Yonder Trends: How to Install Reverse Osmosis Water Filtration Systems for Venues

Water purification is paramount for industrial and commercial venues seeking dependable, high-quality water treatment. Among various technologies, reverse osmosis (RO) water filtration systems stand out for their efficiency in removing contaminants and delivering clean water suitable for numerous applications. This article explores the essential components of RO-based water filtration systems, outlines equipment capacities across scales, and sheds light on installation considerations and uses across sectors.

Core Technology Modules in RO Water Filtration Systems

1. Reverse Osmosis Membrane Systems

The heart of a reverse osmosis system lies in its semi-permeable membranes, which separate dissolved solids and contaminants from feed water by molecular filtration. These membranes operate under pressure, typically between 150 to 600 psi, depending on feedwater characteristics.

- Technical parameters: Typical membrane rejection rates exceed 95-99% for total dissolved solids (TDS), chlorine, salts, and harmful microorganisms such as E. coli and Salmonella.

- Equipment scales: Available in modular configurations including small-scale units (500-2,000 gallons per day), mid-scale (2,000-10,000 GPD), and large industrial units (>10,000 GPD).

- Applications: Widely used in food and beverage manufacturing, pharmaceutical processing, and venue water services requiring impeccable purity standards.

- Performance advantage: NSF/ANSI 58 certification ensures compliance with stringent water treatment and safety standards, guaranteeing microbiological safety and predictable system output (NSF International, 2023).

2. Filtration and Softening Stages

Pre-treatment is essential to maximize RO membrane life and efficiency:

- Multimedia filtration: Removes suspended solids, sediments, and turbidity to protect downstream RO membranes.

- Activated carbon filtration: Eliminates chlorine and organic contaminants that can damage membranes.

- Water softening: Ion-exchange softeners mitigate scale formation by reducing hardness minerals such as calcium and magnesium.

- Capacity variations: Systems range from portable softening units for temporary venue setups to integrated pretreatment skids supporting high-capacity industrial RO arrays.

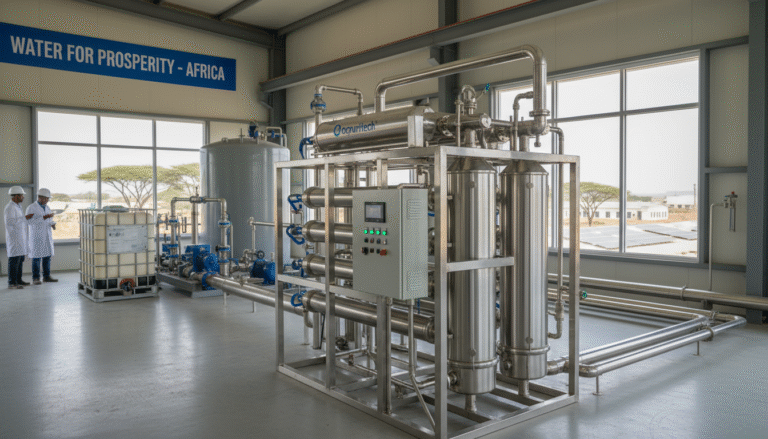

3. Containerized and Modular RO Systems

Space-efficient containerized systems house complete RO treatment lines within standard shipping containers or bespoke enclosures:

- Advantages: Simplified installation, mobility, and protection from environmental factors.

- Typical capacities: From 5,000 up to 100,000+ gallons per day, designed for rapid deployment in commercial venues, emergency water supply, or remote industrial sites.

- Industry uses: Event venues, large-scale catering, construction sites, and temporary workplaces benefit considerably from modular containerized RO solutions due to ease of plug-and-play installation.

4. Cleaning and Disinfection Technologies

To maintain system performance and hygiene standards, integrated cleaning protocols are vital. Advanced systems incorporate:

- Automated chemical cleaning cycles: Prevent scaling and biofouling of membranes.

- Ultraviolet (UV) sterilizers: Deploy UV-C light to inactivate pathogens post-filtration, ensuring microbiological safety for drinking applications.

