Advanced Industrial Water Treatment Equipment Manufacturing and Application: A B2B Technical Overview

As global industrial activities expand, the importance of reliable, high-performance water treatment systems becomes increasingly critical. Addressing the diverse purification needs across sectors such as manufacturing, pharmaceuticals, food & beverage, and municipal water supply requires technologically advanced equipment. This article presents an in-depth exploration of industrial water treatment equipment manufacturing, with a focus on product portfolios, technological innovations, market dynamics, and sustainable practices tailored for technical procurement professionals operating primarily in Africa, Southeast Asia, South America, and broader Asia.

1. Industry and Company Expertise in Industrial Water Treatment Equipment Manufacturing

The industrial water treatment sector demands specialized knowledge in both water chemistry and mechanical engineering. Manufacturers in this industry typically emphasize the following core principles:

- Technical Excellence: Expertise in developing high-precision purification systems, capable of handling complex feedwater profiles with varying contamination levels.

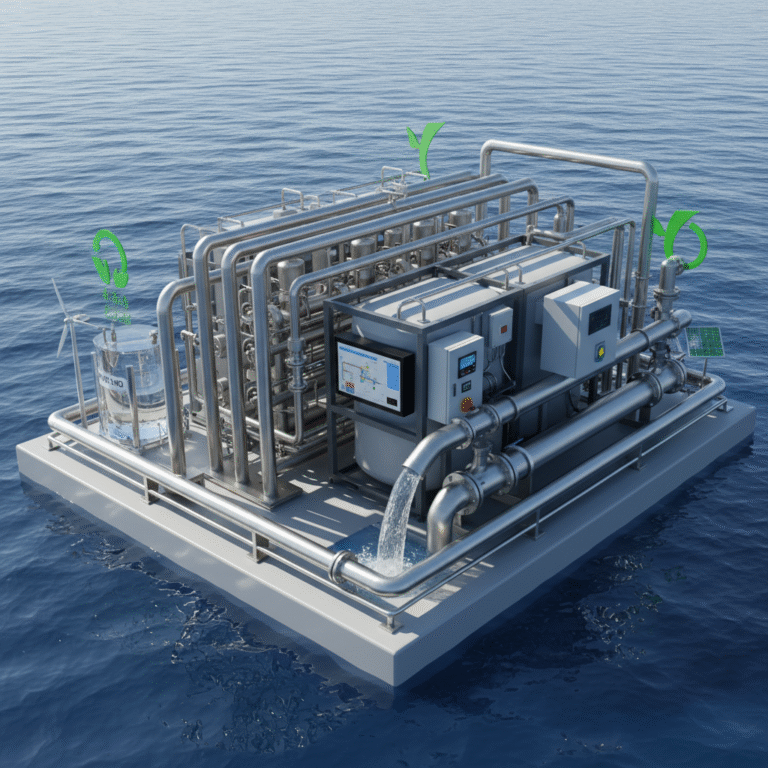

- Environmental Responsibility: Commitment to reducing water waste, minimizing chemical use, and facilitating water reuse in industrial processes to align with global sustainability goals.

- Innovative R&D: Continuous investments in research and development to pioneer next-generation membranes, energy-efficient pumps, and smart control systems that automate treatment processes.

Industrial water treatment plays a pivotal role not only in ensuring compliance with stringent discharge standards but also in protecting local ecosystems. Water is a critical resource in manufacturing processes, and advanced treatment equipment reduces operational risks and optimizes resource usage.

2. Comprehensive Product Portfolio of Industrial Water Treatment Equipment

A typical product lineup designed to meet the full spectrum of industrial water treatment needs includes:

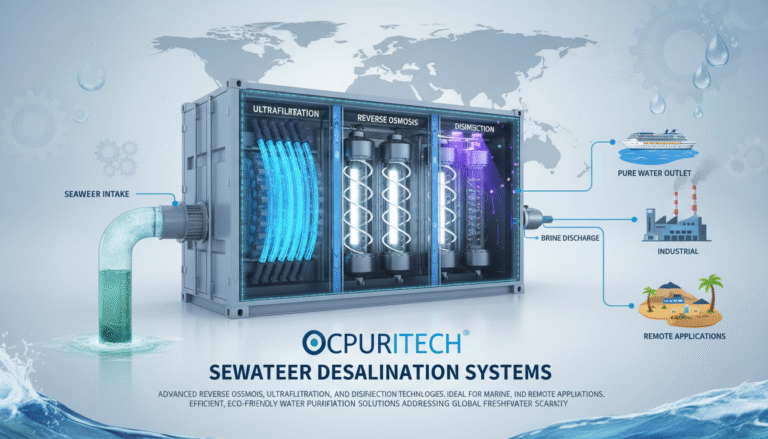

2.1 Reverse Osmosis (RO) Systems

Technical Parameters: High rejection membranes (>95%), operating pressures of 150-600 psi, recoveries of 75-85%, modular design for scalability.

