Marveling at Water Pretreatment System: Game-Changer for Industry?

In today’s industries, the quality and reliability of water used in processes are vital for operational efficiency, product quality, and regulatory compliance. The water pretreatment system emerges as a cornerstone technology addressing these demanding requirements. From mining and food processing to pharmaceuticals and municipal applications, pretreatment systems prepare raw water by removing contaminants that could impair downstream processes or damage sensitive equipment.

1. Product Overview: Types, Functions, and Industrial Applications

Water pretreatment systems generally function as upstream purification units that condition raw water by removing suspended solids, organics, and certain dissolved substances before final purification or direct industrial use. These systems encompass multiple technologies tailored to specific source water types, including river water, groundwater, municipal supply, well water, and even seawater.

Common types of pretreatment include:

- Coarse and fine filtration: Removal of heavy particulates and turbidity often through media filters and sedimentation tanks.

- Activated carbon filtration: Eliminates organic compounds, chlorine, and some micropollutants.

- Membrane-based filtration (microfiltration, ultrafiltration): Targets suspended solids, bacteria, and virus-sized particles.

- Chemical dosing systems: Adjust pH, add coagulants or anti-scalants to optimize downstream treatments.

Industries widely implementing pretreatment include:

- Mining: To protect boilers, evaporators and reduce scale in mineral processing circuits.

- Food and beverage: Ensuring water purity for hygiene, taste, and adherence to food safety regulations.

- Pharmaceuticals and cosmetics: Guaranteeing ultrapure water devoid of microbiological and chemical contaminants.

- Municipal and laboratory: Conditioning source water tailored for drinking water facilities or analytical applications.

- Boiler feed water treatment: Critical for reducing scaling and corrosion in steam generation systems.

In my decade-long experience managing water projects across Asia, I have observed that customizing pretreatment configurations according to raw water complexities—such as high turbidity in river water or organic load in well water—drastically improves the longevity and efficiency of subsequent purification steps.

2. Technical Principles and Key Components

A well-designed water pretreatment system blends mechanical, chemical, and membrane-based methods integrated with advanced controls to stabilize feedwater quality.

Membrane Filtration Technologies: Ultrafiltration (UF) and microfiltration (MF) membranes serve as vital barriers against colloids, bacteria, and suspended solids before Reverse Osmosis (RO) or other fine purification. UF membranes with pore sizes around 0.01 microns ensure consistent removal of pathogens and reduce fouling load on RO membranes, enhancing system longevity.

Automation and Control: Modern pretreatment units incorporate intelligent control systems utilizing pH sensors, turbidity meters, and flow controllers to adjust chemical dosing and backwash cycles. This minimizes manual intervention, maintains operational stability, and reduces downtime.

Precipitation and Adsorption Modules: Chemical coagulation and activated carbon filters remove dissolved organics and trace metals. Combined with sedimentation tanks, they significantly reduce suspended solids and color.

In a recent project serving a pharmaceutical plant, integrating ultrafiltration as a pretreatment step improved RO system uptime by over 30%, reducing cleaning frequency and operational cost. Automated monitoring enabled real-time adjustment of dosing chemicals, preventing over- or under-treatment.

3. Pricing Analysis: Cost Composition and Value

Acquiring a water pretreatment system requires understanding the breakdown of initial CapEx and ongoing OpEx to optimize investment.

| Cost Component | Description | Typical Relative Cost |

|---|---|---|

| Core Treatment Unit | Filters, membranes, chemical dosing equipment | 50%-60% |

| Automation & Control Systems | Sensors, PLC, HMI for process monitoring and control | 10%-15% |

| Installation & Civil Works | Infrastructure, piping, foundation, labor | 15%-20% |

| Operation & Maintenance | Membrane replacements, consumables, energy | 15%-20% annually |

Evaluating long-term benefits is essential. For instance, although membrane modules may involve significant upfront cost, their ability to reduce chemical consumption and increase water recovery translates into operational savings and environmental compliance benefits.

During my consultation for a food processing facility, an investment in high-efficiency membranes and automated controls resulted in a 25% reduction in energy consumption and a 40% decrease in maintenance downtime, yielding a payback period of under three years.

4. Performance Specifications and Quality Assurance

The performance of a water pretreatment system is assessed through parameters including:

- Turbidity reduction down to below 1 NTU

- Removal rates of Total Suspended Solids (TSS) > 95%

- Bacterial and microbial removal efficiency exceeding 99%

- Stable operation under flow variability and feedwater quality swings

Materials such as high-grade PVC, stainless steel 304/316, and FDA-approved membranes ensure corrosion resistance and compliance with hygienic standards.

Quality control protocols include factory acceptance testing (FAT), membrane integrity checks, and onsite commissioning validation. This rigorous approach guarantees durability and system reliability.

In a coal mine water treatment project I led, selecting industrial-grade stainless steel and implementing real-time monitoring prevented corrosion-induced failures, maintaining consistent feedwater quality for high-pressure boilers for over two years.

5. Market and Application Scenario Analysis

According to recent market analyses, the global water purification equipment market is projected to grow from $41.8 billion in 2025 to $80.8 billion by 2034, at a CAGR of 7.6%. Industrial water treatment represents a significant segment due to stricter regulations on microcontaminant removal, such as PFAS and pharmaceutical residues.

