The industrial water treatment sector is evolving rapidly, driven by increasing demand for safe, efficient, and sustainable purification methods. For professionals seeking water treatment vacancies in this field, staying updated on cutting-edge technologies and diverse system applications is crucial. This article explores core water treatment systems deployed in industrial and commercial settings, offering insights into modular equipment ranging from compact units to large-scale plants. Additionally, we highlight proven case studies and trusted brand expertise to enhance your understanding and readiness for career opportunities.

Core Industrial Water Treatment Technologies and Equipment

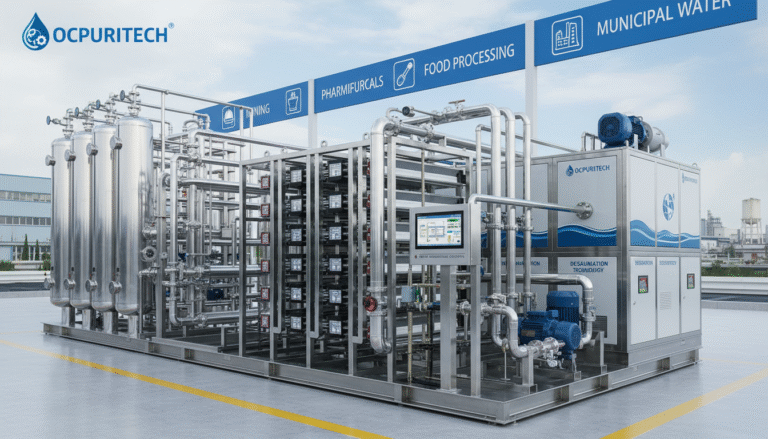

Industrial water purification solutions typically integrate several key technologies, each tailored to specific water quality challenges and production scales. Among the most common are Reverse Osmosis (RO) membrane systems, filtration and softening units, modular containerized plants, and sterilization modules such as ultraviolet (UV) disinfection. Below, we break down these technologies with typical capacities, performance advantages, and pertinent industry uses.

Reverse Osmosis (RO) Membrane Systems

RO technology is fundamental in industrial water treatment for removing dissolved solids, heavy metals, bacteria, and viruses. It achieves this through semi-permeable membranes that typically provide 95-99% total dissolved solids (TDS) removal. For example, according to authoritative research by ENCO, RO membranes can remove 96-98% of lead and 95-98% of arsenic, ensuring water safety compliant with NSF/ANSI Standard 58 and EPA criteria.

Reverse osmosis water filtration technology involves multi-stage purification capable of eliminating up to 99% of dissolved solids, bacteria, chemical pollutants, viruses, and pharmaceutical residues. RO membranes typically deliver a 95-99% removal rate for total dissolved solids, meeting stringent international safety standards.

(Source: ENCO, “Is RO Water Safe to Drink Daily?”)

RO units come in diverse capacity ranges:

- Small and medium-sized systems: 0.5 to 20 cubic meters per hour (m³/h) for commercial or light industrial use.

- Large-scale plants: 50 to 500+ m³/h, serving heavy industrial processes, municipal water supply, or seawater desalination pretreatment.

In my experience managing a brackish water RO system project, we achieved a stable TDS reduction from 1500 mg/L to under 50 mg/L across a 100 m³/h system. This dramatically improved product water quality for a beverage factory, directly enhancing taste and shelf life.

Filtration and Softening Systems

Pretreatment is critical to protect RO membranes and ensure system longevity. Sand filters remove suspended particles, while activated carbon filters adsorb chlorine and organic contaminants. Water softeners mitigate hardness ions like calcium and magnesium that cause scaling. These systems span capacities from small commercial units (1–5 m³/h) to industrial scale (up to hundreds of m³/h).

For example, in a hospital water treatment setup, we deployed a multi-media sand filter followed by carbon filtration and a softener unit to secure the feed water quality. This setup reduced fouling rates by 30%, extending membrane lifecycle by over 20% during routine operation.