Performance Advantages: RO systems remove up to 99% of dissolved salts, organic compounds, bacteria, and viruses. They provide high-purity water suitable for process, boiler feed, and potable use.

Typical Industries: Microelectronics manufacturing, pharmaceutical formulation, beverage production, and power plants.

2.2 Ultrafiltration (UF) Systems

Technical Parameters: Membrane pore sizes between 0.01-0.1 microns, operation at low pressures (20-100 psi), high flux rates.

Performance Advantages: Efficient removal of suspended solids, colloids, and macromolecules without the need for chemical pre-treatment. UF protects downstream processes by reducing turbidity and biological contaminants.

Typical Industries: Food & beverage, wastewater pre-treatment, medical and laboratory water purification.

2.3 Electro-Deionization (EDI) Systems

Technical Parameters: Continuous conductivity reduction to ultra-pure levels (<0.1 µS/cm), low chemical consumption, modular stack design.

Performance Advantages: Provides high-quality deionized water without the use of chemical regenerants typically required in ion exchange resins, resulting in lower operational costs and environmental impact.

Typical Industries: Semiconductor fabrication, pharmaceutical manufacturing, and chemical synthesis.

2.4 Pre-treatment and Softening Systems

Technical Parameters: Use of multimedia filters, activated carbon, water softeners employing ion exchange resins.

Performance Advantages: Protect downstream membranes and equipment by removing suspended solids, chlorine, hardness ions (Ca²⁺, Mg²⁺), and organic matter.

Typical Industries: General industrial facilities, municipal water plants, and power generation.

3. Innovation and Competitive Advantages

Technological advancement drives competitiveness in the industrial water treatment equipment industry. Innovations focus on membrane technology, energy efficiency, and automation.

| Technology Aspect | Traditional Systems | Advanced Systems | Benefits |

|---|---|---|---|

| Membrane Material | Standard RO membranes with lifespan ~2 years | Thin-film composite membranes with antifouling coatings | Extended membrane life, reduced fouling, improved flux |

| Energy Consumption | Conventional high-pressure pumps consuming >2 kWh/m³ | High-efficiency pumps and energy recovery devices | Up to 30% energy savings, lower operational costs |

| Automation & Control | Manual operation and monitoring | Integrated SCADA with remote monitoring | Real-time diagnostics, predictive maintenance |

Based on my professional experience working with industrial clients in Southeast Asia, integrating variable frequency drive (VFD) pumps in the RO system significantly lowered electricity consumption by 25%, enhancing ROI within the first 18 months. Similarly, a collaborative project in South America employing smart automation reduced membrane fouling downtime by 40%, leading to operational continuity and cost reductions.

4. Industry Positioning and Market Outlook

The global industrial water treatment market is projected to grow robustly due to accelerating urbanization, industrial expansion, and regulatory pressures. In particular, the under sink reverse osmosis water filter system segment accounts for a significant share in localized applications, comprising around 40% of user preference among RO systems. Residential and industrial markets witness increasing adoption of RO technology for its superior contaminant removal efficiency, with the global RO system market expected to reach approximately $11.9 billion by 2030 at a CAGR of 5.1% (Research and Markets).

