Introduction: The Imperative of Industrial Water Treatment

Industrial water treatment stands as a pillar of sustainable manufacturing and environmental stewardship. For industries spanning manufacturing, energy, food processing, and pharmaceuticals, efficiently managing water quality is not only a regulatory mandate but a critical driver for operational excellence and cost containment. At the core of this pursuit are specialized water treatment positions — dedicated engineering roles equipped to deploy, monitor, and optimize complex water treatment systems that ensure purity, compliance, and reuse capability.

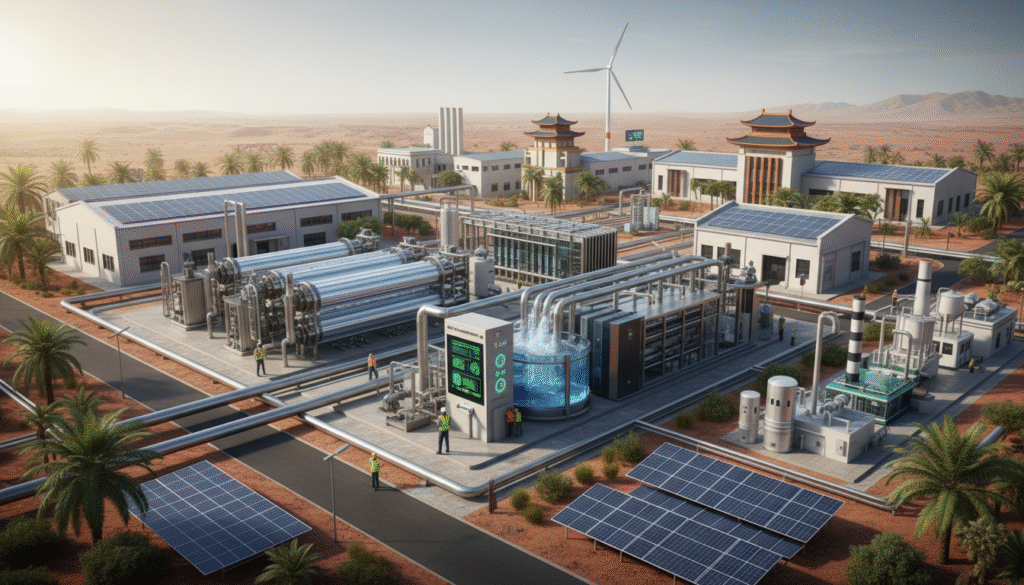

Our industry’s relentless focus on innovation and environmental responsibility aligns with the global trend toward smarter, more energy-efficient water management. This article delves into the landscape of industrial water treatment, explores key equipment and technologies, highlights competitive edges from technical innovation, and provides actionable insights relevant to markets especially in Africa, Southeast Asia, South America, and Asia.

Comprehensive Product Line for Industrial Water Treatment Needs

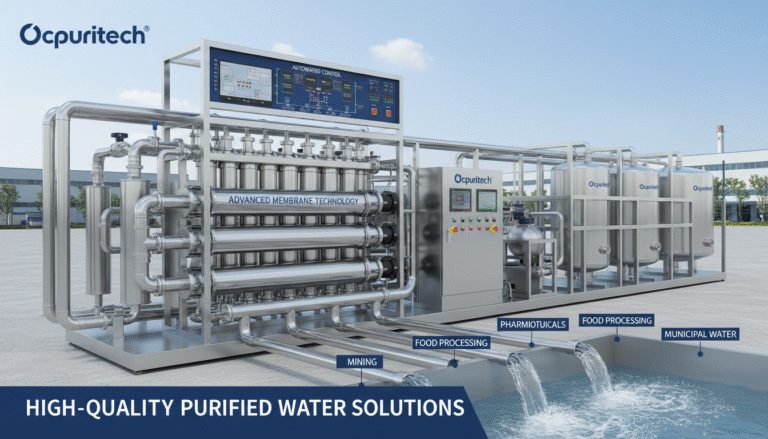

1. Reverse Osmosis (RO) Systems

Reverse Osmosis systems remain the cornerstone of high-efficiency industrial water purification. Utilizing semi-permeable membranes, RO technology removes dissolved solids, salts, organics, and microorganisms to deliver ultrapure water suitable for critical processes. Modern RO units incorporate energy recovery devices, automated membrane cleaning, and real-time monitoring.