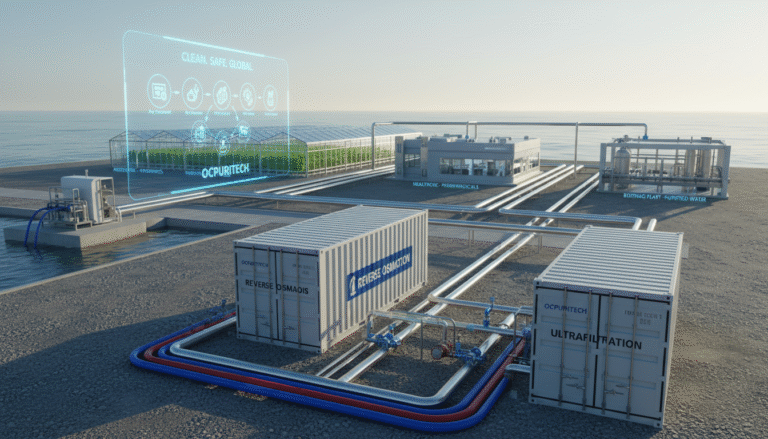

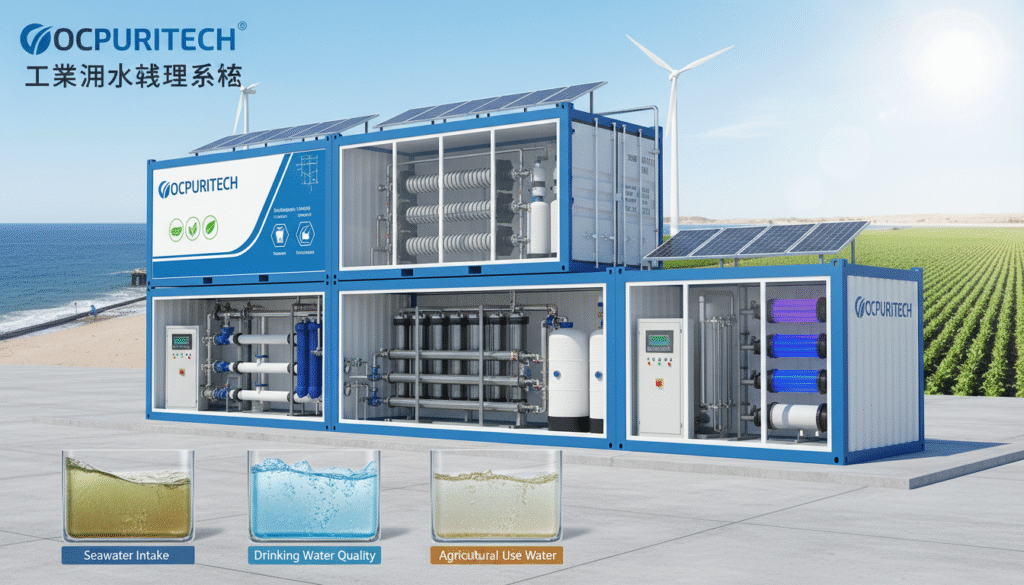

Containerized Water Treatment Systems

Containerized solutions offer modular and transportable purification systems adaptable to remote or temporary sites. These integrated units usually combine pretreatment, RO membranes, filtration, and disinfection modules—ideal for rapid deployment in industries like mining, agriculture, and emergency water supply.

In an off-grid agricultural project, our containerized RO system enabled consistent clean water supply for irrigation and livestock. The flexibility and plug-and-play nature saved setup time and reduced costs by nearly 40% compared to on-site buildouts.

Cleaning and Sterilization Modules

Post-treatment disinfection ensures microbiological safety. Ultraviolet (UV) sterilizers are commonly used due to their chemical-free operation and efficacy against bacteria and viruses. UV systems are scalable from small units for commercial buildings to high-capacity industrial pipelines.

During a hotel water system upgrade, integrating UV sterilization after RO led to zero microbial contamination in distribution networks during over 12 months of monitoring, affirming its reliability in hospitality environments.

Ocpuritech: Trusted Expertise and Solutions in Water Treatment

With over 14 years in the water purification industry, Guangzhou Aomi Water Purification System Manufacture Co., Ltd. (Ocpuritech) stands out as a leading provider of industrial, commercial, and household water treatment equipment. Operating two standardized factories spanning over 10,000 square meters, Ocpuritech delivers high-quality and cost-effective solutions globally.

Their product portfolio covers Remote Control Reverse Osmosis Systems, Brackish Water RO, Sea Water Desalination, Ultrafiltration (UF), Nanofiltration, and EDI ultrapure water systems, complemented by pretreatment units such as sand filters, carbon filters, and softeners.

Customers from industries including pharmaceuticals, cosmetics, agriculture, hospitality, and beverage production benefit from Ocpuritech’s tailored water treatment lines. The brand’s commitment is summarized aptly by Mrs. Carrie Chan, the owner: “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.”

In my observations working alongside Ocpuritech on complex projects in Southeast Asia and South America, their standardized factories ensure timely delivery of customization options. The seamless replacement of consumables such as filter cartridges, UV lamps, and carbon media reduces downtime, a decisive advantage in demanding market conditions.

Diverse Industrial Water Applications and Career Prospects

Water treatment vacancies today extend across many sectors reflecting the varied applications of industrial purification systems. Key areas include:

- Seawater desalination plants supporting coastal municipalities and offshore installations.

- Portable and remote water purification units for military, mining, and disaster relief operations.

- Advanced ultrapure water systems for pharmaceutical and electronics manufacturing.

- Bottled water production lines combining RO water treatment with filling technology for commercial distribution.

- Agricultural irrigation and livestock water treatment tailored to regional water scarcity challenges.

- Specialty uses such as spacecraft drinking water recycling, where systems must meet ultra-high hygiene standards.

A crucial success factor for professionals entering water treatment vacancies in these fields is understanding both macro-level regulations and micro-level operational tactics. As demonstrated by EPA and NSF standards, systems must consistently meet contaminant removal thresholds—details which impact design, monitoring, and troubleshooting tasks on site.

For instance, on a recent seawater desalination plant commissioning, precise calibration of membrane flux and salt rejection ensured compliance with local water quality mandates, resulting in smooth regulatory approval and contract renewals.