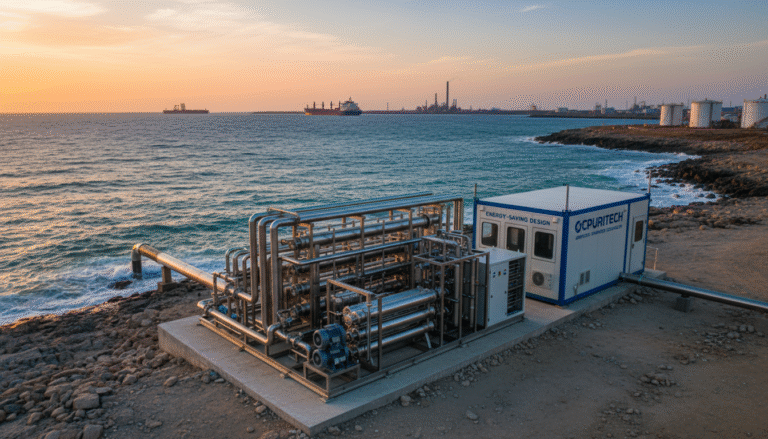

Regions including Africa, Southeast Asia, and South America demonstrate increased demand driven by urgent needs for clean water, industrial process optimization, and compliance with tighter discharge norms. Our manufacturing collaborations focus on addressing these regional challenges by delivering modular, scalable systems suitable for diverse feedwater qualities.

5. Manufacturing Capabilities and R&D Strength

Modern industrial water treatment equipment manufacturing relies on state-of-the-art production facilities that incorporate:

- ISO-certified quality management systems ensuring consistency and durability

- Advanced membrane fabrication and testing laboratories for rigorous performance validation

- Robotic assembly lines for precision component integration

- Experienced multidisciplinary R&D teams focusing on membrane chemistry, materials science, and process engineering

In various projects tailored to Southeast Asian industrial clusters, our R&D teams introduced membrane fouling predictors, enabling real-time system adjustments that enhance uptime and reduce maintenance frequency. Manufacturing process innovations include green fabrication methods reducing solvent usage, aligning with environmentally responsible practices.

6. Customer Case Studies and Proven Solutions

Case Study 1: Optimizing Water Purification in a Food Processing Plant – Southeast Asia

The plant needed reliable removal of microbial and chemical contaminants for bottling line water. Implementation of a combined ultrafiltration and reverse osmosis package decreased Total Dissolved Solids (TDS) from 750 mg/L to less than 50 mg/L, resulting in a 30% reduction in product spoilage incidents and compliance with international safety standards.

Case Study 2: Industrial Effluent Treatment – South America

A mining operation implemented advanced RO and EDI systems to treat contaminated wastewater for reuse. The solution achieved a 70% reduction in water consumption, translating into significant cost savings and reduced environmental footprint. Autonomous monitoring systems alerted operators to membrane fouling early, avoiding costly shutdowns.

Case Study 3: Power Plant Boiler Feedwater Preparation – Africa

Deploying a multi-stage water softening and reverse osmosis system secured ultra-pure water supply, increasing boiler lifespan and enhancing energy conversion efficiency. Maintenance intervals extended from 3 months to 9 months, generating operational cost savings estimated at 20% annually.

7. Commitment to Environmental Sustainability

Our equipment design philosophy integrates environmental stewardship through:

- Energy-efficient components reducing carbon footprints

- Minimization of chemical use via advanced membrane technology and process optimization

- Promotion of water reuse and zero liquid discharge (ZLD) options

- Adherence to global eco-certifications and green manufacturing standards

For example, in a recent project serving an industrial park in Asia, introduction of energy recovery devices in RO skids cut energy consumption by 28%, reducing greenhouse gas emissions significantly.

8. Contact and Customization Opportunities

For industrial clients seeking tailored solutions, our technical sales team offers comprehensive consultation services to design systems meeting precise feedwater conditions, production capacity, and ecological requirements.

- Email: [email protected]

- Phone: +1-800-555-1234

- Website Contact Form: Request a Quote

Our engineers collaborate closely with clients to perform site assessments, pilot testing, and flow schematics to ensure solutions deliver optimal performance and cost efficiency.

Summary

The industrial water treatment equipment manufacturing landscape is evolving rapidly, driven by technological breakthroughs and sustainability imperatives. Sophisticated systems such as under sink reverse osmosis water filter systems, advanced ultrafiltration, and electro-deionization units offer compelling operational advantages. Market growth in emerging economies underlines the critical role of robust, efficient water treatment solutions in supporting industrial development while safeguarding environmental resources. Combining authoritative market data and field-proven experience enables procurement teams to make informed investment decisions, ensuring peak system performance and long-term value.

References:

- Research and Markets – Reverse Osmosis (RO) Systems – Global Strategic Business Report – 2024

- Research and Markets – Reverse Osmosis (RO) Membrane Global Market Report 2025

- Grand View Research – Point Of Use Water Treatment Systems Market Worth $54.5 Billion By 2030

- Verified Market Research – Global Reverse Osmosis RO Membrane Market Size, Share, and Trends Analysis Report – 2024