Typical parameters include feed water TDS reduction up to 98%, operating pressures between 8-16 bar, and flow capacities scaling from 1 to 500 m³/h, adaptable to different industrial scales. Industries benefiting the most encompass power generation, semiconductor manufacturing, and beverage production.

2. Ultrafiltration (UF) Systems

Ultrafiltration technology offers membrane filtration targeting suspended solids, colloids, and pathogens without removing dissolved salts. UF membranes operate with pore sizes typically between 0.01 to 0.1 microns, effectively reducing turbidity and microbial load. This process is frequently deployed as a pre-treatment step for RO or as a standalone solution for wastewater reuse in textile and pharmaceutical sectors.

The modular design and chemical resistance of UF membranes enable scalability and longevity even under fluctuating feed water quality.

3. Electrodeionization (EDI) Systems

To achieve ultrapure water essential for microelectronics and biotech, Electrodeionization combines ion exchange resins with electrical current to continuously remove ionized species without consumable chemicals. EDI systems offer advantages in automation, lower chemical costs, and reduced waste generation.

Typical delivered water resistivity exceeds 18 MΩ·cm with system capacities customizable from small laboratory setups to large manufacturing sites.

4. Pretreatment & Softening Water Systems

Pretreatment systems including multimedia filtration, activated carbon filters, and water softening units are critical for protecting downstream membranes and equipment. Softening processes reduce hardness ions such as calcium and magnesium via ion exchange or chemical dosing, preventing scaling.

Selection depends on feed water characteristics, with options for continuous regeneration softeners or salt-free conditioners for eco-conscious operations.

Technological Innovation Driving Competitive Advantages

Innovation in water treatment technology transforms operational efficiency and sustainability. Below is a comparative overview of traditional versus advanced systems highlighting enhancements:

| Feature | Traditional Systems | Advanced Systems |

|---|---|---|

| Energy Consumption | High (No recovery devices) | Significantly reduced via energy recovery units |

| Chemical Usage | Periodic chemical dosing, high consumption | Automated cleaning and EDI reduce/eliminate chemicals |

| Process Monitoring | Manual sampling | Real-time sensors and IoT-enabled diagnostics |

| Water Recovery Rate | Typically 50-75% | Up to 85% with zero liquid discharge options |

My experience managing a municipal wastewater reuse project showed that integrating high-recovery RO membranes with automated CIP (clean-in-place) routines reduced downtime by 30% while saving approximately 20% in energy costs annually. Such efficiencies translate directly to lower total cost of ownership and faster ROI for customers.

Industry Position & Global Market Outlook

The water treatment industry is witnessing dynamic growth, propelled by rising industrialization, stricter environmental regulations, and growing demand for water reuse. According to Grand View Research, the global enterprise water treatment market in 2024 is poised to sustain a compound annual growth rate exceeding 12% through 2030. The Asia Pacific region leads growth momentum, driven by rapid industrial expansion and urban water challenges.

The global enterprise software market—an adjacent sector reflecting technology trends—is projected to reach over $517 billion by 2030, with Asia Pacific growing at a CAGR of 13.7%. Similar growth trajectories for water treatment technologies suggest robust investment and innovation waves.

Source: Grand View Research – Enterprise Software Market Size & Growth 2030

Regions such as Africa, Southeast Asia, and South America present significant opportunities where industrial growth is escalating alongside the urgent need for sustainable water management solutions. Providers that embed local contextual knowledge and adaptable systems edge out competitors in these frontier markets.

