Innovative Advances in Industrial and Commercial Water Treatment Systems

Water treatment technology stands at the forefront of modern industrial and commercial operations. Especially when dealing with the complex chemical composition of seawater, robust and adaptive treatment systems are essential to meet demanding quality standards and diverse application needs. This article delves into core technologies and a broad spectrum of equipment options designed for various scales of water treatment, highlighting how these systems optimize performance, ensure reliability, and enhance operational efficiency.

Core Technology Modules in Water Treatment Systems

1. Reverse Osmosis (RO) Membrane Systems

RO represents the cornerstone of modern seawater treatment, capable of removing over 99% of dissolved salts, organic matter, and contaminants. Industrial RO plants typically incorporate multi-stage membranes, operating at high pressures (up to 60 bar) to achieve desalination in large-scale setups, whereas commercial units are tailored for lower feed volumes, often in the range of 0.5 to 10 cubic meters per hour.

- Technical Specs: High rejection rates (>98% for NaCl), operating pH range 3-11, recoveries up to 50-75% depending on feed water quality

- Scale Examples: Small systems for light commercial use (<1 m³/h), medium industrial plants (10-100 m³/h), and large municipal or industrial installations (>500 m³/h)

- Applications: Desalination for manufacturing processes, boiler feed water, beverage industry, and beyond

In industrial projects I managed, upgrading RO membranes to high-flux variants led to a 15% increase in throughput while reducing energy consumption, significantly improving the water cost profile.

2. Filtration and Softening Systems

Pre-treatment units including multimedia filters, activated carbon beds, and ion-exchange softeners are critical to removing suspended solids, chlorine, and hardness ions—protecting downstream membranes and ensuring system longevity.

- Technical Parameters: Backwash cycles configurable, removal efficiency for turbidity >99%, hardness reduction down to <1 ppm CaCO3

- System Capacities: Modular units scalable from 0.5 m³/h up to several hundred m³/h

- Performance Advantages: Mitigates membrane fouling and scaling, lowers corrosion risk, improving overall operational stability

