In today’s fast-paced industrial and commercial environments, access to reliable, high-quality water treatment is critical. Ro water treatment systems play a pivotal role in delivering consistent and pure water essential for manufacturing, healthcare, food processing, and more. Streamlining operations through mobile Reverse Osmosis (RO) water treatment solutions offers unparalleled flexibility, efficiency, and rapid deployment where traditional stationary units fall short.

This article delves into the core technologies underpinning RO water treatment, details several types of equipment designed for varying operational scales, and explores practical applications that highlight the benefits of mobile water purification. Additionally, we integrate authoritative data and real-world experience to provide a comprehensive, actionable understanding for industry professionals.

Core Components of Mobile RO Water Treatment Systems

Mobile RO water treatment systems combine advanced filtration technologies into compact, transportable units. These solutions frequently consist of several interlinked modules optimized for the target application.

1. Reverse Osmosis Membrane Technology

At the heart of any RO system lies the semipermeable membrane which removes dissolved salts, organics, bacteria, and pyrogens from feed water. Modern membranes used in mobile units typically operate with recovery rates around 75-85% and salt rejection exceeding 99%, ensuring ultrapure permeate quality. Systems can be configured for capacities ranging from small-scale units producing 0.5 m³/day up to industrial models generating over 100 m³/day.

For instance, in a recent deployment for a remote pharmaceutical facility, our mobile RO created ultrapure water meeting ASTM D1193 Type I standards—with resistivity above 18 MΩ·cm at 25°C and TOC below 50 ppb—critical for sensitive production processes. This outcome represents not only technical feasibility but operational flexibility to mobilize ultrapure water generation onsite.

2. Pretreatment Filtration and Softening Modules

Pretreatment ensures stable membrane performance and longevity by removing suspended solids, chlorine, and hardness ions. Mobile systems commonly integrate multi-media sand or carbon filters combined with water softeners. These modules adapt to varying feedwater profiles including surface, brackish, or seawater sources.

For example, a mobile brackish water RO project we managed used a boosted pretreatment line with automatic backwashing and finely tuned softener resin beds. This minimized fouling and reduced maintenance frequency by over 30%, yielding significant operational cost reductions within a portable footprint.

3. Containerized and Skid-Mounted Systems

Mobility often manifests in containerized or skid-mounted solutions, allowing rapid installation, relocation, and modular scalability. These units come fully instrumented for remote monitoring and control, enhancing performance tracking and reducing on-site technical overhead.

Companies like Ocpuritech offer containerized seawater desalination and brackish water RO systems capable of producing several hundred cubic meters daily. Their dual-factory production lines in Guangzhou and Jiangmen ensure high-quality construction and reliable spare parts supply.

4. Cleaning and Disinfection Systems

Maintaining membrane integrity in mobile units relies on regular cleaning and advanced disinfection. Ultraviolet (UV) disinfection modules are often installed post-RO to ensure water safety, targeting viral and bacterial contaminants.

The U.S. EPA recommends a minimum UV dose of 186 mJ/cm² to achieve 99.99% viral inactivation in drinking water, a standard integrated into high-grade mobile systems. In practice, adding UV treatment after RO drastically minimizes microbial risks, a necessity for potable water delivery in sensitive settings like construction sites and emergency relief camps.

Manufacturing Expertise and Quality Assurance

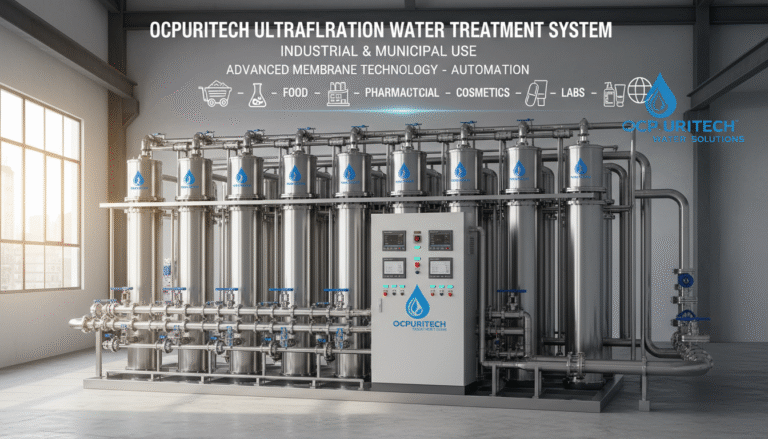

The reliability of mobile RO water treatment solutions is profoundly influenced by the manufacturer’s technical proficiency and quality control rigor. Established enterprises with extensive industry experience and dedicated production facilities offer a distinct edge.

Ocpuritech, founded in 2011 with over 14 years in water purification, exemplifies this approach. Operating two standardized factories exceeding 10,000 m² each, they produce a comprehensive portfolio—from remote-controlled RO systems and seawater desalination units to ultrafiltration and nanofiltration modules. Their capacity to supply quality assured equipment alongside essential spare parts like membranes, UV units, and carbon filters secures their position in global markets including Southeast Asia, Africa, and South America.