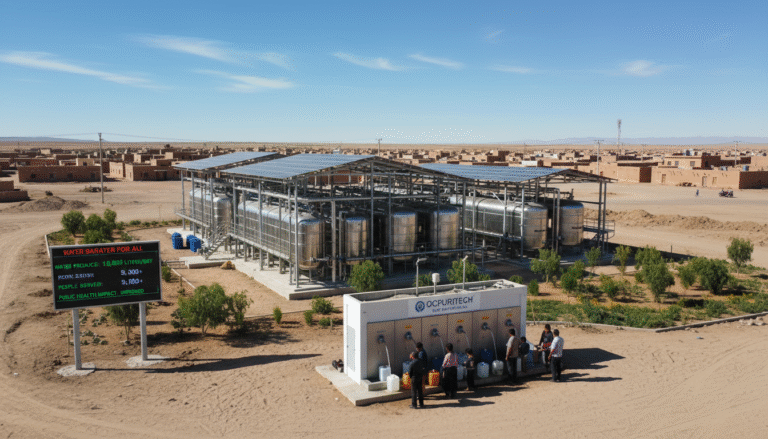

Regions with scarce fresh water sources and high industrial activity drive demand for advanced pretreatment for water reuse. Emerging smart water technologies leveraging IoT enhance efficiency and predictive maintenance.

In markets like the US and China, government infrastructure investments fund upgrades to drinking water and industrial treatment facilities, pushing adoption of membrane-based pretreatment and activated carbon filtration systems.

Industries with precise water quality demands (semiconductor, biotech) benefit extraordinarily from robust pretreatment to achieve ultra-pure water standards critical for product efficacy.

6. Case Studies: Real-World Application Insights

Case 1: Pharmaceutical Manufacturing Plant

Implemented a hybrid pretreatment system combining ultrafiltration and activated carbon filters before RO membranes. The system achieved:

- 99.9% microbial removal

- Reduced RO fouling rate by 35%

- Extended membrane life by 18 months

This translated to lower water downtime and ensured compliance with stringent USP water standards.

Case 2: Mining Operation Boiler Feedwater

Deployed pre-filtration and chemical dosing to eliminate scaling ions and turbidity. Benefits included:

- 15% fuel savings via improved boiler efficiency

- Reduction of unscheduled maintenance by 40%

- Water recovery rate improvement by 20%

Case 3: Food Processing Facility

Installed membrane pretreatment with automated control systems, achieving:

- Consistent flavor and quality in final product

- Energy use cut by 25%

- Reduced chemical usage by 30%

These cases reflect how tailoring pretreatment solutions to specific industrial needs maximizes operational gains.

7. Customization and Service Support

Effective water pretreatment system deployment involves tailored designs addressing source water characteristics and product water quality targets.

Pre-treatment customization options include parameter-specific chemical dosing, modular filter assemblies, and scalable membrane arrays. Post-treatment integration—such as UV disinfection or ion exchange—further ensures water purity.

Manufacturers typically provide end-to-end services:

- Site survey and water quality analysis

- System design and engineering

- Installation and commissioning with validation

- Scheduled maintenance contracts and remote monitoring support

My experience shows that investing in comprehensive service agreements reduces downtime risk and enhances system lifecycle value.

8. Manufacturer Profiles and Collaborative Advantages

Leading producers of water pretreatment systems emphasize quality certifications like ISO 9001 and NSF approval, and offer broad references across challenging industrial sectors globally.

Their core competencies include R&D investment in membrane innovation, integration of smart control platforms, and commitment to sustainability through energy-efficient designs.

Partnership with reputable manufacturers ensures access to cutting-edge technology, rapid technical support, and continuous product upgrades, crucial for maintaining competitiveness in industrial water management.

9. Comprehensive Conclusion and Investment Recommendations

Water pretreatment systems are unequivocally pivotal in advancing industrial water management. Their ability to protect downstream purification, lower operational costs, and ensure product quality represents a game-changing advantage.

From market trends to personal project outcomes, embracing advanced pretreatment—particularly membrane-integrated, automated solutions—provides industries with resilience against water quality fluctuations and regulatory pressures.

Investment strategies should prioritize:

- Aligning pretreatment complexity with feedwater variability and water quality requirements

- Focusing on Total Cost of Ownership (TCO), including maintenance and energy use

- Leveraging digital monitoring for proactive maintenance and process optimization

- Selecting manufacturers with proven expertise and comprehensive service packages

By integrating these insights, businesses can capitalize on the growing demand for sustainable and efficient water treatment solutions, ultimately enhancing operational excellence and environmental stewardship.

References:

- According to USD Analytics’ research (2025), the global water purification equipment market is forecasted to nearly double by 2034, driven by industrial and municipal demand.

- Precedence Research (2025) highlights the rising importance of mixed water treatment technologies and IoT-enabled smart purification systems in industrial sectors.

- Real Time Data Stats reports emphasize industrial water treatment as the largest market segment in 2024, reflecting strict process water quality regulations.