Understanding the Role of RO Systems in Modern Industrial and Commercial Water Treatment

In today’s industrial and commercial sectors, the quality and reliability of water treatment systems are crucial. Among the various technologies available, the RO system of water treatment stands out for its superior capability to deliver purified water by efficiently removing dissolved impurities, contaminants, and microorganisms. This article provides a comprehensive understanding of RO technology, explores multiple equipment categories tailored to diverse capacity needs, and discusses practical applications across industries.

Core Technology of RO Membrane Systems

Reverse Osmosis (RO) is a cutting-edge purification technology using a semi-permeable membrane to separate water molecules from dissolved solids and contaminants under applied pressure. Key components include:

- Pre-filtration Units: Remove larger particulates and sediments to protect the membrane and prolong its life.

- RO Membrane Modules: Central to the process, these membranes typically filter out 95-99% of salts, heavy metals, bacteria, viruses, and organic compounds.

- Post-filtration and Polishing Filters: Fine-tune water quality, enhancing taste and removing residual impurities.

- Storage and Distribution: Tanks equipped for purified water storage and consistent supply.

Modern RO systems come in multiple capacity tiers—from compact units producing a few hundred liters per hour, suited for small commercial facilities, to large-scale modular plants handling several thousand cubic meters daily for industrial use.

Additional Water Treatment Equipment

1. Filtration and Softening Systems

To complement RO membranes, filtration systems such as multimedia filters and carbon filters remove turbidity, chlorine, and organic contaminants that can damage membranes. Softening units reduce hardness by exchanging calcium and magnesium ions, protecting RO components and enhancing product water quality. These systems are essential across all scales, improving membrane efficiency and equipment longevity.

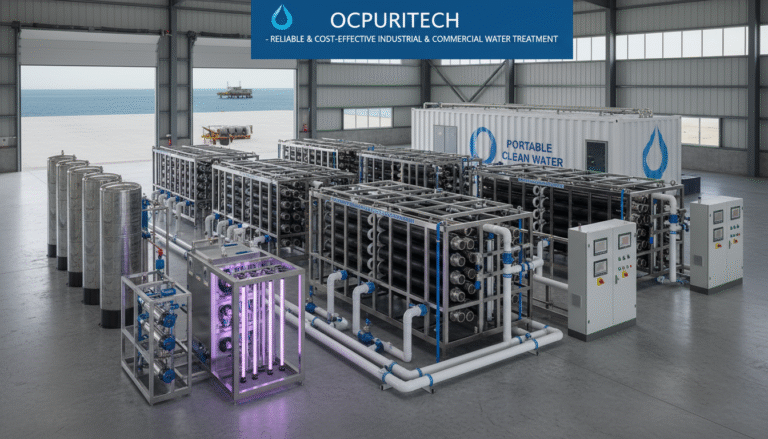

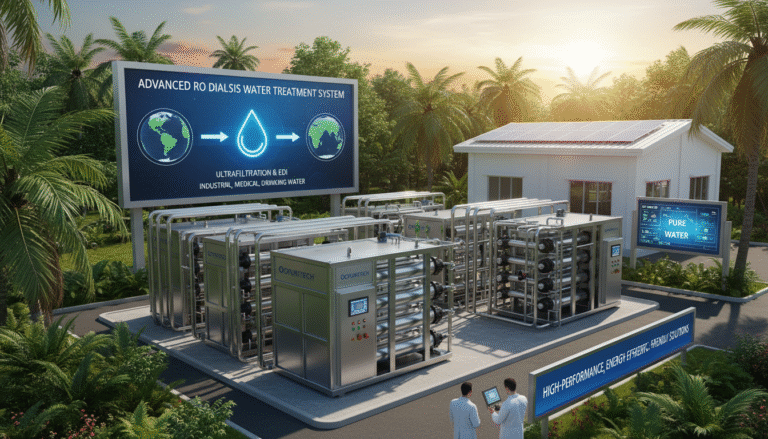

2. Containerized RO Systems

For applications requiring mobility or rapid deployment, containerized RO systems offer a compact, plug-and-play solution. Typically installed in standardized shipping containers, they incorporate pre-treatment, RO membranes, and control systems within a weather-resistant enclosure. Capacities range widely, including:

- Small portable units for remote sites or emergency use (~500-2000 liters/day)

- Medium industrial containers for municipal or small industrial plants (~10,000-50,000 liters/day)

- Large-scale desalination containers for coastal or island installations (>100,000 liters/day)

These systems facilitate quick setup with minimal civil works, making them ideal where infrastructure is limited.

