In the realm of wastewater management, the pretreatment septic system cost is a critical consideration for industrial and commercial projects aiming for efficient and environmentally sound sewage solutions. Pretreatment systems play a pivotal role in flocculating solids and mitigating contaminants before wastewater enters the main septic tank, thereby enhancing system longevity and reducing environmental impact. Understanding the factors influencing these costs and how to optimize expenses is essential for successful project implementation.

Key Components Influencing Pretreatment Septic System Cost

Several technical and logistical factors impact the overall expense of a pretreatment septic system. These include system design complexity, capacity requirements, material quality, pretreatment technology employed, regulatory compliance, and installation site conditions. Each factor can variably influence equipment, labor, and maintenance costs.

- System capacity and scale: Larger capacities require bigger or multiple units, increasing material and installation expenses. An industrial site handling thousands of gallons daily differs vastly from a small commercial property.

- Technology type: Pretreatment systems may include screening, sedimentation, filtration, or advanced biological or chemical processes. High-tech ultrasonic or membrane-based pretreatment raises the initial investment.

- Material and equipment quality: Corrosion-resistant metals and durable composites enhance lifespan but increase upfront costs.

- Site-specific challenges: Terrain, accessibility, and soil conditions may require custom foundations or additional civil works.

- Labor and regulatory compliance: Skilled installation teams and adherence to local wastewater management codes can influence cost variability.

For example, in my experience managing a municipal septic upgrade project, selecting a modular, containerized pretreatment system with integrated filtration cut installation time and cost by nearly 15%. Optimization of system choice based on site specifics can yield significant economic advantage.

Technical Approaches to Optimize and Reduce Costs

Cost-saving in pretreatment septic systems is achievable through smart technology selection, modular design, and sustainable operation strategies. The integration of tried-and-certified pretreatment modalities can reduce unexpected maintenance costs and system failures.

- Modular Equipment Adoption: Modular systems enable scalability and phased investment. This approach was successfully applied in a remote industrial site, where incremental capacity expansion matched operational budget cycles without compromising treatment quality.

- Material Optimization: Utilizing composite FRP tanks instead of stainless steel reduced corrosion-related downtime and maintenance expenses in saline wastewater applications.

- Energy Efficiency: Incorporating low-energy-consuming components, such as gravity-fed filtration and UV disinfection compliant with NSF/ANSI 55 standards, lowers ongoing operational expensesNSF/ANSI standards.

- Regular Maintenance and Monitoring: Implementing remote control monitoring systems ensures timely interventions, reducing emergency repairs and improving lifecycle cost efficiency.

In one project, after switching to a blended sand filter and carbon filter pretreatment stage followed by UV disinfection, the facility reported a 20% reduction in chemical usage and a 30% drop in maintenance calls within the first year.

