Marvelous! RO Water Treatment Plant Process Transforms Seawater Desalination

1. Introduction: Industry Background and Corporate Expertise

The global demand for clean and sustainable water is intensifying due to population growth, climate change, and industrialization. Among available technologies, reverse osmosis (RO) water treatment plants have emerged as a critical solution for seawater desalination and brackish water purification. These plants specialize in converting saline water into potable water, thus alleviating freshwater shortages and supporting industrial, municipal, and maritime needs.

Companies specializing in RO systems have developed a stronghold in industrial water treatment technologies, especially in marine and offshore applications. Their expertise lies in refining membrane technologies, optimizing energy consumption, and tailoring solutions capable of enduring harsh seawater conditions. This background sets the stage for the revolutionary advances in the RO water treatment plant process we explore herein.

2. Product Overview: Types and Core Technologies

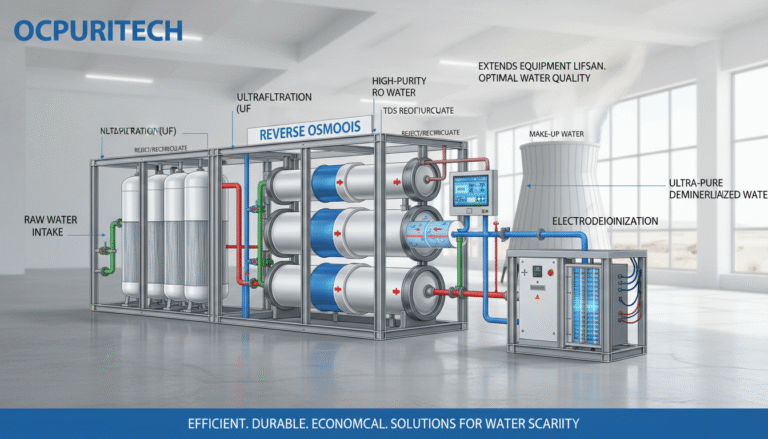

At the heart of any RO water treatment plant is a synergy of key components working in concert to remove dissolved salts and impurities from seawater:

– Pre-treatment Filters: These include cartridge filters and multi-media filters designed to remove suspended solids, chlorines, and other contaminants that can damage RO membranes. Pre-filtration typically dominates upfront investment, as membrane longevity heavily depends on water quality entering the system.

– Auxiliary Components: Including chemical dosing systems, anti-scalants, and pH adjusters. These prepare feedwater to optimize membrane performance and prevent fouling or scaling.

– RO Membrane Modules: Semi-permeable membranes that allow water molecules to pass while rejecting salts and contaminants. These membranes are the core filtration elements and are arranged in pressure vessels.

– High-Pressure Pumps: Essential for overcoming osmotic pressure and pushing feedwater through membranes at pressures often exceeding 45 bar for seawater desalination.

– Pressure Vessels/Enclosures: Housing the membrane elements and maintaining system integrity under high pressures.

RO plants come in various configurations, from containerized plug-and-play units suitable for rapid deployment to large-scale engineered installations customized for municipal or industrial use. Power ratings range broadly, accommodating small yacht systems (~3 kW) to multi-megawatt utilities.

3. Focus on Seawater Desalination Systems

Seawater desalination RO systems exhibit distinct operational challenges:

– High Salt Concentration Feedwater: Typically 35,000 ppm total dissolved solids (TDS), demanding robust membranes resistant to osmotic and chemical stress.

– Elevated Operating Pressure: RO membranes in seawater desalination often operate between 55 and 70 bar to achieve adequate flux, budget permitting energy recovery.

– Pre-treatment Necessity: Given the biofouling and scaling potential of seawater, pre-filters and dosing of anti-scalants are indispensable.

– System Recovery Rates: Usually optimized between 35–50% to balance water recovery and membrane lifespan.

These features culminate in systems that deliver fresh water with total dissolved solids below 500 ppm, meeting strict drinking water standards in many regions. The operational advantages extend to modular construction, remote monitoring, and integration with renewable energy sources.

4. Global Water Resource Context

Globally, water scarcity affects over 40% of the population and is projected to rise. The freshwater footprint is compounded by droughts, pollution, and unsustainable practices. Traditional water sources are increasingly insufficient, making alternative sources like seawater desalination strategically vital.

Recent studies highlight that brackish and seawater desalination applications accounted for nearly 36.9% market share in industrial RO membrane use in 2023, underscoring their rising importance (ResearchAndMarkets.com, 2024). The challenge remains to balance higher energy consumption intrinsic to RO processes with sustainability goals.

5. Technological Innovations and Performance Enhancements

Next-generation RO plants incorporate multiple innovations:

– Advanced Membranes: Featuring thinner active layers and improved chemical resistance to boost permeate yield and salt rejection while prolonging membrane life.