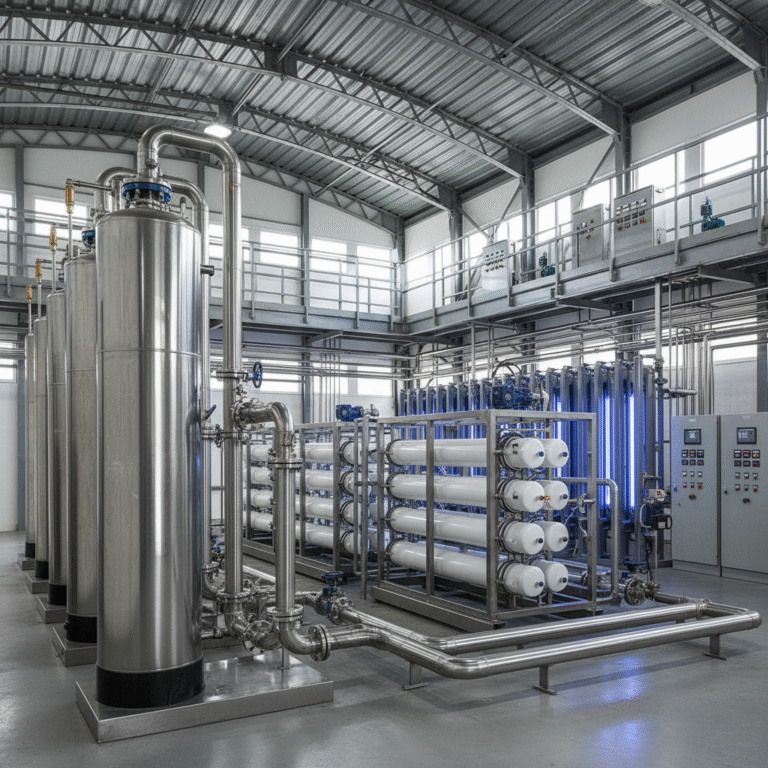

Manufacturing & R&D Excellence

State-of-the-art manufacturing facilities equipped with automated fabrication, stringent QA/QC standards, and lean inventory principles underpin product consistency and scalability. Dedicated R&D teams collaborate with academic institutions and industrial partners to pioneer breakthroughs in membrane materials, energy-efficient system design, and digital water management platforms.

For instance, in a joint development program focused on nano-engineered membranes for brackish water applications, pilot installations reported a 15% increase in flux capacity while maintaining rejection rates above 99.5%. Such innovations shorten time-to-market and improve system lifetime for end-users.

Customer Success Stories Illustrating Real-World Impact

In one Southeast Asian beverage facility, deploying a hybrid ultrafiltration and RO system led to a 40% reduction in freshwater withdrawal and a 25% cut in wastewater discharge, meeting both environmental targets and operational cost goals within the first year. The dedicated water treatment positions managed intricate process control adjustments, ensuring continuous compliance despite fluctuating raw water quality.

A South American mining operation integrated an electrodeionization system replacing chemical demineralizers, which lowered chemical handling risks and reduced effluent hazardous load by 80%. This upgrade enhanced worker safety while improving water reuse rates.

Commitment to Environmental Sustainability

Sustainability is embedded across the water treatment solutions offered: from adopting low-energy membrane technologies and minimizing wastewater brine to applying eco-friendly materials and enabling circular water use. This holistic approach supports clients’ environmental goals and contributes to broader ecological conservation.

Operational strategies include resource recovery, such as reclaiming minerals from wastewater streams, and implementing digital water footprint tracking for continuous improvement.

Engage with Experts to Optimize Your Water Treatment Strategy

Choosing the right industrial water treatment setup requires a clear understanding of site-specific water chemistry, production demands, regulatory frameworks, and long-term sustainability aspirations. Our industry-experienced consultants stand ready to develop tailored water treatment positions and system configurations that maximize performance and ROI.

- Comprehensive water quality assessment and pilot testing

- Custom system design integrating latest membrane and monitoring technologies

- Turnkey installation and proactive maintenance plans

- Training programs for operators aligned with advanced treatment techniques

Engage through multiple channels — direct consultation via website contact forms, phone-based technical support, or on-site evaluation visits. The goal is empowering decision-makers, engineers, and procurement professionals to champion smarter, greener water treatment operations worldwide.

Authoritative Data Source

Based on research from Grand View Research on the enterprise software market, which parallels technology developments impacting industrial water treatment, the global market is expanding rapidly with a CAGR of 12.1% through 2030. The Asia Pacific region is the fastest-growing market with a 13.7% CAGR, and North America retains a leading share with over 41% market presence.

This data highlights the macroeconomic trends driving innovation and demand in related industrial technology sectors, including water treatment.

Source: Grand View Research – Enterprise Software Market Size, Share, Growth Report 2030