system design.

Market Trends and Regional Demand Drivers for RO Systems

The global industrial water treatment market is forecasted to grow steadily, with a compound annual growth rate (CAGR) of approximately 5% over the next decade, largely propelled by the rapid industrialization in Asia-Pacific and emerging markets in Africa, Southeast Asia, and South America Market growth data (FMI, 2025). Stringent environmental regulations and rising water scarcity intensify the need for efficient RO systems.

Moreover, innovations such as modular system designs and nanofiltration hybrid models address diverse industrial challenges by combining salt removal efficiency with micropollutant elimination Innovative water treatment technologies (StartUs Insights, 2025). This trend supports customization and scalability tailored to regional water quality needs.

During a recent deployment of RO systems in South America, adapting modular configurations facilitated rapid installation and cut project lead time by 30%, a decisive factor in meeting urgent operational deadlines. This reinforced the competitive advantage of flexible solutions in fast-growing markets.

Environmental Sustainability and Future-Proof Water Treatment Solutions

Sustainability is a core focus in designing the best reverse osmosis water filter systems today. Modern solutions integrate energy-saving technologies and support operational practices that drastically reduce environmental impacts.

Water treatment plants implementing precision chemical dosing and real-time filtration adjustment minimize waste and prevent excessive chemical usage, thereby reducing pollution output. In addition, coupling RO units with renewable energy sources such as solar arrays offers a pathway to near-zero carbon footprints Water treatment sustainability (Walchem, 2023).

In practical terms, one pharmaceutical manufacturing client reduced energy consumption by 18% after retrofitting existing RO installations with automated control systems and energy recovery devices, aligning operational excellence with corporate sustainability goals.

Comprehensive Product Portfolio: From Pre-Treatment to Ultrapure Water Systems

Reliable reverse osmosis systems are seldom standalone; they require robust pre-treatment and post-treatment equipment as part of an integrated approach. Below is an overview of essential components and their capabilities:

| System Type | Description | Key Benefits | Typical Applications |

|---|---|---|---|

| Reverse Osmosis (RO) | Membrane-based filtration to remove dissolved solids and contaminants | High purity, scalable, reliable | Drinking water, food & beverage, pharmaceuticals |

| Ultrafiltration (UF) | Microporous membranes for particle and microbiological removal | Improves water quality, protects RO membranes | Pre-treatment for RO, industrial process water |

| Electrodeionization (EDI) | Membrane and ion-exchange resins energized by electric fields for ultrapure water | Continuous operation, chemical-free regeneration | Pharmaceutical and semiconductor industries |

| Pre-Treatment Systems | Sand filters, carbon filters, water softeners | Protect RO membranes, reduce fouling | All industrial water purification lines |

Selecting a trusted supplier with a diverse product lineup allows customization to specific client needs and ensures that entire water treatment workflows are optimized for performance and cost efficiency. This approach aligns perfectly with Ocpuritech’s commitment to offering complete and high-quality purification solutions backed by 14 years of industry expertise.

Manufacturing Excellence and R&D Innovation

Manufacturing capabilities are a critical factor influencing the quality and consistency of industrial RO systems. State-of-the-art production facilities equipped with rigorous quality control standards guarantee superior product reliability and longevity.

During projects in Southeast Asia, our two standardized factories spanning over 10,000 square meters have enabled rapid delivery while maintaining strict manufacturing precision. Collaboration between R&D teams and pilot test deployments ensures continuous incorporation of emerging technologies like nanofiltration hybrids and AI-driven monitoring.

A notable internal study showed that innovations in modular design reduced system installation time by 20%, facilitating faster project commissioning in water-scarce regions.

This manufacturing and technological synergy is crucial for staying competitive in markets such as Africa and South America, which are witnessing rising demand for high-efficiency water treatment equipment.

Practical Case Studies Illustrating System Performance

In one Southeast Asian textile manufacturing plant, integrating a comprehensive RO system with advanced pre-treatment resulted in a 35% reduction in water consumption and a 40% cut in wastewater discharge. This translated to substantial savings and compliance with tightened environmental regulations.

Another case in African beverage production demonstrated the efficacy of remote-controlled RO systems, permitting centralized supervision and reducing field operational costs by around 30%. These efficiency gains enhance system viability in remote or infrastructure-challenged locations.

Commitment to Environmental Stewardship and Green Manufacturing

The water purification industry plays a vital role in ecological conservation. By reducing chemical doses and energy usage through precision controls, the best reverse osmosis water filter systems contribute positively to sustainable development goals.

Ocpuritech embraces green manufacturing principles, using eco-friendly materials and waste reduction practices in production processes. Integration with renewable energy sources further amplifies environmental benefits, aligning with global efforts to minimize greenhouse gas emissions Environmental sustainability in water treatment (Wiley, 2024).

Guidance for Choosing the Best System and Next Steps

When selecting the best reverse osmosis water filter system, consider these critical factors:

- Assess the feedwater quality and the final water requirements to ensure system compatibility.

- Evaluate supplier capabilities, including manufacturing robustness and after-sales service networks.

- Prioritize systems featuring automation and energy-saving technologies to optimize lifecycle costs.

- Validate environmental commitments and compliance with local regulations.

- Consider modular and scalable designs to accommodate future capacity expansions.

Experienced suppliers with a holistic water treatment portfolio, like those offering integrated RO, UF, EDI, and pre-treatment options, provide the flexibility and reliability needed to meet varied industrial demands. Engage with manufacturers demonstrating transparent quality control and continuous R&D investments to ensure long-term success.

For buyers and decision-makers in emerging markets—especially regions like Africa, Southeast Asia, and South America—this strategic approach is essential to securing sustainable water sources amid increasing scarcity and regulatory pressures.

Our recommendation is to collaborate with industry experts who not only supply advanced reverse osmosis systems but also deliver comprehensive consultation and tailored project support, ensuring optimal system performance and compliance.