3. Cleaning and Disinfection Modules

To maintain optimal membrane performance and microbial safety, integrated cleaning protocols and disinfection methods are crucial. Ultraviolet (UV) disinfection units are widely used to eradicate bacteria and viruses post-filtration, ensuring microbiologically safe water without chemical residues. Automated cleaning cycles using chemical agents also help keep membranes free of fouling, enhancing lifespan and reducing downtime.

Technical Specifications and Performance Ranges

| Equipment Type | Capacity Range (Liters per Hour) | Typical Application Sectors | Key Advantages |

|---|---|---|---|

| Compact RO Membrane Units | 200 – 2000 | Small restaurants, clinics, offices | Low footprint, easy installation, cost-effective |

| Modular Industrial RO Systems | 5,000 – 50,000 | Food & beverage, pharmaceuticals, electronics | Scalable design, high recovery rates, regulatory compliance |

| Containerized RO Plants | 10,000 – 200,000+ | Municipal water, seawater desalination, emergency supply | Mobility, turnkey operation, robustness in harsh conditions |

Manufacturers’ Expertise and Quality Assurance

Industry-leading manufacturers of RO water treatment systems combine decades of R&D with stringent quality controls. Utilizing advanced membrane technology sourced from globally recognized suppliers, coupled with robust fabrication standards, they ensure equipment durability and performance consistency. Many have obtained certifications aligning with international water treatment and safety standards, providing customers with confidence and peace of mind.

Diverse Applications of Industrial RO Systems

The versatility of RO technology makes it applicable across a variety of demanding scenarios:

- Seawater Desalination: With increasing freshwater scarcity, RO desalination converts brackish or seawater into potable and process water, supporting coastal industries and municipalities.

- Portable Drinking Water Systems: Compact and containerized RO units are deployed for disaster relief, military operations, and remote communities requiring access to safe drinking water.

- Specialized Water Supply: In aerospace and research sectors, RO systems ensure ultrapure water for space missions or laboratory-grade applications.

Practical Insights from Field Experience

In my consultancy engagements with a mid-sized food processing facility, integrating a two-stage RO membrane system coupled with a softening pre-treatment led to a 30% reduction in water consumption by enabling effective reuse of process water. This not only resulted in substantial cost savings but also ensured compliance with increasingly strict environmental discharge regulations.

Additionally, I observed that deploying containerized RO systems in remote mining operations enabled onsite water recycling, dramatically reducing reliance on trucked-in water and minimizing environmental impact. The modularity of these systems allowed scaling capacity in line with operational demands without extensive infrastructure investments.

Conclusion

The RO system of water treatment embodies a cornerstone technology in modern industrial and commercial water purification. Its adaptability across capacity ranges and configuration flexibility meet diverse water quality challenges—from municipal supply enhancement to specialized industrial needs. When combined with complementary filtration and disinfection modules, RO systems offer a reliable, cost-efficient path to achieving high-purity water.

Selecting an appropriate system involves assessing operational scale, feed water quality, maintenance capabilities, and regulatory requirements. Leveraging trusted manufacturers’ expertise coupled with proven technology can significantly enhance process efficiency and sustainability.

Based on research from Grand View Research, Research and Markets, and Technavio reports on “RO system water treatment basics,” “reverse osmosis technology industrial use,” and “commercial water purification RO system.” These sources confirm RO technology’s high efficiency and broad industrial applications (2022–2025).