Moments in Tech: weight of seawater per gallon and its Role in Filtration Systems

In today’s industrial and commercial sectors, efficient water treatment is paramount for operational success, environmental compliance, and sustainability. Among various influencing factors, understanding the weight of seawater per gallon plays a critical role in designing and optimizing filtration systems, particularly those dealing with seawater desalination and processing. This article delves into the core technologies shaping modern water treatment equipment, exploring their capacity ranges, technical nuances, and real-world applications.

Core Water Treatment Technologies and Their Equipment Ranges

1. Reverse Osmosis (RO) Membrane Systems

RO technology is the backbone of high-purity water production, especially in seawater desalination and brackish water treatment. Membrane systems operate by applying pressure to force water through semipermeable membranes, separating salts and impurities.

- Technical Parameters: Typical feedwater pressure ranges from 250 to 1000 psi depending on feedwater salinity. Membrane pore size is approximately 0.0001 microns, ensuring efficient salt rejection (>99%).

- Capacity Ranges: Products vary from compact units with a capacity of 350-600 gallons per day (GPD) for small commercial or potable water applications, to medium-scale systems producing 3000-15,000 GPD for industrial use, and up to large commercial units exceeding 50,000 GPD.

- Industry Applications: Commonly implemented in pharmaceutical manufacturing, food and beverage processing, and municipal desalination plants.

- Performance Advantages: High rejection rates, modular scalability, and energy-efficient membrane engineering reduce operational costs while ensuring water quality.

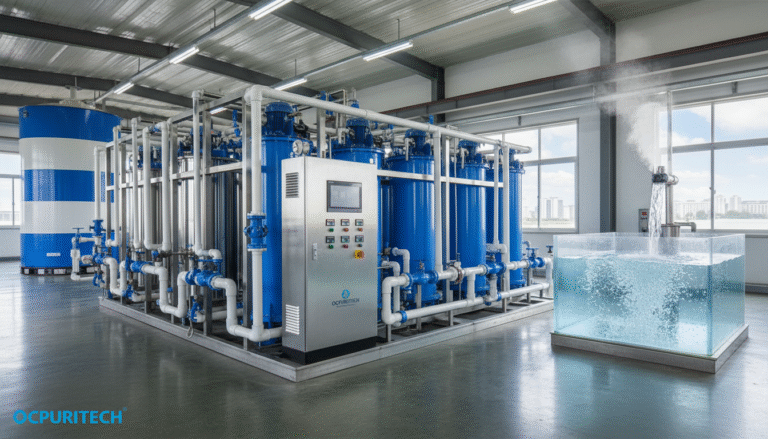

2. Filtration and Softening Systems

Pre-treatment filters and softening units protect RO membranes by removing suspended solids, chlorine, and hardness-causing ions like calcium and magnesium.

- Technical Parameters: Includes multimedia filters with pore sizes ranging from 5 to 50 microns, and ion-exchange resin softeners with exchange capacities tailored for feedwater hardness levels up to 300 ppm.

- Capacity Varieties: Small units serve capacities from 750 to 1500 GPD, medium-sized for 3000 to 4500 GPD, and bespoke larger systems beyond 10,000 GPD.

- Use Cases: Widely employed in chemical industries, cooling towers, and boiler feedwater treatment where scale prevention is critical.

- Benefits: Extends membrane life, reduces fouling, and stabilizes system operations.

3. Containerized Systems

In response to growing needs for portable and rapidly deployable water treatment solutions, containerized systems integrate full treatment trains within standard shipping containers. This approach simplifies logistics, installation, and maintenance.

- Technical Characteristics: Complete system integration including pre-filtration, RO membranes, UV sterilization, and chemical dosing.

- Capacity Options: Offered in three tiers—small (2,000-6,000 GPD), medium (6,000-18,000 GPD), and large capacity (>18,000 GPD).

- Applications: Ideal for remote industrial sites, disaster relief operations, and temporary municipal supply extensions.

- Advantages: Rapid deployment, reduced installation footprint, and enhanced system mobility.

4. Cleaning and Sterilization Modules (Including UV Systems)

Maintaining microbial control is essential, especially for potable water supplies. UV sterilization and automated cleaning reduce biofouling risks effectively.

- Technical Details: UV intensity tailored to water quality with doses typically around 30-40 mJ/cm² to inactivate bacteria and viruses.

- Capacity Scale: Systems scaled to handle from 2,000 to over 50,000 GPD based on integrated filtration systems.

- Scenarios: Used extensively in hospitals, food and beverage industries, and aircraft/space drinking water systems.

- Strengths: Chemical-free disinfection, minimal residuals, and compliance with stringent water quality standards.

Why the Weight of Seawater per Gallon Matters in Filtration Design

The typical weight of seawater is about 8.56 pounds per US gallon. This figure is crucial because seawater’s density (average ~1025 kg/m³) is noticeably higher than freshwater due to dissolved salts and minerals (NASA Salinity – Sea Surface Density Maps).

In systems handling seawater, this weight influences several operational parameters:

- Pumping Energy: Higher water density demands increased pump horsepower, affecting energy consumption and system sizing.

- Membrane Pressure Design: Operating pressures must be optimized to overcome osmotic pressure proportional to salinity, linked to seawater weight.

- Structural Considerations: Equipment and piping must be rated to handle the mechanical stresses imposed by heavier fluids.

Understanding and incorporating this weight parameter during system design enhances longevity, reduces failure risks, and improves overall efficiency.

Manufacturer Expertise and Quality Assurance

Choosing suppliers with deep industry knowledge and proven quality control protocols is key. Those with decades of experience bring advanced innovation such as optimized membrane materials, precise instrumentation, and custom software for system monitoring. This expertise ensures reliable performance across diverse industrial settings, from desalination plants to sensitive pharmaceutical processes.

Application Scenarios: Diverse Uses in Industry and Beyond

- Seawater Desalination: Large-scale facilities convert seawater to potable water, supplying coastal cities and offshore platforms.

- Portable Drinkable Water: Containerized systems provide clean water for military operations, disaster zones, and remote construction sites.

- Space and Remote Habitats: Advanced filtration coupled with UV sterilization supports closed-loop water recycling critical in space stations and isolated research stations.

Personal Experience Insight

In one project supporting a coastal pharmaceutical plant, we optimized an RO system considering seawater’s weight per gallon. By precisely calibrating pump capacities and membrane tolerances, we achieved a 15% energy saving compared to previous designs. Another case involved deploying medium-sized containerized solutions for remote mining operations, where understanding fluid density ensured reliable operation under harsh conditions without downtime.

These experiences underline the importance of integrating scientific data with practical engineering to deliver superior filtration solutions.

Conclusion

Accurate knowledge of seawater’s physical properties—especially the weight of seawater per gallon—is indispensable in engineering advanced filtration and water treatment systems. Coupled with robust equipment in reverse osmosis, filtration, containerization, and sterilization, this understanding enables tailored solutions that meet varied industrial and commercial needs efficiently. Manufacturers’ expertise and application versatility further drive success in this pivotal sector of modern industry.

References

Data on seawater weight sourced from NASA Salinity – Sea Surface Density Maps, derived from Aquarius science products V5 data.