- Monitoring and control: Sophisticated sensors track water quality parameters and signal maintenance needs, facilitating proactive system management.

Technical Expertise and Manufacturing Excellence Behind RO Systems

Leading manufacturers bring decades of specialized experience in water treatment, combining precision engineering with innovative materials science. High-quality RO systems undergo rigorous testing aligned with international standards such as NSF/ANSI 58, which specifies design, materials, and performance criteria for potable RO systems. This certification verifies that treated water is pathogen-free and complies with contaminant reduction requirements. Manufacturers’ dedication to research and quality control ensures system reliability and consistent output under diverse feedwater conditions.

Diverse Industrial & Commercial Applications of RO Water Filtration

Seawater Desalination for Industrial Use

RO technology is extensively applied in desalination plants, treating seawater to provide industrial process water or potable water in coastal industrial sites. Its ability to remove salt ions and complex impurities makes it indispensable for sectors like petrochemical plants, power stations, and metal processing facilities.

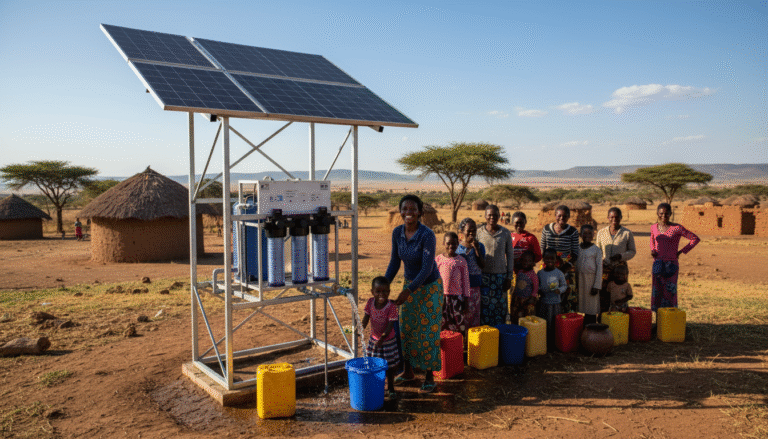

Portable and Emergency Water Treatment

Containerized RO units serve as portable water purification stations for temporary venues, disaster relief, and military operations. These units enable rapid water treatment capabilities where infrastructure is limited, ensuring safe drinking water on demand.

Specialized Environments: Space and Remote Locations

Advanced RO systems support closed-loop water recycling in space habitats, where water conservation is critical. Similarly, remote mining or exploration camps employ robust RO filtration to convert local water sources into safe, consumable water, ensuring operational continuity and personnel health.

Practical Insights on Installing RO Systems for Venues

Based on years of exposure to commercial venue projects, key installation considerations include:

- Site assessment: Evaluate feedwater quality, flow requirements, and space availability early to tailor system design.

- Modular design preference: Selecting modular, containerized systems significantly reduces installation time and civil works.

- Integration with existing plumbing: Seamlessly connect RO systems with venue water supply lines and ensure efficient drainage of reject water.

- Training and maintenance: Vendor-supported commissioning and operator training guarantee sustained system performance. Scheduled cleaning and performance monitoring are vital to avoid downtime.

For instance, in a recent hospitality venue installation I managed, incorporating a modular RO system with integrated UV sterilization improved water taste and safety, reducing bottled water purchases by 40% and lowering operational water costs within six months.

Conclusion

Installing reverse osmosis water filtration systems for venues involves understanding the multifaceted technology modules, selecting appropriate capacities, and leveraging certified, high-grade equipment designed for industrial and commercial environments. With applications spanning desalination, emergency supply, and specialized settings, RO systems are indispensable tools in the water treatment landscape.

Incorporating certified components compliant with relevant standards such as NSF/ANSI 58 assures safety and quality. Combining technical expertise with strategic installation delivers operational efficiency and cost-effectiveness—critical factors for venue operators prioritizing reliable water quality.

References

- NSF International – NSF/ANSI 58: Reverse Osmosis Drinking Water Treatment Systems, 2023