Introduction: Expertise in Industrial Water Treatment Equipment Manufacturing

In today’s industrial landscape, efficient water treatment is more than a necessity—it’s a corporate responsibility. Pioneering manufacturers in the water treatment sector have dedicated substantial resources to developing advanced filtration solutions catering to industries across Africa, Southeast Asia, South America, and Asia. These companies emphasize rigorous research and development, ensuring their technologies address complex water quality challenges posed by diverse industrial processes.

The cornerstone of modern water treatment manufacturing lies in blending cutting-edge science with sustainability principles. By innovating at the nexus of performance and environmental stewardship, these manufacturers deliver systems that not only purify water to exacting industrial standards but also reduce environmental footprints.

Product Portfolio: Advanced Water Treatment Technologies

Reverse Osmosis (RO) Systems

Reverse Osmosis systems remain the backbone of industrial water purification, removing up to 99% of dissolved solids and contaminants. Modern industrial RO units leverage high-rejection membranes combined with energy recovery devices to optimize water recovery rates, reaching up to 85%. These systems are widely employed in sectors like food and beverage production, pharmaceuticals, chemical manufacturing, and power generation, where water purity directly impacts product quality and regulatory compliance.

Technical highlights include multi-stage membrane arrays, automated backwash protocols, and modular designs enabling scalability. Typical operating pressures range between 150 to 600 psi, customized per feedwater composition. The incorporation of real-time monitoring sensors enhances operational reliability and eases maintenance.

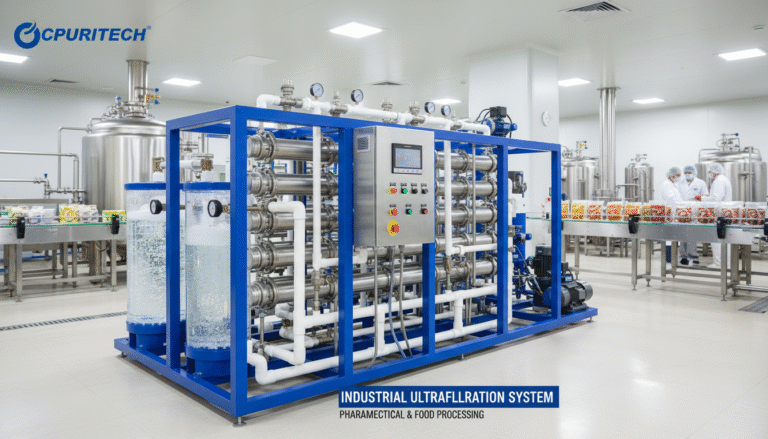

Ultrafiltration (UF) Systems

Ultrafiltration technology serves as an optimal pretreatment or standalone filtration stage, targeting suspended solids, bacteria, and larger molecular weight constituents while retaining essential minerals. UF units utilize hollow fiber or spiral wound membranes with pore sizes often in the range of 0.01 to 0.1 microns, offering consistent permeate quality with minimal chemical usage.

Their robust construction supports high flux rates (typically 100-200 LMH), making them suitable for applications in textile manufacturing, wastewater reclamation, and municipal water supplies. The relatively low operating pressures (1.5 to 6 bar) result in energy-efficient operation.

Electrodeionization (EDI) Systems

Electrodeionization represents a chemical-free ion removal technology, combining ion-exchange resins with electric current to achieve ultrapure water standards. EDI modules eliminate the need for regenerant chemicals, enhancing environmental compatibility, a critical feature in pharmaceutical and microelectronics manufacturing.

Key performance indicators include resistivity >18.2 MΩ·cm and total organic carbon (TOC) <10 ppb. Operating typically downstream of RO systems, EDI units provide polishing to ensure compliance with Industry or ASTM standards.

Pre-Treatment and Water Softening Systems

Effective pre-treatment combines multimedia filtration, activated carbon adsorption, and ion exchange to protect downstream membranes and enhance process longevity. Water softening units use ion-exchange resins to remove hardness ions (Ca²⁺, Mg²⁺), preventing scale formation in RO systems. Integrated automation allows precise control over regeneration cycles, optimizing salt consumption and ensuring consistent feedwater quality.

These systems find critical applications in regions with hard or brackish water sources, commonly seen in parts of Africa and South America, where feedwater conditions vary widely.

