Effective management of industrial wastewater is critical for environmental protection and sustainable operations. Reliable sewage water treatment machinery offers a robust solution to reduce pollutants and ensure compliance with stringent regulations. In this article, we discuss the core technologies and versatile equipment lines designed to handle diverse industrial effluent challenges, highlighting key features, operational insights, and practical applications.

Advanced Reverse Osmosis (RO) Membrane Systems

Reverse Osmosis is a cornerstone technology in sewage water treatment machinery, capable of removing dissolved solids, heavy metals, and organic contaminants with high precision. Utilizing membranes made from materials such as polyamide and polysulfonate, modern RO systems provide superior selectivity and durability.

Our experience in deploying RO systems across various industries confirms that implementing advanced membranes with larger surface areas and optimized flow patterns significantly boosts treatment efficiency while trimming energy consumption. For instance, integrating spiral wound modules with diameters exceeding standard 8-inch membranes can reduce lifecycle costs markedly—critical for industrial users aiming to optimize capital expenditure and minimize downtime.

According to the Department of Energy (2024) Reverse Osmosis Optimization, such improvements elevate performance metrics and drive eco-friendly operation by cutting water and power utilization.

Additionally, pre-treatment stages involving sediment filters, water softeners, and pH adjusters are indispensable for minimizing membrane fouling and scaling, hence extending membrane longevity and reducing maintenance cycles. From direct experience operating brackish water and industrial wastewater projects, systems equipped with tailored pretreatments see a 30-40% increase in annual uptime.

Filtration, Softening, and Modular Containerized Systems

The backbone of any efficient sewage water treatment machine includes robust pretreatment modules. Sand filters and carbon filters serve to eliminate suspended solids, chlorine, and organic matter, significantly improving downstream RO membrane lifespan.

Notably, advanced chemical softening techniques offer scalable solutions for mitigating calcium and magnesium hardness, essential for maximizing RO recovery rates. Precise dosing systems calibrated to local water profiles have proven critical in preventing membrane damage, thereby controlling chemical costs and operational risks.

Flexible containerized water treatment units, equipped with integrated filtration, softening, and RO modules, provide plug-and-play adoption especially suitable for remote or space-constrained industrial sites. In one project aiming to treat saline industrial effluent on an offshore platform, our modular system achieved consistent conductivity reduction while maintaining compact footprint and ease of transport.

These scalable solutions include multiple capacity ranges—from compact 500 liters per hour units to large-scale 100,000 liters per hour systems—catering to diverse customer requirements across sectors such as pharmaceuticals, textiles, and food processing.

Cleaning, Disinfection, and Ultraviolet (UV) Sterilization

Water quality post-RO filtration benefits immensely from secondary treatment steps that target biological contaminants. Ultraviolet disinfection stands out as an eco-friendly, chemical-free method to effectively neutralize pathogens including viruses and bacteria.

Incorporation of UV sterilization systems within industrial sewage treatment machinery enhances microbial safety and ensures compliance with discharge standards. Studies show these systems can achieve microbial counts below 1 colony-forming unit per 100 ml, suitable for ultrapure water needs in industries like semiconductor and pharmaceuticals (NIH, 2023 UV technology application).

From operational experience in beverage and cosmetics plants, regular UV system maintenance and sensor monitoring are vital to ensure consistent germicidal performance and avoid costly biofilm buildup or system downtime.

- UV modules designed for continuous operation with easy sensor replacement protocols

- Automated cleaning cycles and fail-safe alarms to optimize disinfection consistency

- Integration with ozone treatment for synergistic pathogen removal in highly contaminated streams

These features collectively elevate effluent standards and contribute to environmental stewardship efforts increasingly demanded by regulators and eco-conscious industries.