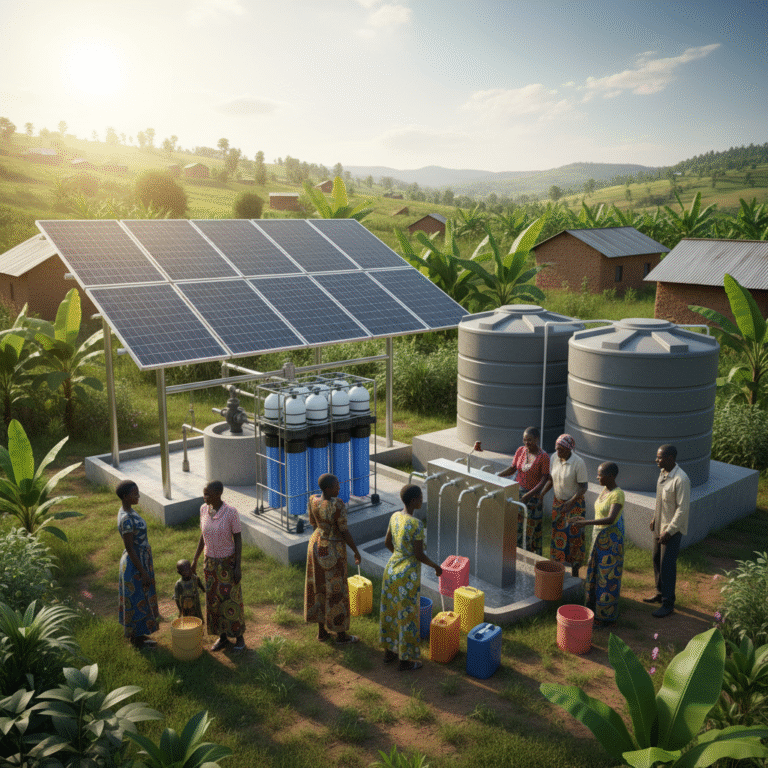

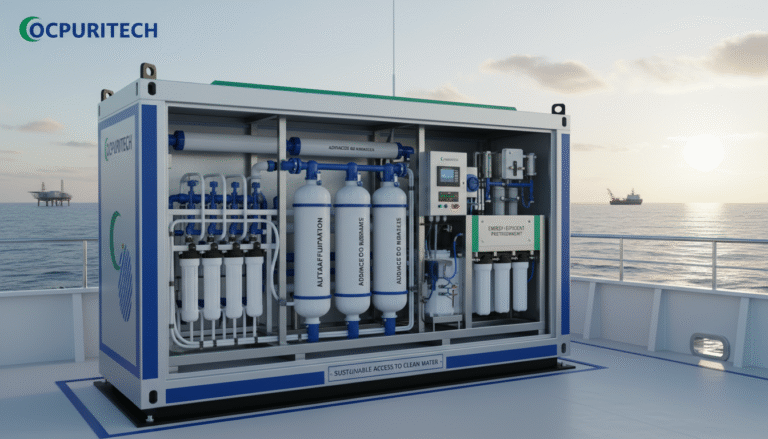

3. Containerized and Modular Systems

For ease of deployment, containerized water treatment plants package complex treatment trains (filtration, RO, and post-treatment) into mobile or compact units. These solutions serve remote industrial sites, disaster relief, or even space mission potable water preparation.

- Features: Plug-and-play operation, remote monitoring, wide capacity range from 5 to 100 m³/day

- Use Cases: Offshore platforms, mining camps, emergency supply, portable desalination

On a recent offshore contract, deploying containerized units helped reduce installation time by 40%, enabling quicker production ramp-up while ensuring water quality met strict marine equipment standards.

4. Cleaning and Disinfection Systems

Maintaining microbiological control is addressed by integrated cleaning in place (CIP) protocols and sterilization modules, such as ultraviolet (UV) disinfection and chemical dosing. These prevent biofouling and ensure hygienic water suitable for sensitive industrial processes and potable applications.

- Technical Insights: UV intensity adjustable up to 40 mJ/cm2, capable of 99.99% microbial inactivation

- Industrial Relevance: Critical for food and beverage plants, pharmaceutical manufacturing, and municipal water reuse

Manufacturers’ Expertise and Quality Assurance

Leading water treatment equipment manufacturers bring decades of specialized knowledge, combining fluid dynamics, materials engineering, and automation technologies. Their innovation pipelines continuously integrate corrosion-resistant alloys, advanced membrane chemistries, and intelligent control software, ensuring that equipment handles complex seawater matrices—rich in chloride, magnesium, calcium, and other ions—with superior durability and precision.

In my experience collaborating with these manufacturers, their rigorous quality control processes and after-sales service frameworks were pivotal in minimizing downtime and optimizing lifecycle costs for industrial plants, especially those processing high salinity seawater.

Industrial and Commercial Applications: Diverse and Expanding

Understanding the chemical composition of seawater—notably its 3.5% dissolved salts, chiefly sodium chloride, magnesium chloride, and calcium chloride—guides technology selection and system design. Applications stretch far beyond simple desalination:

- Seawater Desalination: Supplying fresh water for manufacturing, cooling towers, and irrigation

- Portable Drinking Water: Treatment systems for remote work sites, recreational vessels, and emergency response

- Special Environments: Providing reliable hydration for astronauts and remote scientific field stations through compact, efficient water processors

An illustrative case was a mining operation where we deployed a hybrid RO and filtration system combined with alkaline dosing to adjust pH, counteracting the aggressive corrosivity of native seawater—resulting in a 60% reduction in pipeline maintenance costs over two years.

Conclusion

The evolving landscape of water treatment technology underscores the importance of tailored solutions that address the intricate challenges posed by the chemical composition of seawater. By leveraging multi-tiered systems—ranging from state-of-the-art RO membranes to containerized, modular units—industries can ensure consistent water quality, operational resilience, and cost efficiency.

For professionals in industrial and commercial water treatment sectors, staying abreast of these technologies and manufacturer innovations is vital to designing future-proof, environmentally compliant, and economically viable water solutions.

References

- International Journal of Pure and Applied Sciences (CJPAS) – “Effect of chemical components on the tensile stress of embedded mild steel in freshwater, seawater and sea sand”

- NIOZ (Royal Netherlands Institute for Sea Research) – AQUA expedition insights on seawater chemistry