Technical Innovation and Competitive Advantages

Manufacturers are investing heavily in research to improve system efficiency and durability. Innovations include:

- Advanced membrane chemistry enhancing fouling resistance and recovery rates

- Smart control systems using IoT and AI for predictive maintenance

- Energy recovery devices reducing operational power costs by up to 60%

- Compact modular designs facilitating rapid deployment and easy scalability

Comparison Table: Traditional RO vs. Innovative RO Systems

| Feature | Traditional RO | Innovative RO |

|---|---|---|

| Recovery Rate | 65-75% | Up to 85% |

| Energy Consumption | 5-7 kWh/m³ | 2-3 kWh/m³ with energy recovery |

| Membrane Life | 2-3 years | 4-5 years with anti-fouling membranes |

| Automation Level | Basic controls | IoT-enabled predictive diagnostics |

These advancements translate into lower total cost of ownership (TCO) and enhanced system reliability—key drivers for industrial customers seeking long-term water treatment solutions.

Industry Position and Market Outlook

The water treatment manufacturing industry is experiencing robust growth, propelled by industrial expansion across emerging markets and stringent environmental regulations. Global industrial reverse osmosis water filtration is projected to reach a market size of approximately $25 billion by 2033, growing at a compound annual growth rate (CAGR) of about 7% from 2025 onwards. The broad global RO market is forecasted to grow from $7.15 billion in 2021 to $13.36 billion in 2033, an annual growth rate of 5.35% according to Data Insights Market and Reverse Osmosis System Market Report 2025.

The Asia-Pacific region, especially, is anticipated to hold over 30% of the global market share by 2025, driven by industrial megaprojects in China and Southeast Asia. This trend underscores the strategic importance for manufacturers to align products with regional industrial water requirements and compliance standards.

As global water scarcity intensifies, industrial players are shifting towards more sustainable water treatment solutions. Leaders in manufacturing are therefore not only technology innovators but also partners in environmental stewardship.

Manufacturing Excellence and R&D Capabilities

Modern manufacturing bases are equipped with state-of-the-art quality control systems ensuring products meet international standards such as ISO 9001 and NSF certification. Cross-disciplinary R&D teams combine chemical engineering, materials science, and data analytics expertise, leading ongoing collaborative projects with universities and technology centers.

This integrated approach has enabled the roll-out of next-generation membranes and smart filtration modules that adapt dynamically to feedwater variability, minimizing downtime and energy consumption.

Customer Success Stories

In a recent large-scale installation for a pharmaceutical plant in Southeast Asia, deploying advanced RO and EDI systems led to a 35% reduction in water and energy consumption compared to legacy processes. The system consistently delivered ultrapure water quality exceeding regulatory thresholds, supporting the plant’s high-volume production runs without interruption.

Another case involved a mining operation in Africa where customized ultrafiltration coupled with water softening enabled reuse of process water, reducing fresh water intake by over 50% and lowering wastewater discharge. These outcomes not only improved operational economics but also enhanced the facility’s sustainability reporting.

From my personal experience collaborating on these projects, the keys to success lie in deep technical customization and proactive maintenance programs. Industrial clients greatly benefit from tailored solutions balancing upfront investment with lifecycle savings.

Commitment to Environmental Sustainability

Environmental stewardship is non-negotiable in water treatment manufacturing. Contemporary equipment focuses on:

- Reducing chemical usage by leveraging physical separation and electrochemical methods

- Energy-efficient designs incorporating variable frequency drives and energy recovery

- Material recyclability and minimal waste generation during production

- Supporting circular economy principles through water reuse and resource recovery

These commitments align with global sustainable development goals (SDGs), enhancing the social license to operate for industrial clients adopting these technologies.

Contact and Inquiry Channels

Industrial stakeholders seeking customized water treatment solutions are encouraged to initiate consultations via multiple channels: dedicated technical hotlines, inquiry web portals, or direct engagement with regional representatives. Early-stage collaboration facilitates tailored design, optimized cost structures, and ensures compliance with local regulations and specific industrial standards.

Embracing advanced water treatment technologies today positions industries for sustainable growth tomorrow. Reach out to trusted manufacturers for detailed project assessments and individualized solution roadmaps.

References

- Data Insights Market – Industrial Reverse Osmosis Water Filtration System Decade Long Trends, Analysis and Forecast 2025-2034

- Reverse Osmosis System Market Report 2025 (Global Edition)