Judging Impact? Can RO Water Treatment Process Upgrade Industry?

In recent years, the industrial landscape has seen a significant shift toward sustainable and efficient water management practices. Among the various technologies available, the RO water treatment process stands out as a critical enabler of this transformation. This article explores how reverse osmosis (RO) technology elevates industrial operations, highlighting technological innovations, market growth, and real-world case studies that underline its industry-wide impact.

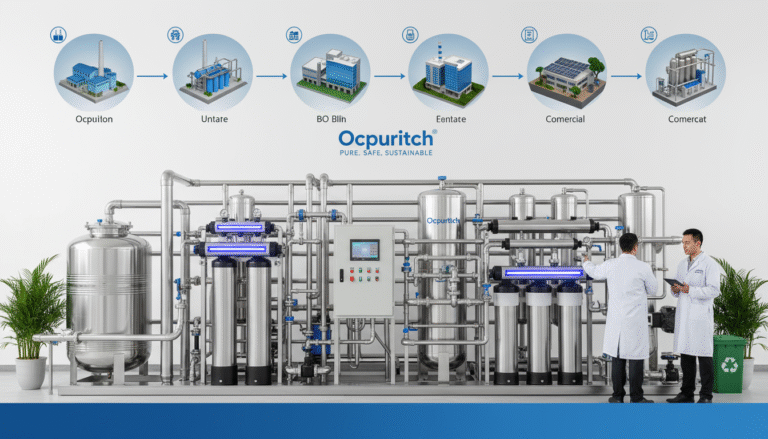

1. Industry Context and The Increasing Role of RO Water Treatment

The demand for ultra-pure water has surged across industries such as power generation, semiconductor manufacturing, food and beverage processing, and pharmaceuticals. This trend stems from the need to optimize product quality, comply with stringent environmental regulations, and reduce operational costs linked to inefficient water use.

RO water treatment process is central to addressing these challenges. It uses semipermeable membranes to remove dissolved salts, organic molecules, and microorganisms, delivering high-purity water essential for sensitive industrial processes. The technology’s growing adoption marks an important milestone in industrial water management and environmental stewardship.

2. Product Suite: Comprehensive Water Treatment Solutions

Advanced water treatment manufacturers provide integrated solution suites that often include:

- Reverse Osmosis (RO) Systems: Featuring high-rejection membranes, these systems effectively remove up to 99% of dissolved solids and contaminants. Typical operating pressures range between 200-600 psi, with recovery rates optimized up to 85%, varying by feed water quality.

- Ultrafiltration (UF) Systems: Acting as pretreatment to RO or standalone units, ultrafiltration membranes filter out suspended solids, colloidal particles, and bacteria, ensuring longer RO membrane life and stable operation.

- Electrodeionization (EDI) Units: Used post-RO for ultrapure water, EDI systems remove ionic impurities without chemical regenerants, ensuring continuous high purity with lower operational costs.

- Water Softening and Pretreatment Systems: These include multimedia filters, activated carbon filters, and ion-exchange softeners designed to reduce scale-forming ions and organics that compromise downstream membranes.

Each system is tailored to industry-specific parameters. For instance, power plants prioritize silica and hardness removal; microelectronics sectors focus on extremely low total dissolved solids (TDS); and food manufacturers emphasize sanitary design and regulatory compliance.

3. Technological Innovations Driving Competitive Advantages

Modern RO water treatment process systems feature several cutting-edge innovations:

| Feature | Traditional Methods | Advanced RO Systems | Impact |

|---|---|---|---|

| Membrane Materials | Cellulose acetate, prone to biofouling | Thin film composite membranes with anti-fouling coatings | Longer membrane lifespan; reduced downtime |

| Energy Consumption | High-pressure pumps with low efficiency | Energy recovery devices & variable frequency drives | Up to 30% energy savings; lower OPEX |

| Automation & Monitoring | Manual controls, limited process feedback | Real-time sensors, PLC & remote monitoring | Optimized performance; predictive maintenance |

| Waste Brine Management | Direct discharge with environmental concerns | Zero liquid discharge (ZLD) integration | Regulatory compliance; water reuse |

These innovations not only improve purification efficiency but also align with sustainability goals, setting manufacturers apart in a competitive global market.