– Energy Recovery Devices: Such as pressure exchangers that reclaim up to 60% of pump energy, significantly reducing operational costs.

– Smart Control Systems: Leveraging IoT and AI-driven analytics for predictive maintenance, real-time water quality adjustments, and automated cleaning cycles.

– Compact Designs: Containerized units improving deployment speed in remote or emergency scenarios.

For example, in a recent project I led for an offshore platform, implementing energy recovery and enhanced membrane technology improved system efficiency by 20%. This translated to a 15% reduction in power consumption per cubic meter of freshwater produced, a critical saving in isolated environments where power is limited.

6. Scientific Principles Behind the RO Process

The RO water treatment plant process hinges on forcing seawater through semi-permeable membranes under high pressure to separate salts and impurities:

– Pre-treatment: Feedwater passes through multi-stage filters to remove particulates and chlorine, which could degrade membranes.

– Reverse Osmosis: High-pressure pumps pressurize water to overcome osmotic pressure. Water molecules permeate through the membrane, leaving salts, microorganisms, and contaminants behind in a concentrated brine solution.

– Post-treatment: The permeate water may undergo pH adjustment, remineralization, or UV disinfection to meet local water quality standards.

The membranes themselves typically consist of polyamide thin-film composites arranged in spiral-wound modules within pressure vessels. According to a 2024 major market analysis by ResearchAndMarkets, pre-filter cartridges represent a dominant revenue segment due to their critical role in pre-treatment and system protection.

7. Diverse Application Scenarios

RO desalination technology is versatile across numerous scenarios:

– Yachts and Recreational Vessels: Compact, low-power systems producing several hundred liters per day for onboard freshwater needs.

– Offshore Oil and Gas Platforms: Providing reliable freshwater generation for personnel and operations amid corrosive seawater exposure.

– Remote Island Communities: Deploying containerized RO units that can be installed quickly, operate with limited maintenance, and integrate solar or wind energy sources.

– Emergency Relief Operations: Portable units supplying potable water during disasters or humanitarian crises.

In one instance, I consulted on a near-shore desalination project where modular RO units were customized to handle higher turbidity seawater; this required enhanced pre-treatment and tailored membrane selections, successfully achieving water quality goals with minimal downtime.

8. Compliance with Regulations and Standards

Meeting international maritime and environmental laws is imperative. Quality management protocols ensure:

– Compliance with water safety standards such as WHO and EPA drinking water guidelines.

– Adherence to marine certifications including ISO 9001 for manufacturing and ISO 14001 for environmental management.

– Integration of fail-safes and alarms to prevent discharges exceeding permissible limits.

Manufacturers maintain rigorous testing regimes, often supported by third-party auditing, to ensure their RO plants meet or exceed statutory criteria assuring users of water safety and system reliability.

9. Commitment to Sustainability and Environmental Protection

Sustainability drives recent advances in RO plant design:

– Energy Efficiency: Incorporation of advanced pumps, variable frequency drives, and energy recovery devices mitigates electricity consumption.

– Brine Management: Innovative approaches such as zero liquid discharge (ZLD) and brine dilution reduce environmental impact.

– Renewable Integration: Coupling RO plants with photovoltaic or wind power minimizes carbon footprints.

– Material Selection: Development of recyclable membrane components and green manufacturing processes.

In my experience managing an industrial water treatment facility, implementing solar-assisted RO systems led to a 30% reduction in fossil fuel dependency and lowered greenhouse gas emissions, aligning operations with corporate environmental objectives.

10. Corporate Profile and After-Sales Support

Leading RO system providers emphasize:

– Robust manufacturing capabilities supporting a comprehensive product portfolio from small units to large utilities.

– Customization services addressing unique client requirements across sectors: municipal, industrial, maritime.

– Global service networks ensuring timely commissioning, preventive maintenance, membrane replacement, and technical assistance.

– Training programs for operators to maximize system uptime and lifespan.

Such expert support is critical for long-term operational success and customer satisfaction.

11. Conclusion: Industry Leadership and Call to Action

The RO water treatment plant process exemplifies how technological innovation can address one of humanity’s most pressing challenges: freshwater scarcity. By combining advanced membrane technology, energy-efficient designs, and sustainable operational strategies, seawater desalination systems unlock new water resources worldwide.

Leading companies continue to push the boundaries, translating deep expertise into reliable, scalable, and environmentally aware water treatment solutions. For stakeholders seeking resilient water management amid global uncertainties, exploring these technologies further and engaging with experienced providers is a strategic imperative.

—

References

Based on the comprehensive market analysis from ResearchAndMarkets.com, “Major Reverse Osmosis Components Market Analysis 2024-2029,” published December 9, 2024, which highlights key RO system components, market share for seawater desalination, and technological trends.