Leveraging Industry Expertise and Advanced Water Treatment Solutions

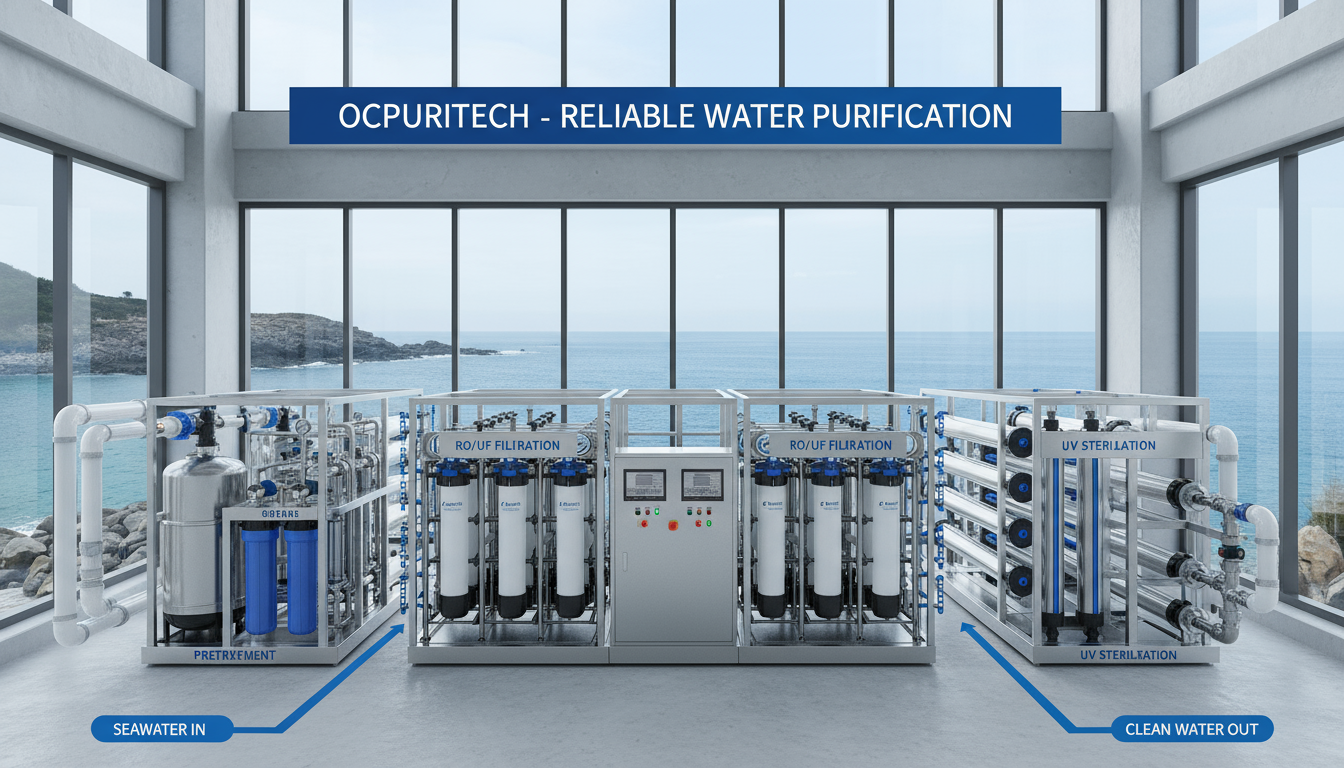

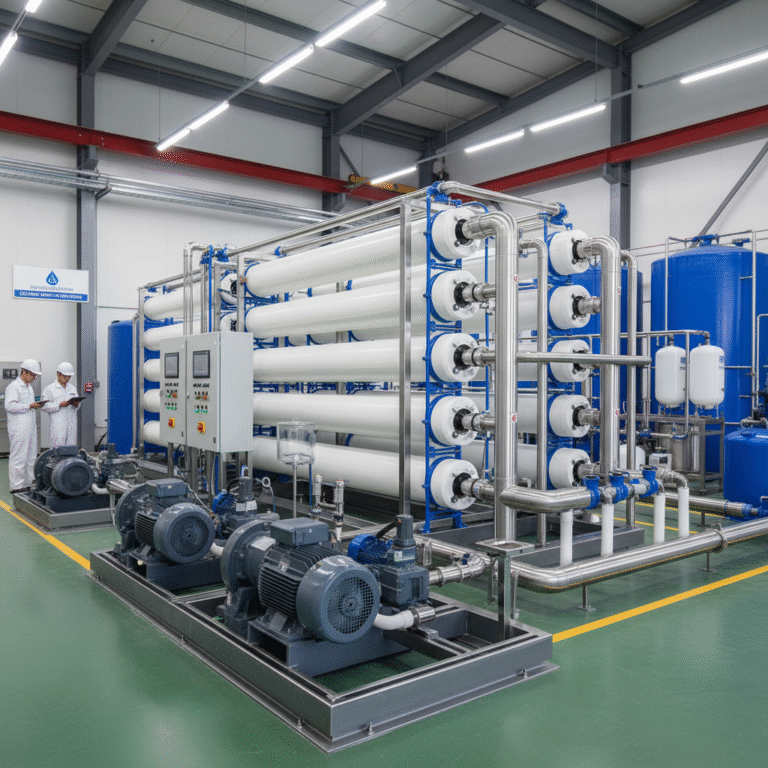

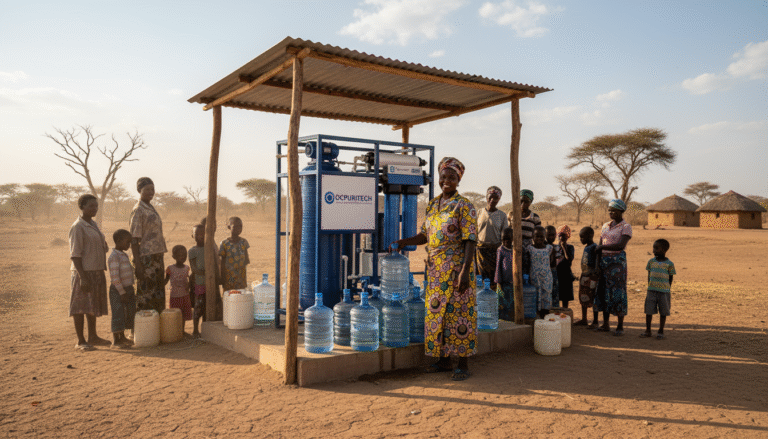

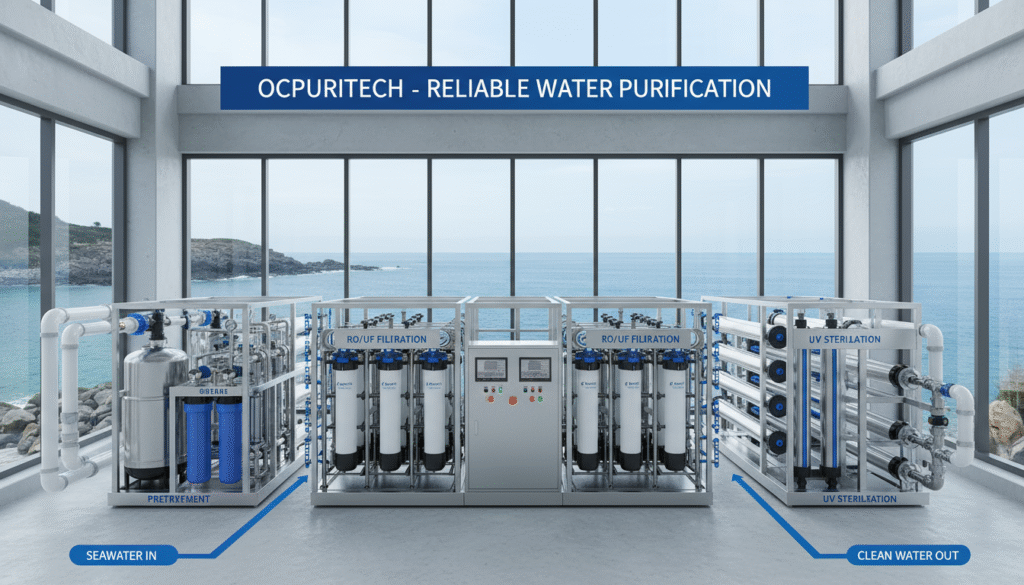

Leading water treatment manufacturers like Ocpuritech provide comprehensive solutions encompassing industrial water purification, including pretreatment septic systems designed with cutting-edge technologies. Their decade-long experience, standardized factories, and global presence underscore the reliability and adaptability of their solutions for diverse environments, from agricultural operations to high-purity water projects.

Ocpuritech’s modular designs support varied applications such as remote control reverse osmosis systems, ultrafiltration, and nanofiltration setups, delivering both cost-effective and high-performance options. Their commitment to environmental responsibility aligns with global regulatory standards, ensuring pretreatment systems not only meet cost efficiency goals but also sustainability requirements.

Moreover, ensuring compliance with regulatory frameworks such as the Recommended Standards for Water Works ensures operational safety, disinfection effectiveness using ultraviolet treatment, and proper filtration before discharge or reuse.

Practical Tips for Saving Money on Pretreatment Septic Systems

Cost-efficiency is not only about initial expenditure but also long-term operation and maintenance. Here are several actionable strategies:

- Conduct a thorough site assessment: Early evaluation can identify potential installation challenges, helping select the most suitable, cost-effective system configuration.

- Choose scalable systems: Systems with modular upgrades reduce upfront investment and allow adapting to future load increases without total replacement.

- Opt for energy-efficient components: Systems that reduce power consumption save appreciably on the total cost of ownership.

- Regular training and maintenance: Properly trained onsite operators minimize downtime and costly emergency repairs.

- Partner with experienced manufacturers: Trusted suppliers like Ocpuritech provide tested system designs, spare parts accessibility, and technical support that reduce lifecycle costs.