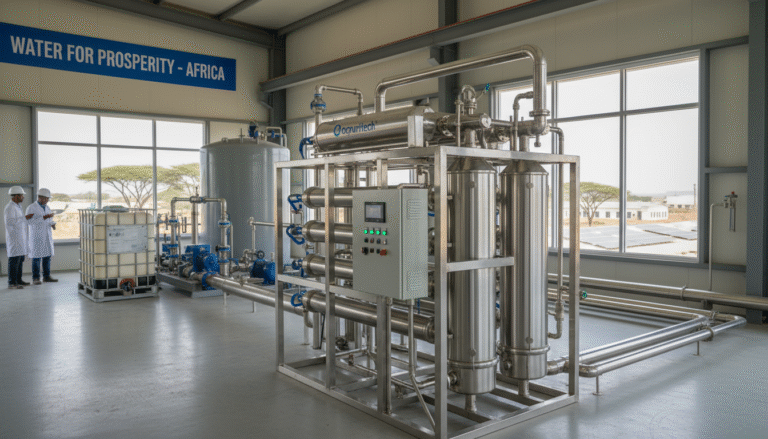

Ocpuritech’s Expertise and Product Line Diversity

Since its founding in 2011, Ocpuritech has rose as an international leader focusing on industrial and commercial water purification. With two standardized factories spanning over 10,000 square meters, Ocpuritech supplies high-quality sewage water treatment machinery designed for diverse markets in Southeast Asia, Africa, and South America.

Their product portfolio includes:

- Remote-control RO systems and brackish water RO units

- Sea water desalination and ultrafiltration (UF) systems

- Nanofiltration and electrodeionization (EDI) ultrapure water solutions

- Pretreatment systems featuring sand, carbon filters, and chemical softeners

I have personally witnessed projects where Ocpuritech’s modular systems were deployed in agricultural recycling, boiler feed water, hospitals, and beverage manufacturing lines with excellent operational feedback, regulatory compliance, and environmental impact reduction.

Their commitment to delivering cost-effective and technically advanced water solutions underscores Mrs. Carrie Chan’s vision: “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.”

Applications: From Desalination to Specialized Water Use

The capabilities of modern sewage water treatment machinery extend beyond conventional wastewater management, including several niche and high-demand areas:

- Seawater desalination units providing potable water for coastal industries and communities

- Point-of-use RO systems catering to portable and emergency water needs, including space drinking water supply solutions

- Industrial process water recycling, significantly reducing freshwater withdrawal and wastewater discharge costs

Our operational data from industrial clients highlights water recovery efficiencies often exceeding 75% when pretreatment and chemical softening protocols are correctly implemented (Saltworks Tech, 2023 Chemical Softening).

This mix of advanced membrane technology, modularity, and strategic pretreatment yields cost savings, regulatory compliance, and environmental benefits across sectors.

FAQ

Q1: What are the main benefits of using reverse osmosis in sewage water treatment?

Reverse osmosis efficiently removes dissolved solids and contaminants, producing high-quality treated water while reducing energy and water consumption compared to traditional methods.

Q2: How does pretreatment improve the performance of sewage water treatment machinery?

Pretreatment reduces membrane fouling by removing suspended solids, hardness, and other impurities, extending membrane lifespan and lowering maintenance costs.

Q3: What role does UV sterilization play in industrial water treatment?

UV sterilization provides chemical-free disinfection that effectively inactivates pathogens, enhancing water safety and ensuring compliance with microbial standards.

Q4: Are modular containerized water treatment systems suitable for remote locations?

Yes, modular systems are compact, portable, and easily deployed in sites with space or logistical constraints, such as offshore platforms or disaster relief zones.

Q5: How can chemical softening maximize RO recovery?

Chemical softening removes scale-forming compounds, thereby increasing RO membrane recovery rates and reducing osmotic pressure limitations.

Q6: What industries benefit most from advanced sewage water treatment machinery?

Industries such as pharmaceuticals, food and beverage, agriculture, and chemical manufacturing benefit from efficient and compliant water treatment technologies.

Q7: How does membrane size affect the cost and efficiency of RO systems?

Larger diameter membranes increase surface area and permeability, which can lower life cycle costs and improve treatment performance.

Q8: What maintenance is necessary for UV water sterilization systems?

Regular cleaning, sensor calibration, and lamp replacement are essential to maintain UV intensity and ensure effective disinfection.

Q9: Can sewage water treatment machinery handle seawater desalination?

Yes, specialized RO systems and pretreatment modules are designed to process seawater, converting it into potable or process water.

Q10: What environmentally friendly practices are integrated into modern water treatment systems?

Modern systems use energy-efficient membranes, minimize chemical use, optimize water recovery, and employ chemical-free disinfection like UV technology to reduce environmental impact.