4. Market Trends and Industry Outlook

According to Archive Market Research, the commercial and industrial RO water treatment equipment market is projected to reach approximately $12.5 billion by 2025, growing at a Compound Annual Growth Rate (CAGR) of 8.5% from 2025 to 2033. This robust market expansion is primarily driven by increasing industrial demand for ultrapure water critical to operational efficiency, product quality, and regulatory compliance across power, electronics, food and beverage, and pharmaceutical sectors.

Environmental awareness and stricter wastewater regulations further stimulate investments in advanced water treatment technologies. The integration of energy-efficient designs and novel membrane materials supports cost reduction while improving performance.

This macro-level trend indicates a strong industrial shift towards adopting RO water treatment processes as a key operational upgrade, enhancing competitive advantage.

5. Manufacturing Excellence and R&D Capabilities

Leading manufacturers leverage advanced production facilities equipped with ISO-certified quality controls to ensure consistent membrane performance. State-of-the-art pilot plants enable rapid prototyping and testing of new membrane formulations and system configurations.

Research and development teams work collaboratively with academic institutes and environmental agencies to pioneer innovations such as biodegradable membranes and real-time fouling detection systems, shaping the future of sustainable water treatment.

Such capabilities not only guarantee reliability but also accelerate the customization of solutions for diverse industrial challenges, shortening time to deployment.

6. Practical Case Studies from the Field

Drawing from my extensive consulting experience in industrial water treatment:

- Case 1 – Power Generation Facility: At a coal-fired plant, implementing a multi-stage RO system reduced silica content from 150 ppb to under 10 ppb. This improvement extended turbine lifespan by 25% and decreased unplanned outages by 15%, resulting in an ROI within 18 months.

- Case 2 – Semiconductor Manufacturer: Upgrading to an advanced RO-EDI sequence helped meet ultra-pure water (UPW) standards essential for wafer fabrication. Water resistivity increased to 18 MΩ·cm, minimizing defects and boosting yield rates by approximately 8%.

- Case 3 – Food Processing Plant: Installing a combined ultrafiltration and RO system improved product consistency and ensured compliance with hygienic standards. The plant reported a 20% reduction in water usage following system commissioning.

These examples underscore how tailored RO solutions drive measurable improvements in operational efficiency, cost savings, and regulatory compliance.

7. Commitment to Environmental Sustainability

Adopting advanced RO water treatment processes aligns closely with corporate social responsibility agendas. Key sustainability benefits include:

- Reduction in freshwater withdrawal by enabling water reuse and recycling

- Lower chemical consumption relative to traditional treatment methods

- Minimized pollutant discharge through precise contaminant removal and brine management

- Energy-efficient system designs contributing to reduced carbon footprints

Manufacturers increasingly embed green manufacturing practices, including renewable energy utilization and waste valorization, highlighting a holistic approach to eco-friendly industrial water management.

8. Next Steps for Interested Stakeholders

For industrial players seeking to upgrade their water treatment infrastructure, partnering with experienced RO system providers is crucial. Comprehensive assessments, pilot testing, and customization ensure alignment with specific process demands and budget considerations.

Engaging early with technical consultants can clarify long-term benefits such as minimized downtime, regulatory adherence, and cost savings from reduced energy and water consumption.

To explore tailored RO water treatment process solutions, I encourage stakeholders to reach out via technical consultation forms, scheduled webinars, or direct dialogue with solution experts.

Conclusion

The evolution of the RO water treatment process reflects a broader industrial upgrade agenda focused on efficiency, quality, and sustainability. Backed by strong market growth data and validated by hands-on success stories, RO technology emerges as a cornerstone of modern industrial water management. Embracing this technology not only enhances operational outcomes but also supports global environmental imperatives.

References

Data cited is based on the report by Archive Market Research titled “Commercial and Industrial RO Water Treatment Equipment Decade Long Trends, Analysis and Forecast 2025-2033,” published on September 5, 2025.