In one instance, integrating a UV disinfection system compliant with commercial UV standards not only improved effluent quality but also eliminated chemical disinfectants, leading to a 25% decrease in maintenance costs for a beverage manufacturing plant.

Frequently Asked Questions (FAQs)

Q1: What components typically make up a pretreatment septic system?

A pretreatment septic system usually includes screens for solids removal, sedimentation tanks, filtration units (such as sand or carbon filters), and disinfection modules like ultraviolet (UV) systems.

Q2: How does system capacity affect pretreatment septic system cost?

Larger capacity systems require bigger or multiple treatment units, increasing material, labor, and installation costs proportionally.

Q3: Can pretreatment reduce maintenance frequency and costs for septic systems?

Yes, effective pretreatment removes solids and contaminants, preventing clogging and damage downstream, thereby lowering maintenance needs and expenses.

Q4: What regulatory standards are important for pretreatment systems?

Standards such as NSF/ANSI 55 for UV disinfection and regional environmental protection agency regulations ensure treatment effectiveness and safety.

Q5: Are energy-efficient pretreatment systems available?

Yes, many modern systems incorporate low-energy filters, gravity-fed components, and LED UV disinfection to minimize operational energy use.

Q6: How does modular design benefit pretreatment system cost?

Modular designs allow phased investment and scalability, reducing upfront expenses and matching capacity growth to needs.

Q7: What maintenance practices save money over time?

Scheduled inspections, cleaning, filter replacements, and operator training prevent costly failures and extend system lifespan.

Q8: Why choose manufacturers like Ocpuritech for septic pretreatment solutions?

Ocpuritech offers proven expertise, comprehensive product lines, and global support, ensuring efficient and sustainable pretreatment system operation.

Q9: Is UV disinfection effective for septic pretreatment?

Yes, UV systems compliant with recognized certifications effectively inactivate pathogens, improving effluent quality without chemical use.

Q10: How to balance cost and environmental compliance in pretreatment systems?

Selecting designs that meet or exceed regulatory standards while employing energy-saving and low-maintenance technologies ensures cost-effective, eco-friendly treatment.