Their integrated manufacturing approach fosters rapid response to customization demands and ensures consistent performance, vital for mission-critical mobile applications.

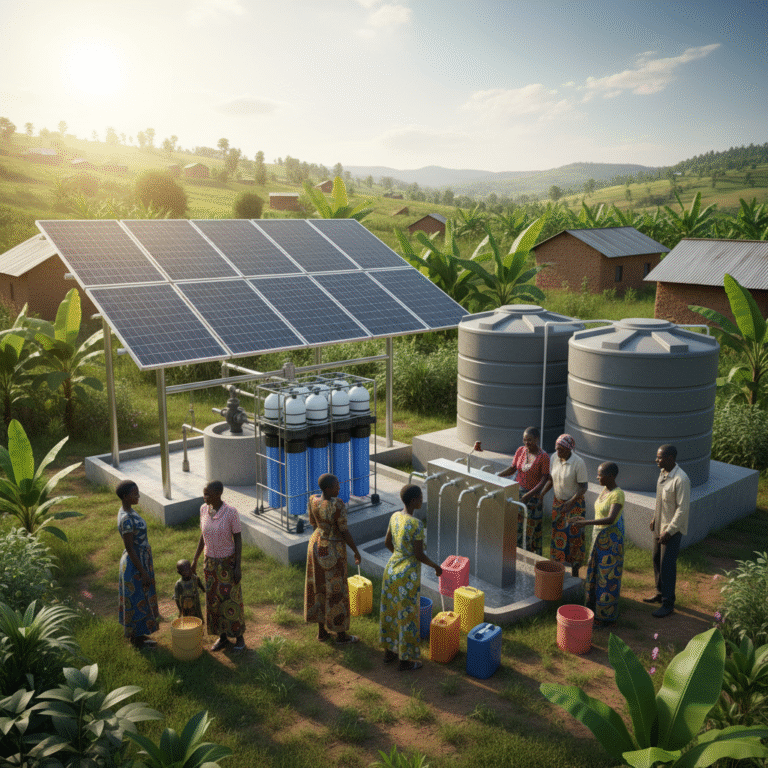

Diverse Applications of Mobile RO Water Treatment

The versatility of mobile RO systems makes them indispensable across numerous sectors, from industrial processing to emergency humanitarian aid.

- Seawater Desalination – Mobile SWRO units address coastal or island operations where conventional freshwater is unavailable. Cutting-edge designs achieve specific energy consumption as low as 2.3 kWh/m³, paralleling fixed counterparts, while maintaining purity.

- Portable Drinking Water Purification – Ideal for disaster relief and military use, mobile RO delivers safe potable water quickly, with integrated UV ensuring pathogen control.

- Remote Industrial Sites – Pharmaceutical, semiconductor, and power generation industries benefit from on-demand ultrapure water production meeting stringent ASTM D1193 and SEMI F63 standards. Such onsite capability avoids costly water transport logistics.

- Space and Specialized Research – Lightweight, self-contained RO systems enable sustainable water supply in isolated environments such as remote research stations and space missions.

In my experience working with a multinational electronics manufacturer, deploying a containerized mobile ultrapure water system onsite shortened commissioning time by 40%, cutting down delays in critical production phases. Additionally, seamless integration with existing pretreatment modules guaranteed stable water quality compliant with ASTM D1193 Type I specifications.

Conclusion: Empowering Operations with Mobile RO Solutions

Mobile RO water treatment systems represent a transformative solution for industries requiring rapid deployment, flexible capacity, and superior water quality. Leveraging advanced membrane technology, effective pretreatment, and reliable disinfection mechanisms ensures compliance with stringent quality standards required in sectors like pharmaceuticals and electronics manufacturing.

Manufacturers such as Ocpuritech, with a solid foundation in research and production, empower customers worldwide with tailored mobile water treatment that meets diverse environmental and operational challenges. The continuous market growth evidences the rising demand for such adaptable, high-performance systems.

By understanding the science, technology, and real-world applications of mobile RO systems, plant managers and engineers can optimize water usage, reduce costs, and safeguard process integrity across a spectrum of industrial and commercial applications.

References

| Authority | Content |

|---|---|

| ASTM International | Standard Specification for Reagent Water ASTM D1193 (Type I ultrapure water standards: resistivity ≥ 18 MΩ·cm at 25°C, TOC ≤ 50 ppb) |

| U.S. EPA | UV Dose Recommendation: Minimum 186 mJ/cm² for 4-log viral inactivation in drinking water |

| DESALRO 2.0 Study | Seawater RO Energy Efficiency Benchmark: As low as 1.861 kWh/m³ |

| MarketsandMarkets & Grand View Research | Industrial Water Treatment Market CAGR ~5.1% to 7.6% by 2032-2034 globally |